hP Cone Crusher

[Capacity] 70-1200t/h

[Feed size] <320mm

[Output size] 5-40mm

Capacity

1-1120t/h

Output size

10-350mm

Capacity

70-1200t/h

Output size

5-40mm

HP cone crusher widely used in the quarrying, mining, aggregate processing, construction waste recycling applications. Thanks to its optimized, efficient and relibale performance, HP cone crusher has been the most popular cone crusher in the world.

Applications

mining, quarry, aggregate making, etc.

Materials

River pebbles, limestone, dolomite, granite, diabase, basalt, rhyolite, ferrous metal ore, nonferrous metal ore, construction waste, coal gangue, tailings, etc.

Hot sale models

HP200

Capacity: 72-250t/h

Feed size: 178mm

Discharge: 8-38mm

HP400

Capacity: 104-630t/h

Feed size: 68-280mm

Discharge: 8-51mm

Hot Sale

HP 200

Capacity: 72-250t/h

Feed size: 178mm

Output: 8-38mm

HP 400

Capacity: 104-630t/h

Feed size: 68-280mm

Output: 8-51mm

HP 800

Capacity: 166-1100t/h

Feed size: 77-326mm

Output: 8-51mm

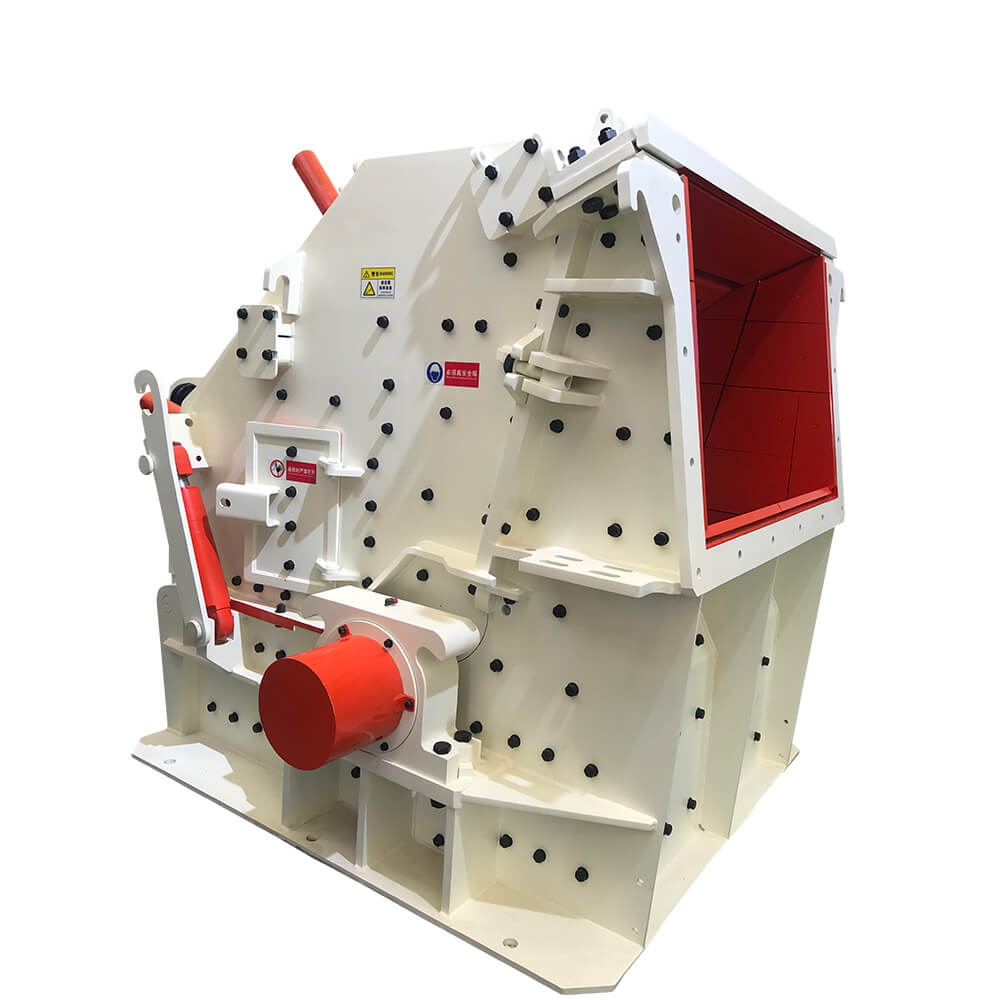

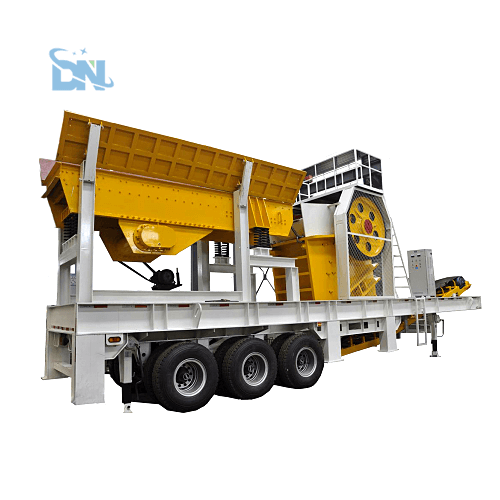

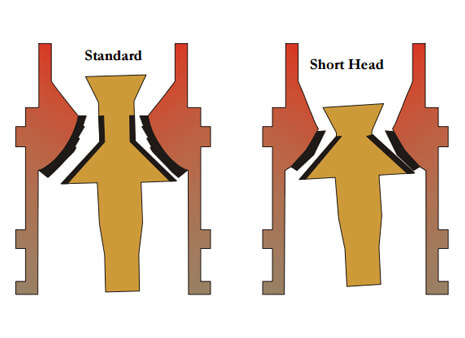

Eastman cone crusher families

Short head & standard head

We offers types of cone crushers to meet different requirements of discharge size, shape.

