conveyor belt

[Capacity] 1-1030t/h

[Max length] 30mm

[Power] 5.5-22Kw

Capacity

0-1030t/h

Max Length

30m

Conveyor belt is the link equipment connecting crusher, feeder, screen, and so on equipment, to achieve the continuity and automation of production, improve productivity and reduce labor intensity.

Applications

transportation and production lines in cement, mining, metallurgy, chemical, foundry, building materials and other industries, as well as production sites such as hydropower stations and ports.

Material

all kinds of soft and medium hard ore, construction waste, tailings, steel slag.

Eastman conveyor belt

Customizable multi layers

can be either single conveying, or multiple layers, horizontal or inclined conveying versions.

Variable frequency motor

adjust the speed, easy to control the amount of feed, don’t need to restart.

Wide applicability

can be used in the range of ambient temperature from -20℃ to +40℃, and the temperature of conveying materials is below 50℃.

High quality rubber belt

Customizable length, thickness and width, high quality rubber belt with good load bearing performance.

conveyor belt working principle

- First, the weight of the passing material is measured by a weighing scale to determine the weight of the material on the belt, so that the digital speed sensor mounted on the tail continuously measures the running speed of the feeder, and the pulse output of the speed sensor is proportional toThe speed of the feeder;

- the speed signal and the weight signal are sent to the feeder controller, and the microprocessor in the controller processes it to generate and display the cumulative amount / instantaneous flow.

The flow is compared with the set flow, and the belt conveyor is controlled by the output signal of the control instrument to achieve the requirements of quantitative feeding.

the belt conveyor used in industries area

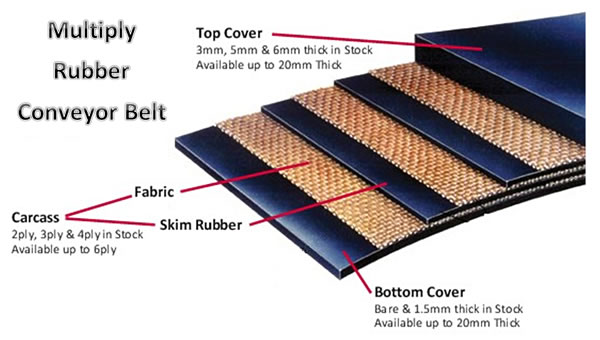

structure & parts

Top cover

–Various compounds choices

–Excellent carry side performance

–Anti impact, anti abrasion, and anti tearing.

Piles

–Excellent tensile strength in both longitude and latitude directions

–Much lighter in weight comparing with steel and solid woven textile belts

–Provides excellent troughability

–Excellent flexbility

Rubber between piles

–Provides superior adhesion between piles

–Prevents piles from separation

–Provides improved splice efficiency

Bottom cover

–Various compounds choices

–Excellent running side performance

–Anti abrasion, anti tearing

conveyor belt Technical specifications

| Model | Capacity (t/h) | Max length (m) | Belt width (mm) | Speed (m/s) | Upper slope (°) | Power (kw) | Drum dia (mm) | Roller Dia (mm) |

| DT75-500 | 87 | 20 | 500 | 1 | <20 | 5.5 | 500 | 89 |

| DT75-650 | 127 | 20 | 650 | 1 | <20 | 7.5 | 500 | 89 |

| DT75-800 | 198 | 15 | 800 | 1 | <20 | 7.5 | 630 | 89 |

| DT75-1000 | 507 | 20 | 1000 | 1.25 | <20 | 11 | 800 | 108 |

| DT75-1200 | 742 | 20 | 1200 | 1.25 | <20 | 15 | 1000 | 108 |

| DT75-1400 | 1032 | 30 | 1400 | 1.25 | <20 | 22 | 1000 | 133 |

Solutions & cases

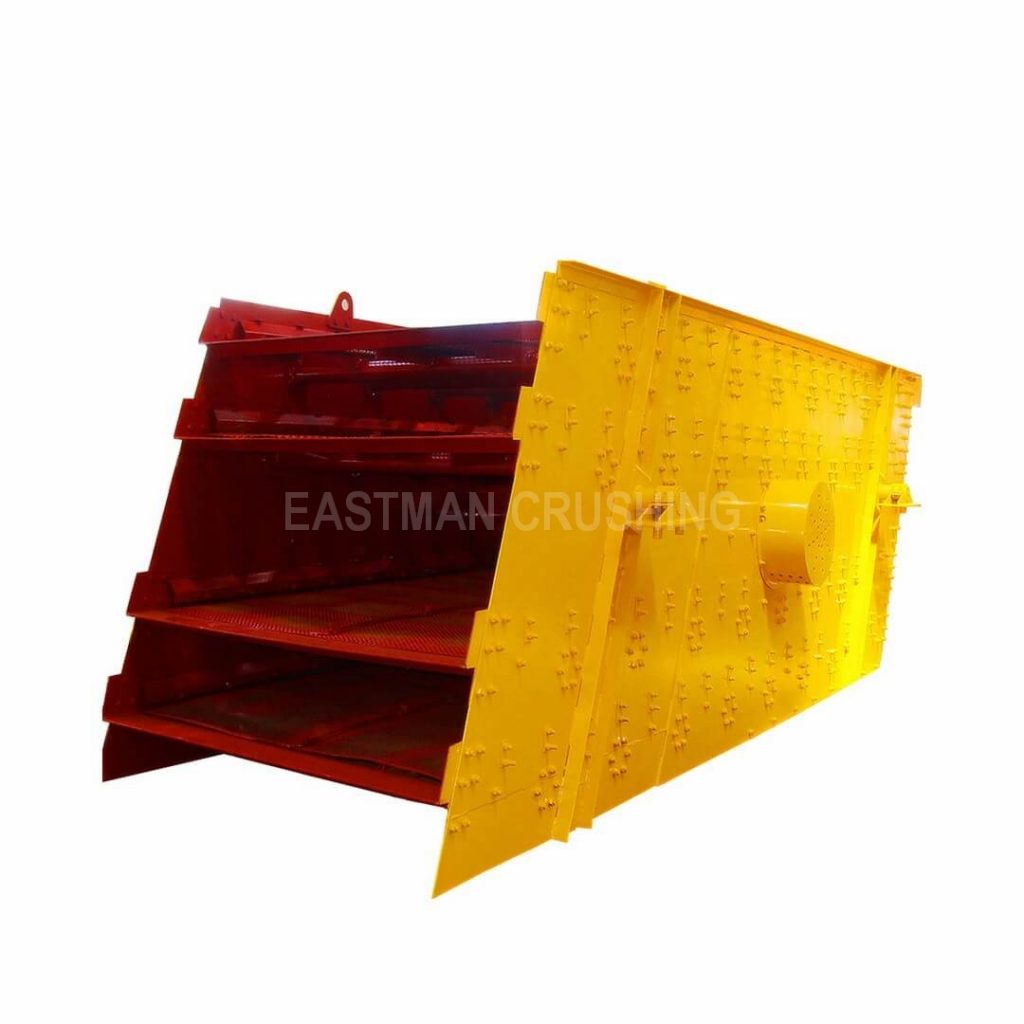

Related products

Hydraulic Cone Crusher

the most intelligent cone crusher

Primary Jaw Crusher

the most popular primary crusher

Ball Mill

effect crushing & grinding circuit

Customizable layer and mesh

design as you need