350-400TPH Granite Sand Making & Washing Plant

Material: Granite

Capacity: 350-400TPH

Output size: 0-5mm

Input Size: 0-780mm

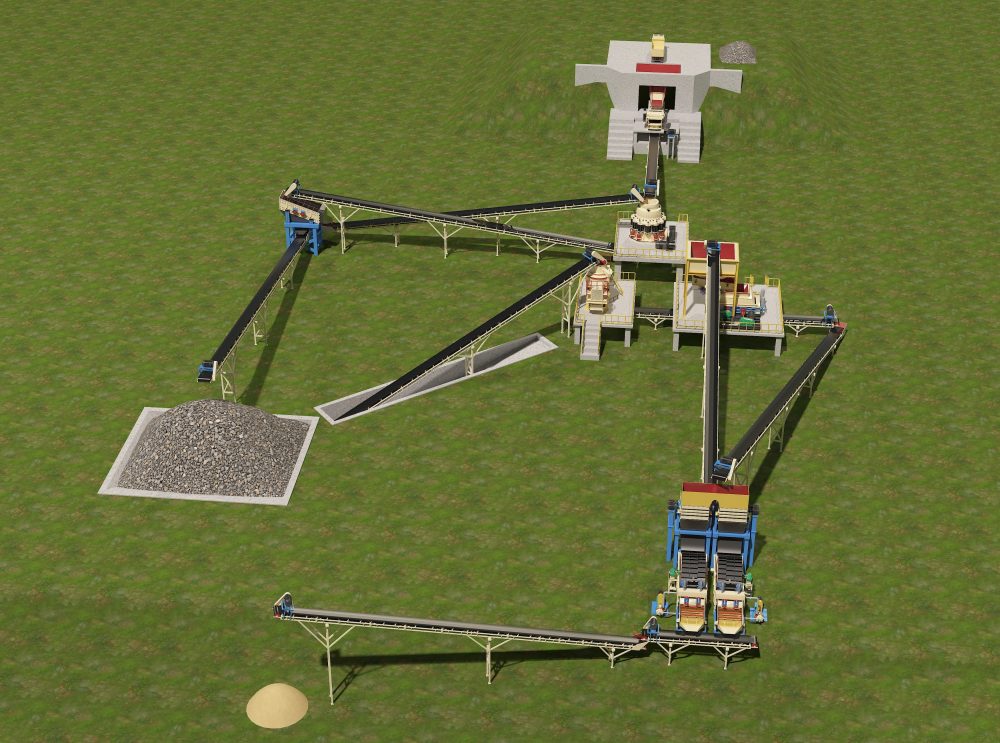

Schematic Diagram of Process Equipment

Equipment Used

- Hopper

- Vibrating feeder DN6013

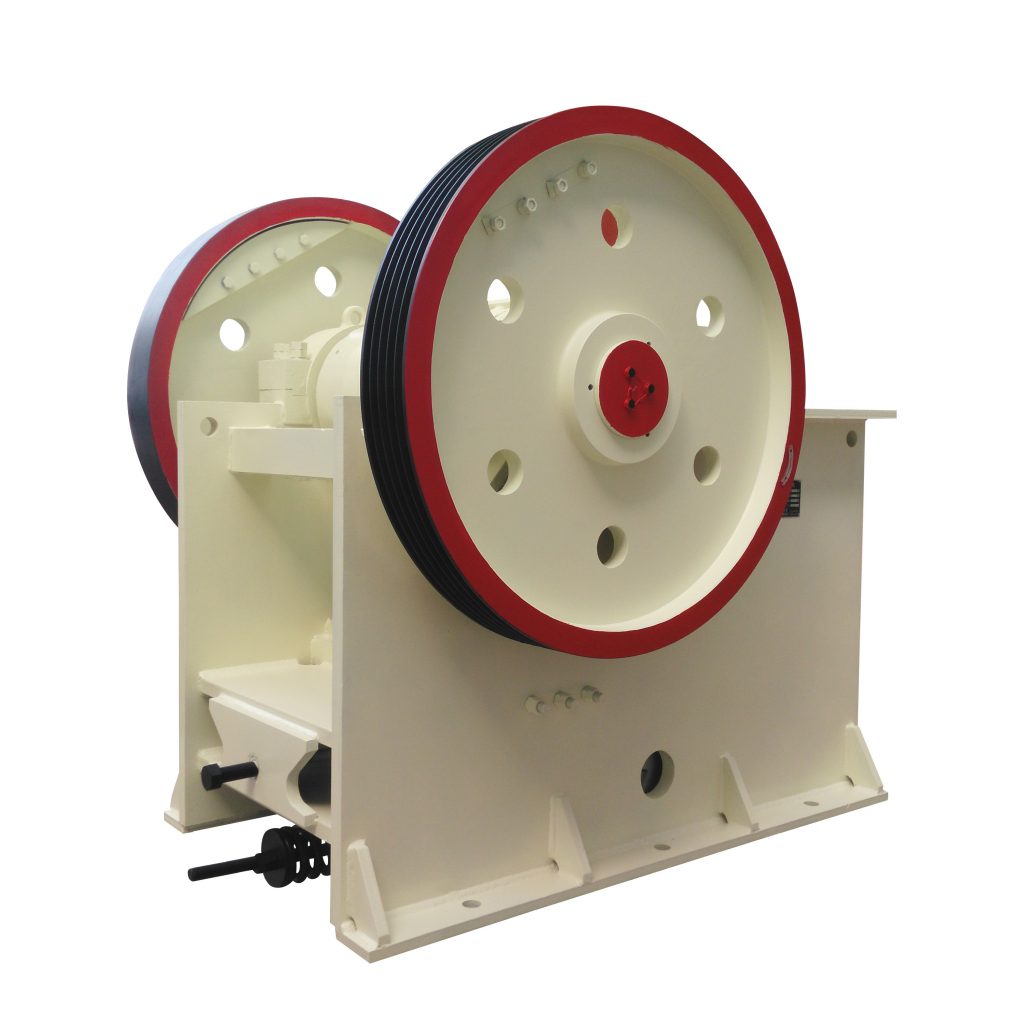

- Primary jaw crusher PE-900*1200

- Cone crusher DN1650

- Vibrating screen 2YD2470( 2 sets)

- VSI DN10000

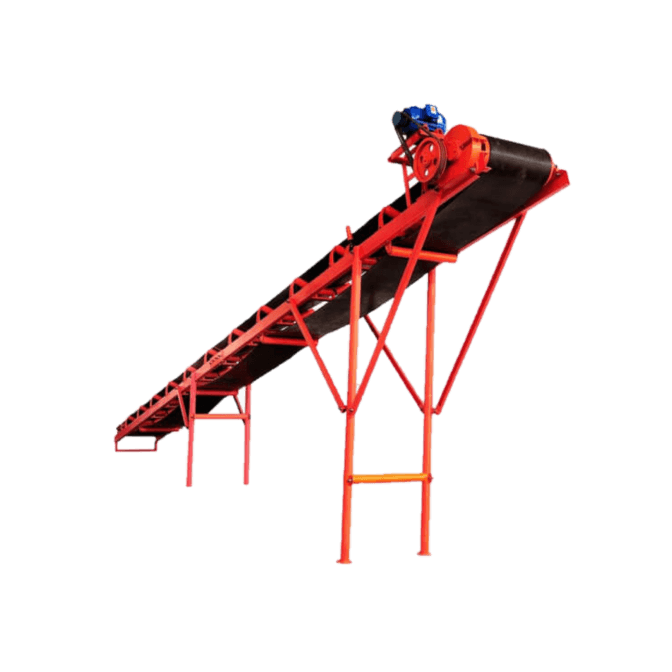

- Belt conveyors

Flow Description

- The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper;

- The vibrating feeder feeds the stones evenly to the primary jaw crusher;

- The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher by a belt conveyor;

- The crushed output materials from the secondary cone crusher will be transported to the two-layer vibrating screen;

- After screening by the two-layer vibrating screen, will get 0-35mm and +35mm materials. 0-35mm materials will be transported out by a belt conveyor to stockpile, +35 materials will be transported back to the cone crusher for re-crushing.

- 0-35mm materials in the stockpile will be fed to the conveyor belt by a vibrating feeder. Then it will be transported to the VSI crusher to be crushed and shaped. the output materials will be transported to the second and third vibrating screen;

- After the screening, will get 0-5mm materials, the +5 mm materials will be transported back to double roller crushers. The advantage of double roller crushers is less dust and a relatively high sand output rate.

- 0-5mm material will be washed by two sets of wheel sand washers, it can be a spiral type sand washer.

- The output of the sand washer will be dewatered by the fine sand recycling machine DN2045.

Supplement:

- The role of the VSI crusher in this setup for producing high standard output materials for mixing stations, asphalt stations, etc.

- This crushing plant is suitable for processing many kinds of hard stones, like basalt, pebbles, granite, diabase, etc.

- The capacity for this crushing plant can be customized as per request such as 200tph, 300-400tph,1000tph, etc.

Our Advantages

➤Professional Engineers Team

Tell us raw material of your aggregate plant, input size, output size, and capacity. Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you. Also, our engineers can design the flowchart according to your needs. Answer any aggregate questions for you.

➤Excellent Crusher Manufacturers

Our company was founded in 1985. In the aggregate crushing industries, we have 35+ years of machinery production of experience. All the equipment of stationary crusher plant, mobile(portable) crusher plant are choose the best materials, and meticulously casting every part. High Performance & Ease of Operation, many crushers equipment in stock.

➤Good Service

We have a office in Tanzania.The customers of regions near Tanzania and Tanzania, we provide installation service for free. All of our equipment, 1 Year Warranty.