mobile crushers for sale

Eastman provides those track-mounted or wheel-mounted rock crushing machines that are easily movable on and deploy between production sites.

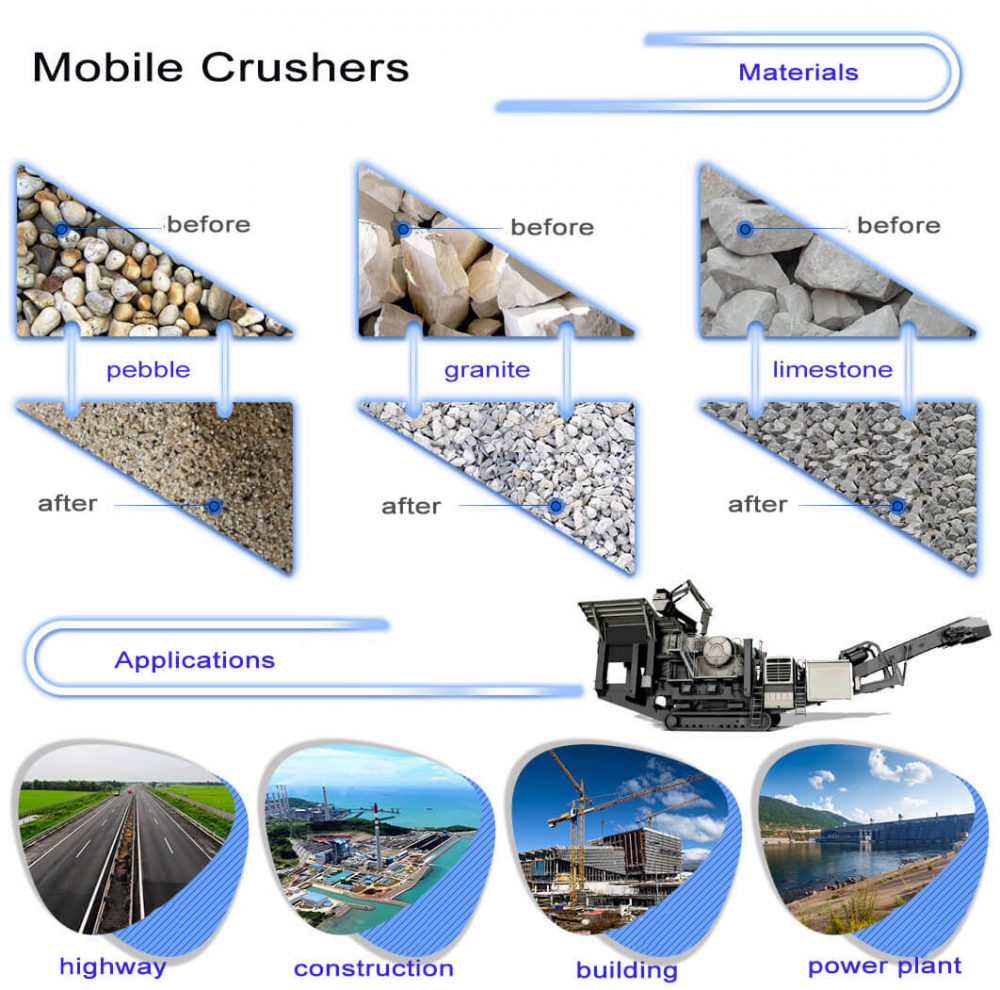

Those machines are widely used in aggregates production, mining operations, or in some recycling applications.

mobile crusher advantages

Mobile crusher is often referred to as ‘mobile crushing plant’, is a wheel or crawler rock crushing plant that innovatively designed for unfixed production sites, it easily movable in a varieties of rock crusher applications like aggregate production, construction waste recycling, quarrying, mining industry.

The greatest advantage of mobile crushers is the flexibility, both tracked and wheeled versions, greatly shoot the trouble of hauling and thus maximise productivity reduces the operation costs.

In fact, the concept of mobile and semi-mobile crushing plants has arouse for a long time, but it has not been realized until recent years, mainly because most machines are very heavy, it is not easy to move them. Therefore, most crushers are permanent facilities and rarely relocated. Now, the mobile crusher can replace the stationary crushing system.

- Flexible capacity and reliability

Designed and engineered with more than a century of crushing experience. Premium components and persistent quality testing.

- Energy-saving and environment friendly

Easy to transport. Electric drive. Advanced dust and noise reduction.

- Operation Safety

The process starts and stops by pressing one button. Proper stairs and platforms. Finger protection and safety wires.

- Easy to use and maintain

Real-time diagnostics and process optimization. Simple to maintain. Comprehensive service network to support.

