eastman quartz crusher

Aggregate specialist

quartz crushing

material

introduction

Quartzite is a non-metallic mineral, hard, wear-resistant, and chemically stable. Its main mineral component is silicon dioxide (SiO2), which is also a common silicate mineral with a hardness of 7. Quartz is widely used in industrial production such as glass, foundry, ceramics and refractory materials, smelting ferrosilicon, metallurgical flux, water treatment filter material, construction, chemical industry, abrasives, etc.

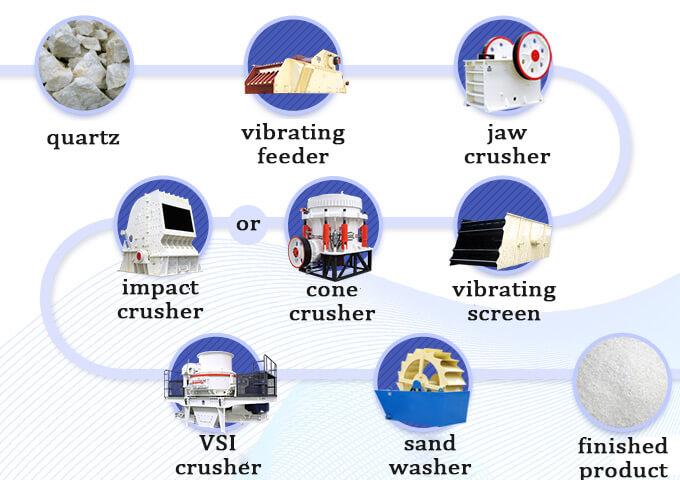

quartz crushing flow

Currently in the market, the commonly used specifications of quartz sand are 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh and other specifications. The above specifications include finished sand, finished crushed stone, and finished powder. Different specifications require different processing techniques, process design and equipment configuration.

The overall process of the quartz sand production line is: (silo) → feeder → jaw crusher (optional) → impact crusher or cone crusher → vibrating screen → sand making machine → sand washing machine ( optional) → finished sand.

The quartz sand making process is divided into three stages: coarse & fine crushing, sand making & screening, and sand washing & recycling.

The first stage: coarse & fine crushing

The materials are uniformly fed by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. After the coarse crushed materials are screened by the vibrating screen, they are conveyed by the belt conveyor to the cone crusher for medium and fine crushing.

The second stage: sand making & screening

The crushed materials are transported by the belt conveyor to the sand making machine for fine crushing. The fine crushed materials are then screened for coarse sand, medium sand, fine sand and other specifications through a circular vibrating screen.

The third stage: sand washing & recycling

For those with strict requirements on the powder content of sand, a sand washing machine can be installed behind the fine sand, and the sewage discharged from the sand washing machine can be recycled through the fine sand recovery device. On the one hand, it can reduce environmental pollution and increase the sand production output.

Additional

1. The flow of the quartz stone crushing line is: (silo) → vibrating feeder → (jaw crusher) → cone crusher → vibrating screen → finished crushed stone (using several layers of vibrating screens, you can get several size of the finished product).

2. The flow of the quartz sand grinding production line is roughly as follows: (silo) → vibrating feeder → jaw crusher → bucket elevator → electromagnetic vibration feeder → quartz sand mill → finished powder (using different grinding powder The equipment can get powder of different fineness).

Products Recommended

Jaw crusher

cone crusher

VSI sand maker

Sand Washer

related posts

Bentonite Processing Plant And Grinding Machine

Bentonite is a water-based clay mineral composed of montmorillonite, with a Mohs hardness of 1-2. It belongs to non-metallic minerals with a softer texture. Bentonite

Selection Of Lithium Ore Processing Plant Equipment

With the rapid development of the new energy market, there has been an explosive demand for energy metals. Lithium, as the “new energy metal of

High Frequency Electromagnetic Vibrating Screen

The GDS series electromagnetic high-frequency vibrating screen is a new screen-surface vibration screening machine. It adopts a new vibration method and transmission principle and utilizes

Dolomite Crushing Process And Grinding Equipment

Dolomite is abundant in nature and has a structure similar to calcite. It has good high-temperature resistance, corrosion resistance, and wear resistance. After a series

Pearlite Sand Production Line Equipment And Process Flow

Pearlite is an acidic karst mineral, non-toxic and odorless, with good fire resistance, sound absorption, chemical stability, etc. After the sand-making equipment process, perlite can applied in

Construction Brick Slag Crushing And Recycling Plant

Bricks slag refers to the leftover materials or waste bricks during the construction production process. It belongs to a type of construction waste. The construction

350-400TPH Complete Sand Making And Washing Plant

350-400TPH Granite Sand Making & Washing Plant Material: GraniteCapacity: 350-400TPHOutput size: 0-5mmInput Size: 0-780mm Schematic Diagram of Process Equipment Equipment Used

200TPH Sand-making Washing Plant

200TPH Granite Sand Making Plant Material: Granite, Hard Stones, ectCapacity: 200TPHOutput size: 0-5mm, 5-15mmInput Size: < 600mm Schematic Diagram of Process Equipment

200tph Wheel Type Sand Washing Plant

Capacity: 200t/h Material: 0-8mmpebble sand Sand application: construction, roads, bridges, etc Get Free Flow Design WhatsApp Instant Reply bucket type

500tph Quartz Sand Making Plant

500tph Quartz Sand Making Plant Capacity: 700t/h Material: quartz sand Equipment: Vibrating feeder, jaw crusher, sand making machine, circular vibrating

50tph sand making plant

50TPH sand making plant Capacity: 30-50t/h Material: River pebbles, granite, basalt and so on Equipment:Jaw crusher, fine crusher, sand making

350TPH Basalt Sand Making Plant

Basalt Sand plant Information Material: Basalt Capacity: 350TPH Output size: 0-5mm, 5-10mm, 10-20mm, 20-30mm Input Size: <400mm Project Details The