vibrating feeder

[Capacity] 1-1120t/h

[Feed size] <1000mm

Capacity

1-1120t/h

Output size

10-350mm

Capacity

30-1200t/h

Feed Size

<1000mm

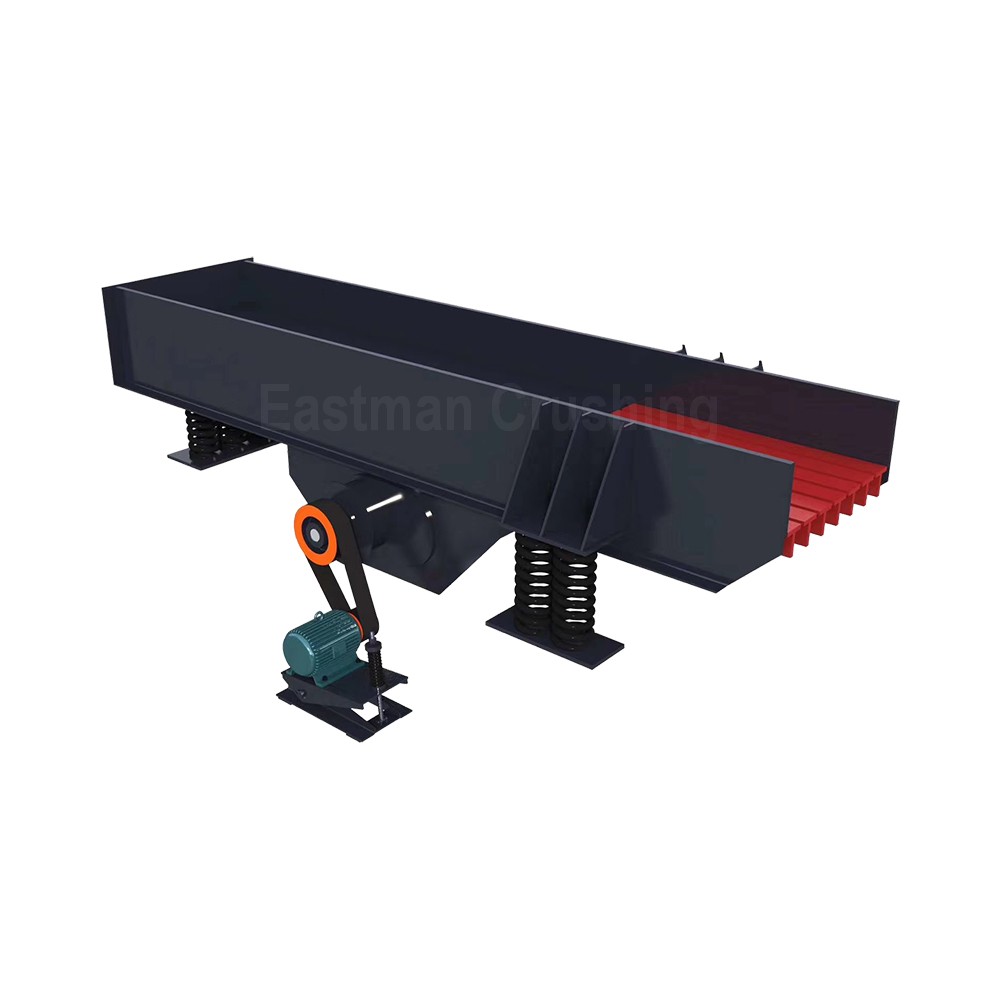

Vibrating screen is mainly used for continuous and uniform feeding in front of the coarse crushing crusher, and at the same time, it can screen fine materials to increase the crusher processing capacity.

