Jaw Crusher

[Capacity] 1-1120t/h

[Feed size] 100-1200mm

[Output size] 10-350mm

Capacity

1-1120t/h

Output Size

10-350mm

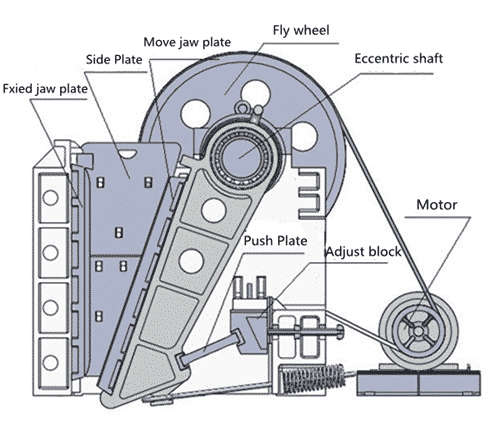

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit.

Applications

mining, quarry, construction waste recycling, aggregate making, etc.

Materials

Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of ores.

Hot Sale Models

PE150*250

Capacity: 1-3t/h

Feed size: 125mm

Discharge: 10-40mm

PE250*400

Capacity: 5-20t/h

Feed size: 210mm

Discharge: 20-80mm

PEX150*750

Capacity: 8-25t/h

Feed size: 120mm

Discharge: 18-48mm

Eastman jaw crusher series

Single & double toggle

We offers various efficient and provide single-toggle and double-toggle jaw crushers.

Wide range of options

Crushers models range in capacity from 1 TPH to 1130 TPH, feed openings start at 100 mm to 1200 mm.

jaw crusher working principle

suitable for all crushing demands

- Maximum productivity

Eastman Jaw crushers are engineered to deliver maximum productivity at the lowest operating costs. It is the best alternative to primary gyratory crushers, process the hard material efficiently. - High crushing capability

Jaw crushers are designed to process abrasive hard rock, with aggressively-shaped nip angle, it featurs the crushing ability that can consistently reduce high hardness materials the in the quarrying, mining, recycling, and building materials industries, increases uptime.