HP, GP, Symons Cone Crusher

Select the rightest cone crushers to maximize your profit. Effect crushing with the lowest maintain.

Stationary, mobile version

stationery cone crusher and portable cone crusher (wheel or crawler) to meet the toughest demands of crushing applications.

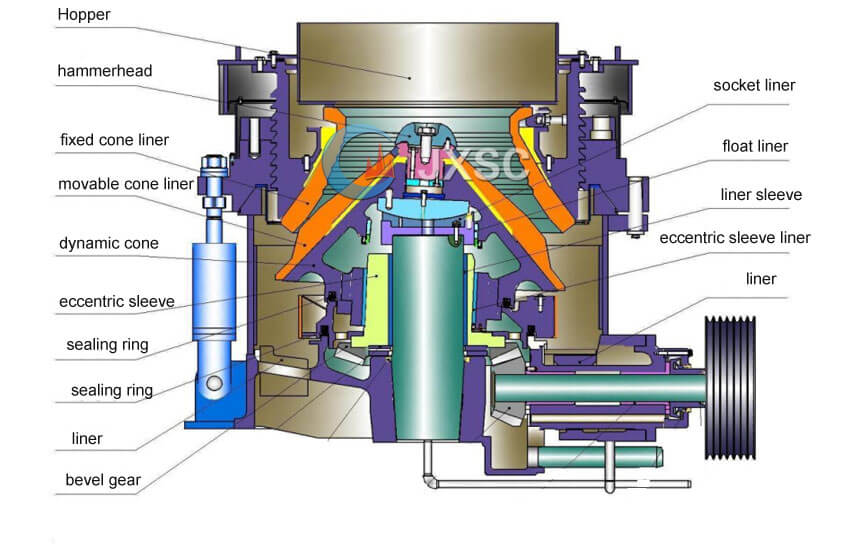

Cone crusher working principle

Cone crushers are suitable for all demanding crushing needs

- Structure upgrade, more efficient

On the basis of the unique spindle fixed and eccentric sleeve rotating around the spindle, further optimize the design of transmission parts and lubricating seal structure, the equipment has strong bearing capacity, small size, high efficiency and low noise. - Cost efficient and ecological

By ensuring that the internal pressure of the crushing chamber is always higher than the external pressure, it effectively reduces the dust or other small particles entering the crusher, reduces the damage to the bearing, thus reducing the maintenance workload, prolongs the service life of the lubricating oil and equipment, and facilitates the maintenance. - Good cubic shape

Optimizated cavity improves the lamination crushing efficiency, reduce wear, the finished product grain shape is cubic, with higher fine grain product.

