eastman Copper crusher

Mining specialist

Copper Processing

material

introduction

Since the 21st century, copper has been widely used and used in the electrical and electronic industries. It is mainly used in the manufacture of various electronic products such as mobile phones and computers, accounting for more than half of the total consumption. The types of copper ore mainly include natural copper, chalcopyrite, bornite, chalcocite, azurite, copper blue, etc.

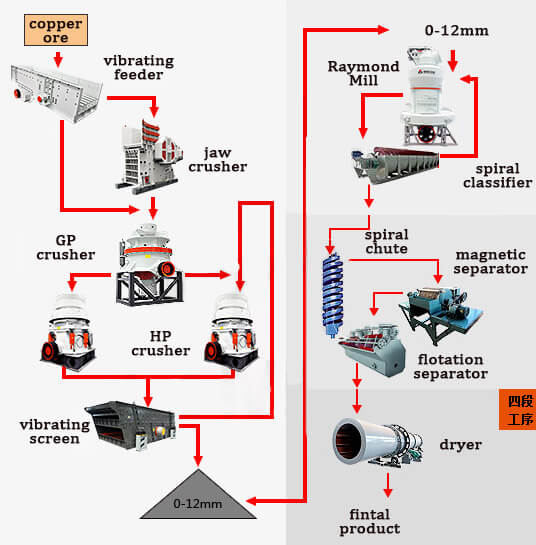

copper ore processing flow

Copper ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation. In the crushing process, three-stage closed-circuit crushing is a modern method suitable for high-hardness copper ore crushing. It can complete the crushing and partial dissociation of the ore, thereby improving the subsequent grinding efficiency; in the grinding process, two stages and one closed grinding design can make the copper ore grinding more fully; among the beneficiation processes, the more successful new processes that have emerged in recent years are mainly the mixed flotation process.

Additional

Eastman, a professional mine crushing solution provider, has focused on copper ore processing technology for 30 years, and provides you with a complete set of processing technology and equipment from copper ore to copper concentrate. Contact us to do free design.

The First Stage: Crushing & Screening

Large pieces of copper ore are evenly sent to the jaw crusher or coarse crushing mobile station (primary crushing) by the vibrating feeder for coarse crushing; After coarsely crushed copper ore are screened by vibrating screens, they are sent to a single-cylinder hydraulic cone crusher (second crushing) for intermediate crushing; The crushed copper ore materials are sent to a multi-cylinder hydraulic cone crusher for fine crushing;

Jaw crusher is mainly used for medium size crushing of various ores and bulk materials. It can crush materials with a compressive strength of up to 320Mpa, divided into two types: coarse crushing and fine crushing. Eastman has PE and PEX series jaw crushers with complete product specifications. Its feed size is 125mm~1020mm, and the single machine output is as high as 600TPH. It is an ideal choice for primary crushing equipment.

View More>>>

The GP (single-cylinder) hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines. Eastman single-cylinder hydraulic cone crusher is a high-efficiency crusher designed with advanced American technology and the performance of high-quality materials in the industry.

Automatic control and easy operation: using PCL touch screen operation and hydraulic adjustment of the discharge method, the discharge port is easy to adjust, easy to maintain, and it is more convenient and efficient to remove and replace the fixed cone, reducing downtime.

<<View More>>

HP (Multi-cylinder) hydraulic cone crusher is a new generation of high-efficiency hydraulic cone crusher based on nearly 30 years of crusher research and development experience, combined with domestic and foreign advanced technology, after several generations of product development and application. On the basis of the traditional multi-cylinder hydraulic cone crusher spindle fixed, eccentric sleeve rotating around the spindle structure and laminated crushing principle, the HP series has carried out a breakthrough optimization of the equipment structure, which significantly improves the use performance and crushing capacity of the equipment. The hydraulic lubrication system is designed to ensure the reliable operation of the equipment, while the operation control is more intelligent and humane.

<<View More>>

The tire-type mobile crushing station is widely used in the crushing process of mines. It can overcome the obstacles that the crushing site, environment, complex infrastructure and complex logistics bring to customers’ crushing operations, and truly provide customers with efficient and low-cost project operation hardware facilities . Eastman mobile tyre crusher has been successfully applied to mine crushing projects at home and abroad and plays an important role.

<<View More>>

The Second Stage: Grinding

The copper powder of 0-12mm sieved by the vibrating screen is evenly sent to the ball mill for grinding, and sieved by the spiral classifier.

Ball mill is a commonly used and efficient grinding equipment. It is suitable for grinding various ores such as iron ore, gold ore, copper ore and lead-zinc ore in metal beneficiation, and is used to grind the ore to below 0.075mm for subsequent beneficiation processes. According to different ways of discharging, it can be divided into grid type and overflow type. The grinding method can be divided into dry and wet grinding methods.

<<View More>>

Spiral classifier is a kind of equipment for mechanical classification based on the principle that the solid particles have different specific gravity, so the speed of precipitation in the liquid is different. It can filter the powder ground out of the mill, and then screw the coarse material into the feed port of the mill using a spiral blade, and discharge the filtered fine material from the overflow pipe.

<<View More>>

The Third Stage: Flotation + Drying

Magnetic separator is a device that uses appropriate strength of magnetism to select iron powder from powdered granules. Magnetic separators are widely used in beneficiation, suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of less than 3mm, and also used for coal, non-metallic minerals, building materials and other materials Iron removal operation is one of the most widely used and versatile machines in the industry.

<<View More>

The dryer is a commonly used equipment after the mine beneficiation. The drying drum adopts the principle of the drum forward and reverse to achieve the non-winding effect of the dried items, so that the moisture in the material can be removed.

<<View More>>