grinding ball mills for sale

Our site mainly provide the most common used ball mill, with a wide range types and capcities.

ball mill

1-95 TPH industry ball mills

Eastman ball mill have a wide range of models to choose from, form Ø 900*1800 to Ø 3200*4500, you can find almost every size of ball mill machines you need

grinding stage

Typically and at sometimes, grinding stages are followed after crushing stages because the materials need to be further reduced.

The grinding stage use the material after the crushing stages to achive a finer output material. Crushers are used to reduce particle size enough so that the material can be processed into finer particles like powders in a grinder.

So, a typical processing line at a mine might consist of a crusher followed by a SAG mill or a ball mill. In this context, grinding mills like ball mills are considered grinders rather than crushers.

applications

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes, like the mineral processing. There are many different types of mills and many types of materials can be processed in them.

Our Eastman ball mill is mainly used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed.

For systems with multiple components, our ball milling has been shown to be effective in increasing solid-state chemical reactivity. Additionally, it has been shown effective for production of amorphous materials. all those data are test from our lab

working

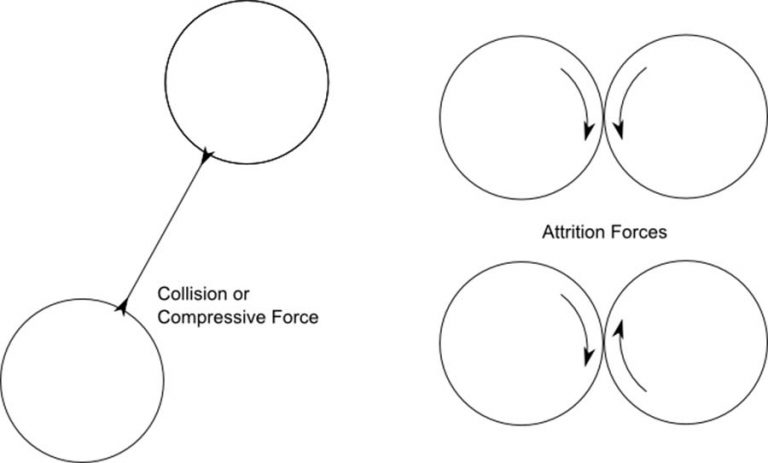

In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30° cone to the right. As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell. In doing so, the solid particles in between the balls and ground are reduced in size by impact.

grinding media

We also have fine quality grinding media for sale, if you need more detail about our grinding steel balls, please direct contact us at here.

There are 5 key properties of grinding and milling media: size, density, hardness, composition and the cost.

- Initial and final particle sizes of the materials

The size of milling media should be selected based on the material. Multiple milling steps using different size milling media may be needed to achieve the best milling effect. It is also possible to use a combination of milling media sizes in a single milling process to achieve desired final particle size.

- Density

Milling media with higher density usually have better milling efficiency and can lead to smaller final particle size of the material to be ground. The media should have higher specific gravity than the material to be milled.

- Hardness

Harder media have higher wear resistance, less contamination, and better milling efficiency.

- Composition

The selection of media composition depends on the compatibility with the material to be milled, and the container and liner materials used in the milling process. The goal is to minimize contamination and yet to achieve the best milling effect.

- Cost

Tungsten carbide and zirconia milling media typically have higher cost than alumina and agate milling media, however, they are also more wear resistant and provide better milling efficiency, and therefore, the actual milling operation costs can be lower even though the milling media cost is higher.

Frequently Asked Questions

How many types of grinding mills?

1. According to the discharging method, the ball mills divided into grid type and overflow type.

2. According to the shape of the barrel, divided into short cylinder ball mill, long barrel ball mill, tube mill and cone mill.

3. According to the grinding media, divide into steel ball mill, rod mill.

4. According to the moisture content, divide into wet type ball mill, dry ball mill.

what are the Popular models of ball mill?

| Model | Sheel rotation speed (r/m) | Ball load(t) | Feeding size(mm) | Capacity (t/h) | Weight (t) |

| Ф1830×4500 | 25.4 | 15 | <25 | 4.5-12 | 38 |

| Ф2100×4500 | 23.7 | 24 | <25 | 8-43 | 56 |

| Ф2200×7500 | 21.7 | 35 | <25 | 15-30 | 64.8 |

| Ф5500×8500 | 13.8 | 338 | <25 | 148-615 | 525 |

which ball mill is suited for 100-300TPD limestone plant?

Most crushing plant on-site working time is 8-10 hours, then the output of the ball mill per hour is required to 10-37.5 TPH. The ball mill models that meet this standard are Ф2100 × 3000, Ф2100 × 4500, Ф2200 × 4500.

What are the small cement ball mills?

Small cement ball mill is a general name for the low capacity cement ball mill models, commonly used are Ф900 × 3000, Ф1200 × 4500, Ф1500 × 3000, Ф1830 × 3000, Ф1830 × 4500.

How long is the service life of wearing parts?

The wearing parts of our company’s equipment are all made of high wear-resistant materials. The cylinder, liner, grinding medium, partition board and discharge grate are made of high-quality original components, which are durable and have a double longer life than ordinary wear parts, please call for a discussion.

Can you deliver the goods on time?

Eastman is a typical direct selling enterprise with green and standardized production plants. All the delivery of the equipment will be completed within the delivery period signed by the contract to ensure the smooth commissioning of the equipment.