crawler type mobile crusher

[Capacity] 70-650t/ht/h

[Feed size] 350-8500mm

[Output size] <100mm

Design as you need

Capacity

70-650t/h

Input size

350-800mm

Capacity

70-650t/h

Input size

350-850mm

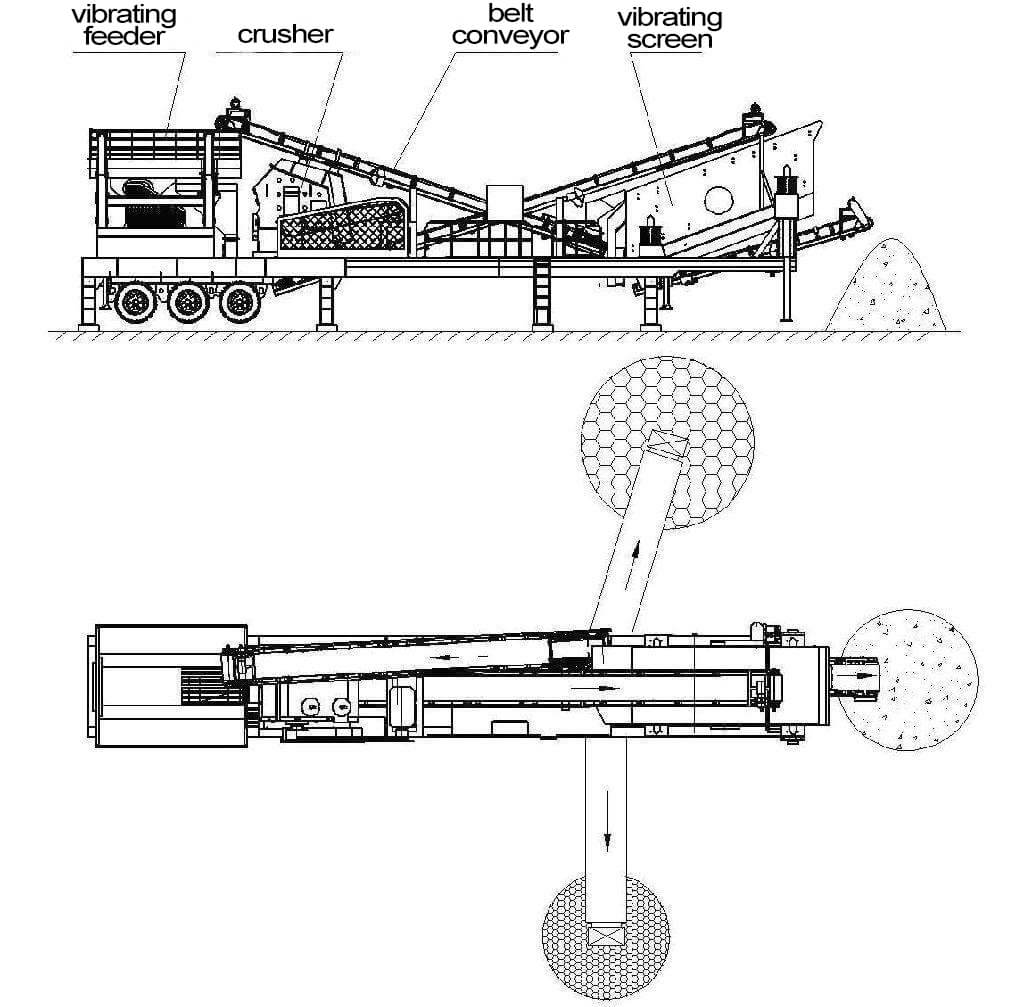

Crawler type mobile crusher is an advanced crusher plant, function and structure are highly customizable. Unlike other fixed rock crusher, it can be transfered easily in a varieties of rock crushing applications, like mining, building, construction, sand & gravel, construction waste, concrete, etc.

Configuration

Flexible combination of some of feeding, crushing, screening, sand making and so on systems.

Applications

mining, quarry, construction waste recycling, aggregate making, sand making, etc.

Highly customized for your needs

four main Functional systems

1. Continuous feeding

The most used feeder machine are hopper, vibrating feeder with grizzly bar.

