500tph Quartz Sand Making Plant

Capacity: 700t/h

Material: quartz sand

Equipment: Vibrating feeder, jaw crusher, sand making machine,

circular vibrating screen, sand washing machine, belt conveyor, etc

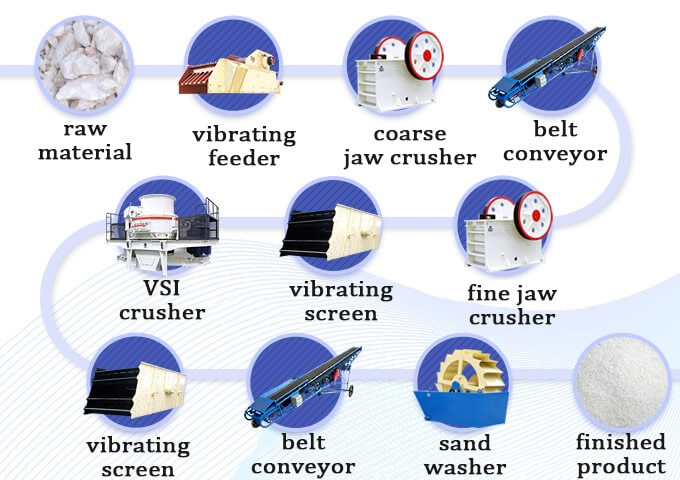

process flow

❶Crushing: Raw quartz ore is continuously fed into the coarse jaw crusher by the vibrating feeder for primary crushing processing, and then into the fine jaw crusher via the conveyor for re-crushing.

❷Sand making: The circular vibrating screen screens the quartz sand after jaw crushing, and the quartz sand particles that meet the feed size requirements of the sand making machine enter the sand making stage, and the oversized materials are returned to the crusher to be crushed again.

❸Screening: The quartz sand particles discharged from the sand making machine are screened by circular vibrating screen again.

❹Washing: The quartz made into fine particle sand is sent to the sand washing machine by the conveyor for cleaning, and the finished product is obtained.

on-site

Eastman learned about the client’s production and processing requirements, and then analyzed the characteristics of the quartz sand in the customer area and the on-site situation, and designed this quartz sand production line with an output of 500t/h.

performance

▶Reasonable production line design and good stability, wear-resistant parts.

▶The failure rate, total energy consumption and ultra-low power consumption during operation are all low, and operating costs can be reduced by more than 50%.

▶Equipped with a pulse dust collector, there will be no dust pollution problems during operation, and the low-carbon environmental protection effect is more significant.

▶Good after-sales service.

Products Recommended

Jaw crusher

Vibrating feeder

VSI crusher

sand washer

select for you

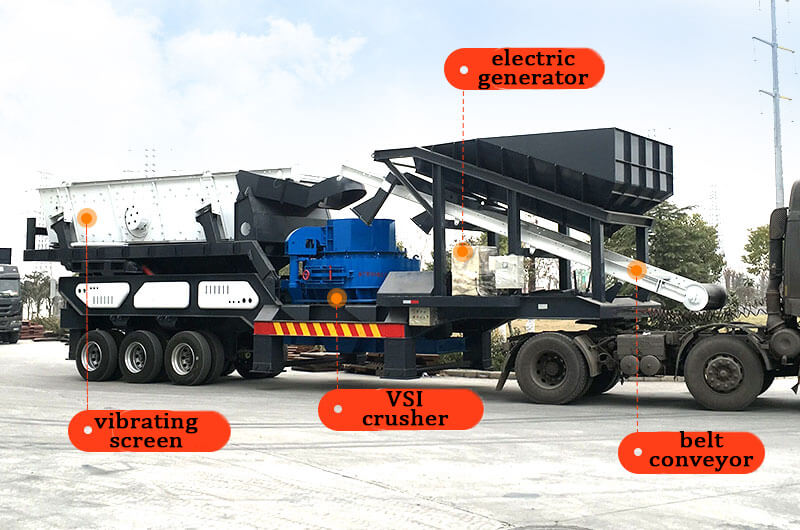

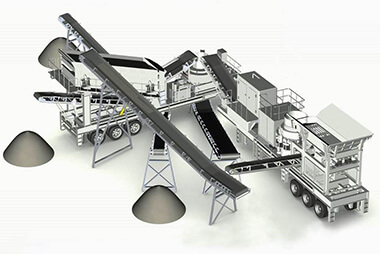

The mobile sand making machine is composed of crushing, screening, conveying, and power control system, and can be divided into a tire-type mobile sand making machine and a crawler-type mobile sand making machine.

It is very suitable for unfixed production sites or small working space, flexible transition and convenient operation, which can save a lot of transportation costs.

services

Happy Customers

Quick quotation, free crushing flow design, on-site service! Respond to you within 24 hours.