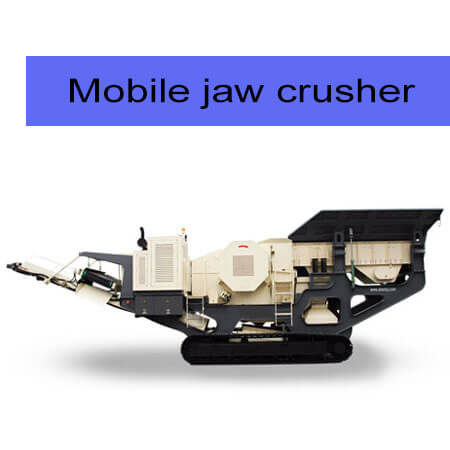

Mobile jaw crusher

If you’re looking for a heavy duty primary crushers rugged using in heavy mining, recycling and quarried materials, the mobile jaw crushers are right for these tough operations to reduce the material to smaller sized for further processing. There’s a sturdy tracked mobile jaw crusher with capability ranging from 50 – 450 tons to meet your specific requirements.

Features: Remote control to clear the blockage and adjust jaw gap, automatic iron removal. It is ideal for quarrying and the like industries.

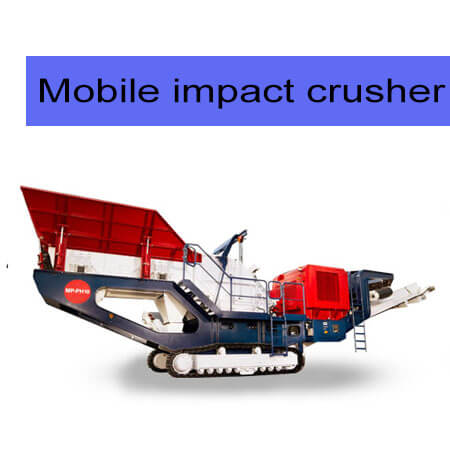

Mobile impact crusher

Mobile impact crushers are divided into two categories: mobile horizontal shaft impactor (HSI) and mobile vertical shaft impactor (VSI).

The mobile horizontal shaft impact crusher generally used in the primary, secondary or tertiary stage of crushing process. Mobile VSI crusher, or called as mobile sand making machine, is equipped with vertical shaft impact crushing device, usually used in fine crushing and particle shaping process, can produce more uniform cubic end products desirable in the aggregate industry.

Mobile cone crusher

Our range of mobile cone crushers meet any size reduction challenge in secondary and tertiary crushing process, provide you with high quality materials and good shape. If the particle size of the processed material is small enough, they can also be operated as the primary crusher.

Our hydraulic cone crushers are versatile & intelligent, with a compact design, minimal manual operation, wide range of chamber options and eccentric throw adjustments, making this cone crusher plant one of the most trusted cone crusher in applications.

FAQ

- Option 1. High-hardness rock crushing ($100,000-180,000)

Main equipment: jaw crusher, HP hydraulic cone crusher, 2YK1548 vibrating screen

Applicable materials: iron ore, granite, basalt, quartz, etc.

Production capacity: 80-200t / h

Feeding granularity: ≤500mm

The discharge can meet the requirements: 10-30mm - Option 2. Medium hardness rock crushing ($70,000-150,000)

Main equipment: jaw crusher, PF1210 impact crusher, 2YK1548 vibrating screen

Applicable materials: limestone, granite, gypsum, marble, coal gangue, construction waste, etc.

Production capacity: 70-130t / h

Feeding granularity: ≤500mm

The discharge can meet the requirements: 10-30mm - Option 3. Small stone fine crushing ($600,000 -100,000)

Main crushing machine: 1200 * 1200 fine crusher

Applicable materials: limestone, cement block, coal gangue, quartz sand, etc.,

Production capacity: 10-110t / h

Feeding granularity: ≤120mm

The discharge can meet the requirements: 10-30mm

Advantages: it can process materials with a moisture content of about 8% without clogging. With a multi-layer vibrating screen, produce two kinds of discharge particles. - Contact engineer to design process flow, select the right machine.

Mobile construction waste crusher can sort, remove iron, crush, and screen various construction waste (waste concrete, bricks, slag, etc.), and produce finished aggregates of various sizes.

After being crushed, construction waste can be used to produce environmentally friendly bricks, non-fired bricks, waterproof bricks, etc., which greatly improves the utilization rate of construction waste and truly realizes resources recycling. Get a price!

The complete equipment of the mobile crusher is mainly composed of feeder, crusher, vibrating screen, conveyor, frame, tires, power distribution cabinet, etc.

Yes, of course, and it’s complete free of charge.

Eastman service: Quality guarantee; Timely delivery; Free design; Installation, debugging, operation training. If you have other questions, just let me know.