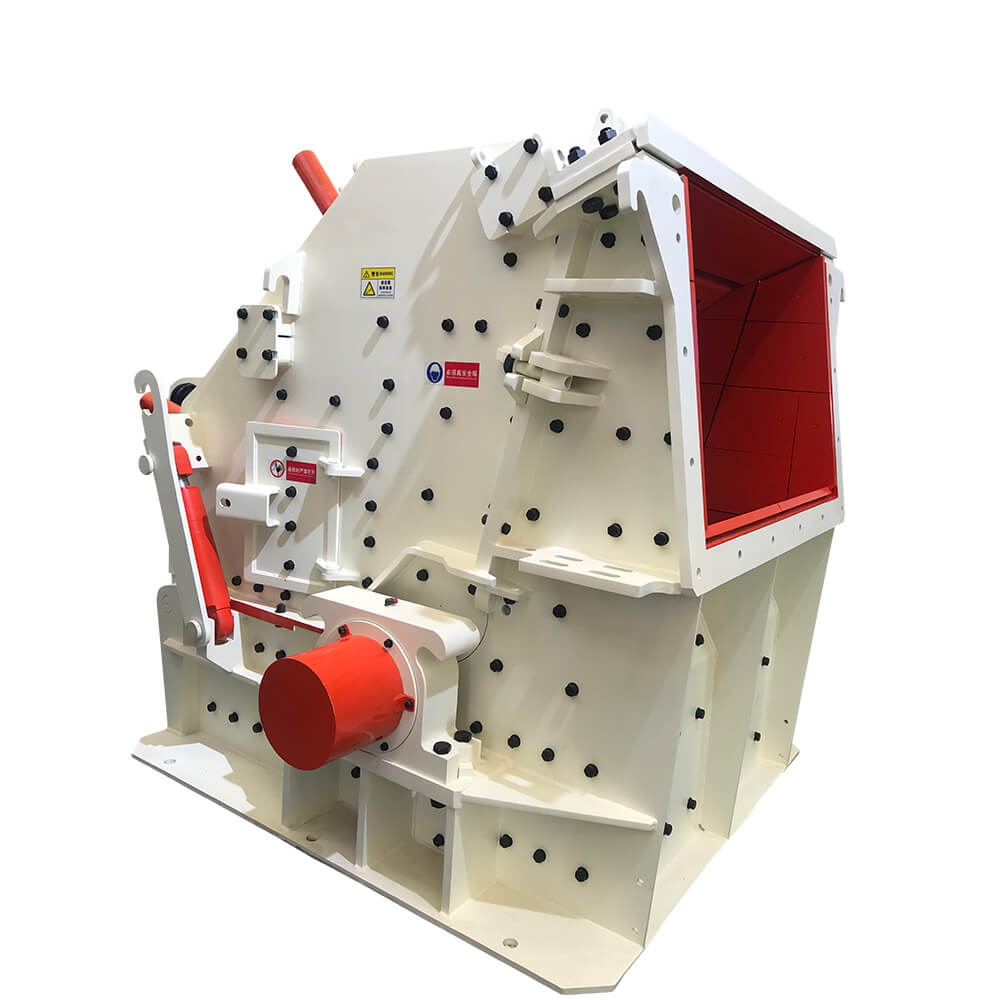

- Hydraulic protection system

In case of overload events, compared to the traditional one, the hydraulic jaw crusher can auto-cleaning the chamber avoid clog, auto-reset, no need entering the crusher and digging out. Hydraulic jaw crusher has a longer and safer working condition due to the hydraulic relief system. - Compact Structure

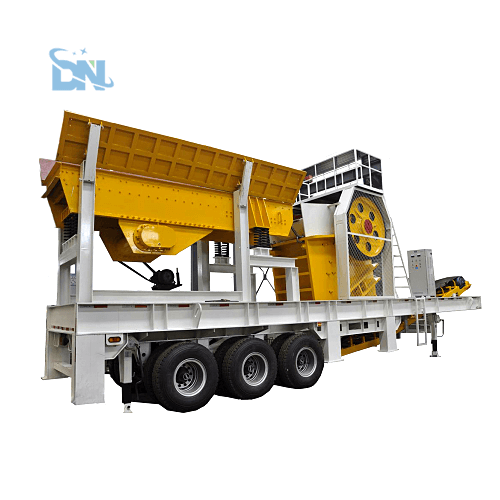

With the compact structure, jaw crushers no need a wide working spaces, it also available as mobile and portable versions (wheeled portable and track-mounted), great for underground mining and mobile crushing applications.

Jaw Crusher Technical specifications

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) | Overall dimension (LxWxH)(mm) |

| PE-150*250 | 150*250 | 130 | 10-60 | 3-15 | 5.5 | 2.2 | 1000x1450x900 |

| PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

| PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

| PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 1900x2192x1430 | |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 1750x2320x1724 | |

| PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 2162x2220x1723 |

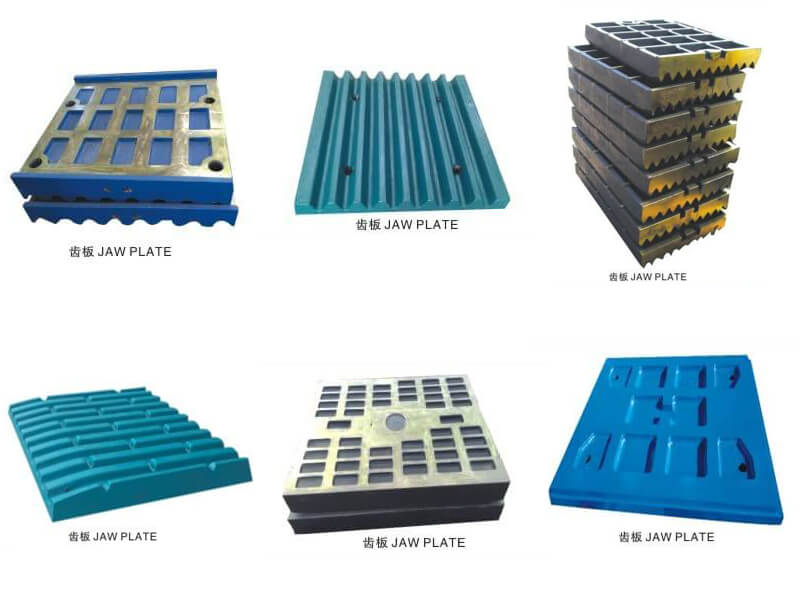

jaw crusher maintenance and parts

Eastman provides you with complete rock crushers and full list of components, original jaw crusher parts, form and function are a perfect fit.

If your equipment breaks down, the productivity of the whole factory will be threatened. Critical wear parts are shipped with the goods to ensure they are available when you need them and to reduce maintenance time.

Wear parts:

- Jaw plates

- Cheek plates

- Toggle plates

- Frame

- Hydraulic adjustment systems

- Lubrication device