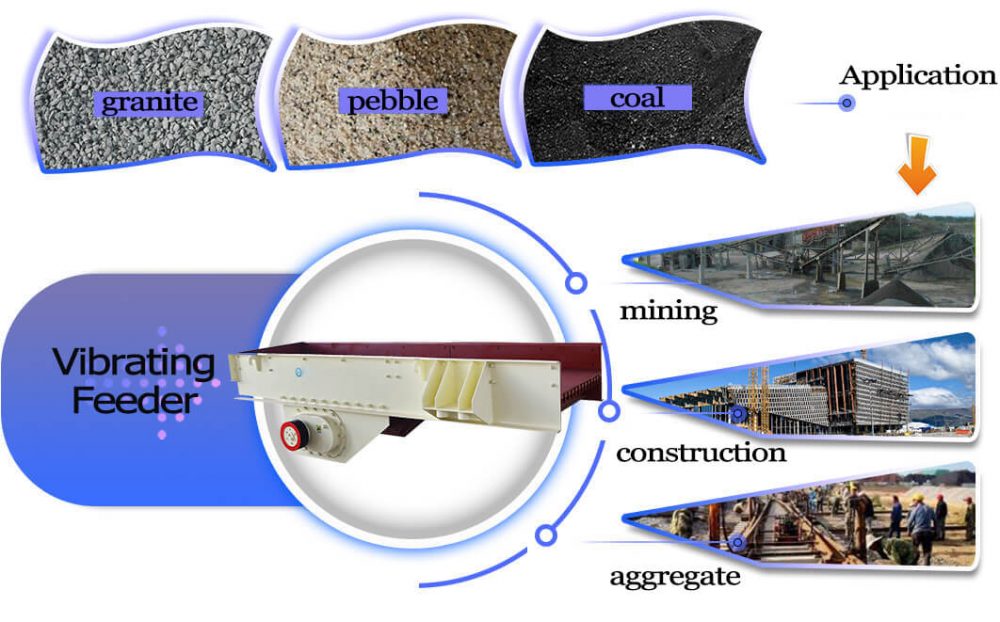

Applications

in the crushing and screening equipment of metallurgy, coal mines, beneficiation, building materials, chemicals, abrasives and other industries.

Material

River pebbles, granite, basalt, iron ore, limestone, quartz, coal, gangue, construction waste, etc.

Eastman vibrating feeder

Convey coarse, fine materials

Bulk, grain, powder and other materials of different forms can be transported

Variable frequency motor

adjust the frequency, easy to control the amount of feed, don’t need to restart.

Rubber isolation spring

longer service life, little noise, stable resonance region.

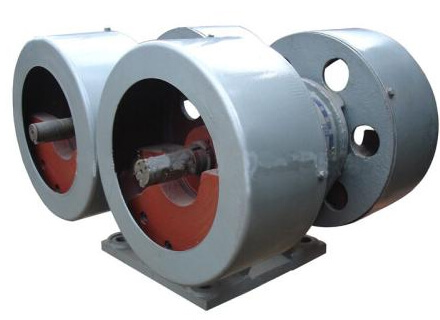

Eccentric shaft vibration exciter

Double eccentric shaft, stable performance, adjustable dxcitation force.

vibrating feeder working principle

vibrating feeder in industry

Technical specifications

| Vibrating feeder parameter | ||||||

| Model | Funnel Size (mm×mm) | Input size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) | Dimensions (mm) |

| GZD-800×3000 | 800×3000 | 400 | 80-120 | 2.2 | 3195 | 3110×1800×1600 |

| GZD-960×3800 | 960×3800 | 500 | 120-210 | 2.2×2 | 3375 | 3850×1950×1630 |

| GZD-1100×4200 | 1100×4200 | 580 | 200-430 | 3.7×2 | 4400 | 4400×2050×1660 |

| GZD-1100×4900 | 1100×4900 | 580 | 280-500 | 5.5×2 | 4675 | 5200×2050×1700 |

| GZD-1300×5200 | 1300×5200 | 650 | 450-600 | 7.5×2 | 5400 | 5200×2350×1750 |

| ZSW-950×3800 | 950×3800 | 500 | 96-160 | 11 | 4100 | 3882×2224×2121 |

| ZSW-1100×4200 | 1100×4200 | 580 | 120-240 | 15 | 4745 | 4310×2500×1365 |

| ZSW-1100×4900 | 1100×4900 | 580 | 120-280 | 15 | 5420 | 4957×2500×1365 |

| ZSW-1100×5900 | 1100×5900 | 630 | 160-350 | 22 | 6100 | 6000×2500×2150 |

| ZSW-1300×5900 | 1300×5900 | 630 | 250-400 | 37 | 6300 | 6000×2700×2150 |

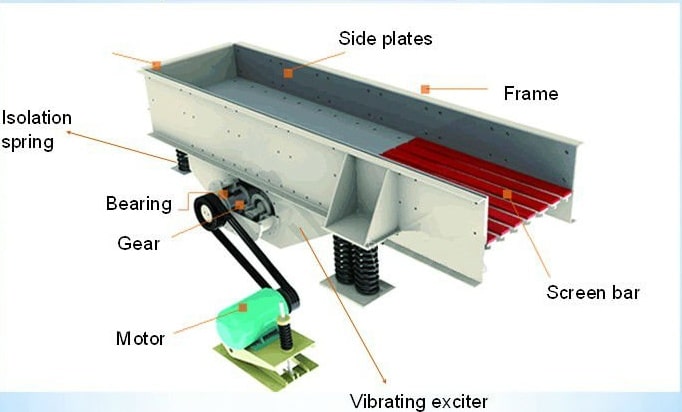

structure and parts

Frame

protected by guard plate, the main unit is convenient for maintenance and allows extended service life.

Isolation bearings

are protected by rubber, less wear and noise.

Oil indicator

convenient for customers to check the lubricating oil.

Gears

with high strength and high precision can ensure the reliable operation.