- Hydraulic control, safe and friendly

From cavity cleaning to adjustment, all adopt hydraulic automation operation, precise adjustment and control of discharging, rapid response self-protection when there is blockage. - Hydraulic & Lubrication integration

The integrated hydraulic lubrication system and centralized automatic intelligent control system save the cost of hydraulic lubrication input, and at the same time monitor the running status of the equipment in real time to ensure the safe and stable operation of the equipment. - Multicavity conversion

It is equipped with many medium crushing and fine crushing cavity types, only need to replace the corresponding cavity type lining board and a small number of parts, it can be converted into different cavity types, better meet the needs of medium crushing and fine crushing process, to achieve a multi-purpose machine.

technical specifications

| Model | Cavity | Standard Type | Short Type | Power(kw) | Capacity (t/h) | ||

| Feeding Size (mm) | Min Discharging Size (mm) | Feeding Size (mm) | Min Discharging Size (mm) | ||||

| HP200 | Super coarse | 132-200 | 90-250 | ||||

| Coarse | 185 | 19 | 76 | 10 | |||

| Medium | 125 | 17 | 54 | 6 | |||

| Fine | 95 | 13 | 23 | 6 | |||

| Super Fine | 10 | 5 | |||||

| HP300 | Super coarse | 230 | 25 | 180-250 | 115-440 | ||

| Coarse | 210 | 20 | 75 | 10 | |||

| Medium | 150 | 15 | 50 | 8 | |||

| Fine | 105 | 10 | 20 | 6 | |||

| Super Fine | 20 | 6 | |||||

| HP400 | Super coarse | 295 | 30 | 280-355 | 140-630 | ||

| Coarse | 250 | 25 | 90 | 10 | |||

| Medium | 195 | 20 | 50 | 8 | |||

| Fine | 110 | 14 | 40 | 6 | |||

| Super Fine | 30 | 6 | |||||

| HP500 | Super coarse | 330 | 30 | 355-450 | 175-790 | ||

| Coarse | 285 | 25 | 90 | 13 | |||

| Medium | 200 | 20 | 55 | 10 | |||

| Fine | 133 | 16 | 40 | 8 | |||

| Super Fine | 35 | 6 | |||||

| HP800 | Super coarse | 353 | 32 | 550-630 | 260-1200 | ||

| Coarse | 297 | 32 | 155 | 13 | |||

| Medium | 267 | 25 | 92 | 10 | |||

| Fine | 219 | 16 | 33 | 6 | |||

| Super Fine | |||||||

maintenance and parts

HP cone crusher, also known as Multi-cylinder hydraulic cone crusher, it is a high production level cone crusher developed in China in combination with the actual production situation of the domestic market.

With higher speed and stroke, improve the crusher’s passing ability, crushing ability. Both crushing efficiency and discharging shape & particle are optimized and upgraded, which are widely used in the medium, fine and ultra-fine crushing operations of granite, basalt and other rocks above medium hard, and are commonly used in large stone factories, mineral processing production and other fields.

Eastman provides complete perfect fit original cone crusher parts.

1. Movable cone

It is forged from new composite high manganese steel, which has the characteristics of super wear resistance, high cost performance and wide application fields. Newly installed movable cone, after working for 6~8 hours, check its fastening condition, and tighten immediately if loose.

2. Fixed cone

The fixed cone and the movable cone are the main parts of crushing materials in cone crusher.

3. Bearing Bowl type bearing

4. Sliding bearing

5. Lining plate

6. Feed distributor