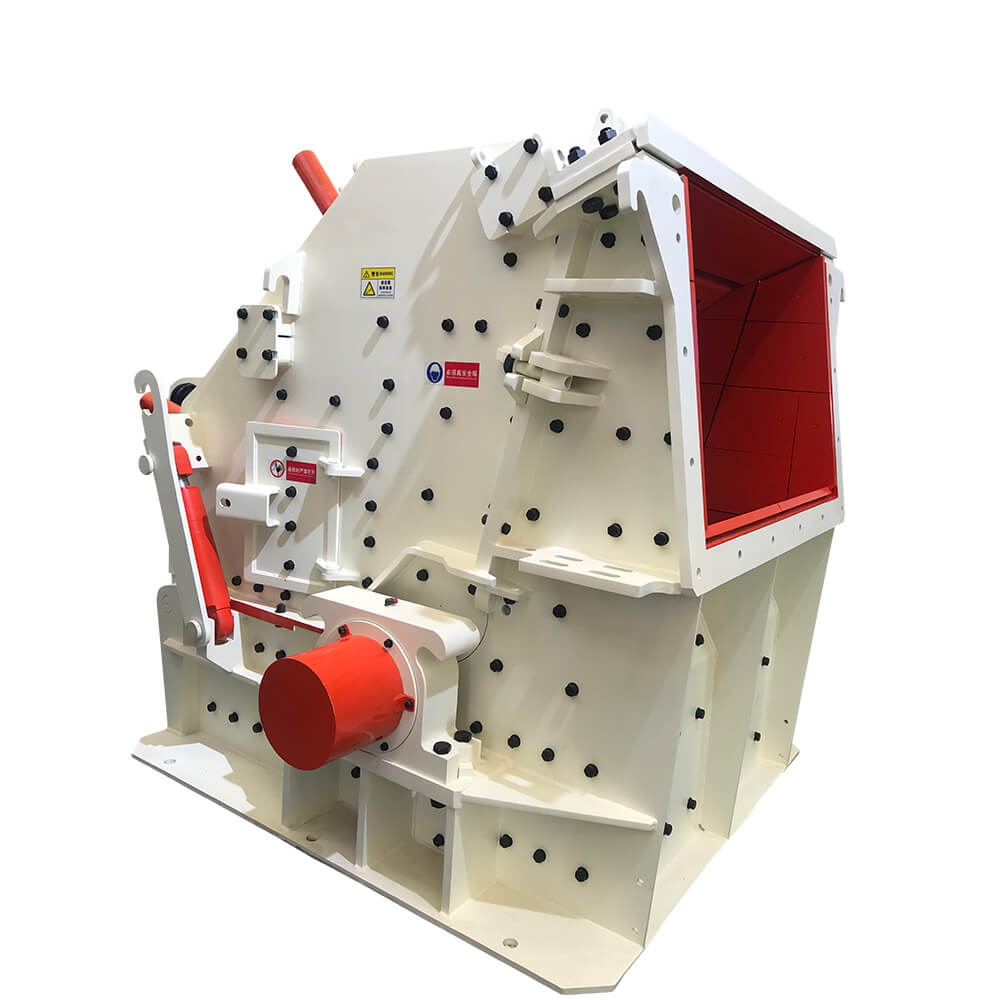

2. Efficient crushing

The crusher is the core of complete crushing platn, jaw crusher, impact crusher, cone crusher are very popular.

3. Multilayer screening

vibrating screen can screen and grade the crushed materials into different piles.

4. On-board conveyer

Belt conveyor is the important auxiliary equipment which is connect rock crusher, feeder, final product piles, etc.

Easily transportable mobile crusher

★Mobile Jaw Crusher

There’s a sturdy tracked mobile jaw crusher with capability ranging from 70 – 300 tons to meet your specific requirements.

★Mobile Impact Crusher

The mobile horizontal shaft impact crusher generally used in the primary, secondary or tertiary stage of crushing process, produce cubic shape aggregate forconstruction.

★Mobile Cone Crusher

Our range of mobile cone crushers meet any size reduction challenge in secondary and tertiary crushing process, provide you with high quality materials and good shape. If the particle size of the processed material is small enough, they can also be operated as the primary crusher.

technical specifications

| Portable Jaw Crusher | ||||||

| Model | Vibrating grizzly feeder | Jaw Crusher | Belt machine Specification | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| DN938P69 | DN380×95 | PE600×900 | B800×8M | 70-150 | 91.5 | 13200×2900×4700 |

| DN1142P710 | DN420×110 | PE750×1060 | B1000×11M | 90-200 | 134 | 15000×3100×5100 |

| DN1349P129 | DN490×130 | PE900×1200 | B1200×13M | 150-300 | 146 | 17000×3300×5600 |

| Portable Impact Crusher | ||||||

| Model | Circle Vibrating screen | Impact Crusher | Belt machine Specification | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| 3YD1848F1210 | 3YD1848 | PF-1210 | B650×7M | 70-300 | 128.5-150.5 | 12500×3000×6500 |

| 3YD1860F1214 | 3YD1860 | PF-1214 | B650×8M | 90-400 | 154-190 | 13500×3000×6500 |

| 3YD2160F1315 | 3YD2160 | PF-1315 | B800×8M | 120-450 | 210-297 | 14000×3200×6800 |

| Portable Cone Crusher | ||||||

| Model | Circle Vibrating screen | Cone crusher model | Belt machine Specification | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| 3YD1848DN10SX | 3YD1848 | DN1000S-X | B650×7M | 70-300 | 99-134 | 13000×3000×6700 |

| 3YD1860DN12SX | 3YD1860 | DN1200S-X | B650×8M | 120-400 | 212.5-220.5 | 14000×3000×6700 |

| 3YD2160HP200 | 3YD2160 | HP200 | B800×8M | 140-450 | 257.5-264.5 | 14000×3200×6700 |