Motor

are all famous brands, customers can assign the specific brands like Siemens.

Grid clearance (screen bar)

be adjusted according to working conditions; replaceable guard plates for the grid are convenient for maintenance.

features and advantages

- Small volume, lightweight, simple structure.

- Easy to install, repair, low operation cost.

- High efficiency, good feeding capacity.

- Low noise, low power consumption, high power factor.

- Stable vibration, even feeding, long service life.

- The handling capacity of our vibrating feeding equipment is 30tph to 1000tph. And we also can customize according to your demand.

Also the feeder can be divided into a steel plate structure and a grid structure.

The feeder with a steel plate structure is mostly used in a sand and gravel production line to uniformly feed the material into the crushing equipment.

The feeder with a grid structure can roughly screen the material. Make the system more economical and reasonable in the preparation, has become an indispensable equipment in crushing and screening.

Other types of feeder machine

- apron feeder

- vibratory bowl feeder

- screw feeder

- rotary feeder

- belt feeder

- magnetic feeder

- electromagnetic vibrating feeder

- trough feeder

Solutions & cases

Related products

Hydraulic Cone Crusher

the most intelligent cone crusher

Hydraulic Cone Crusher

secondary, tertiary crusher

Primary Jaw Crusher

the most popular primary crusher

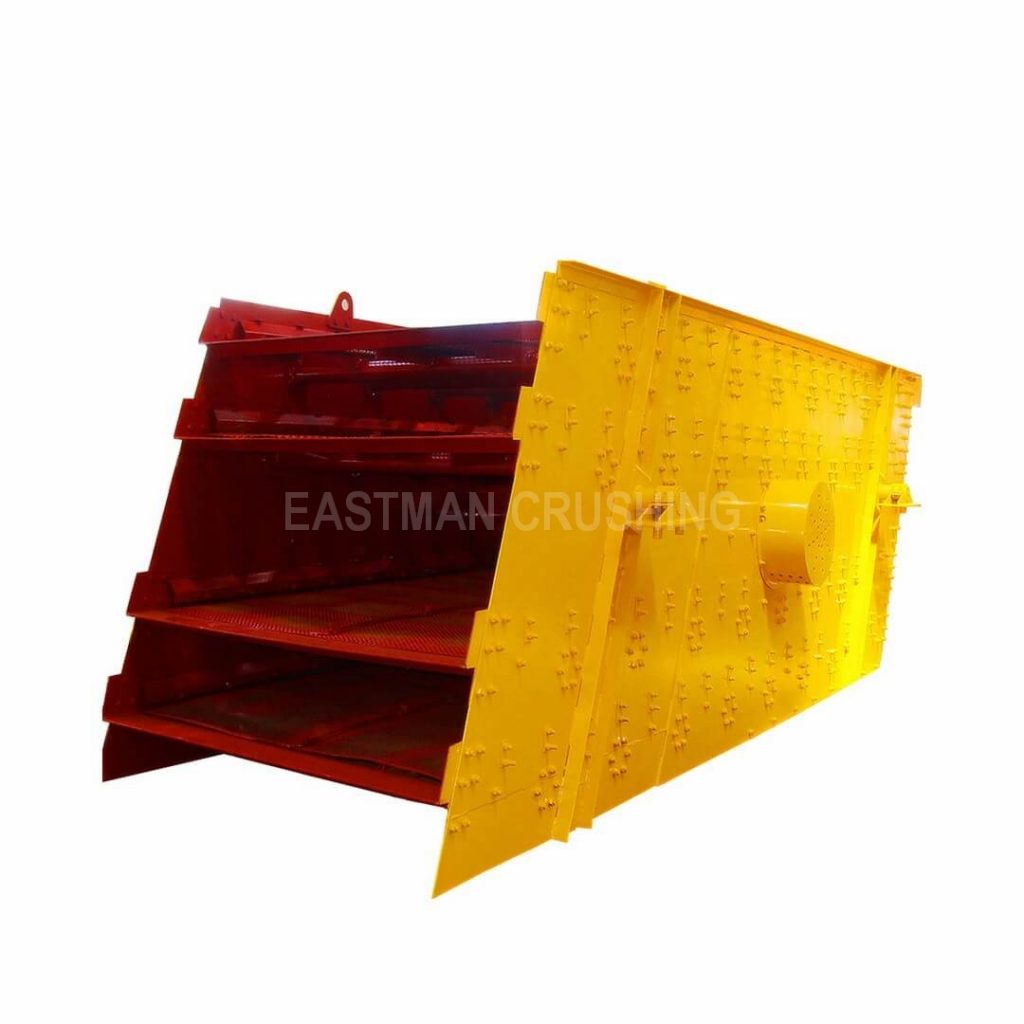

Multilayer vibrating screen

design as you need