construction waste resources Utilization

We would like to work together with you for a better city

hazards of construction waste

Construction waste refers to the solid waste generated during the construction, maintenance, and demolition of buildings, including waste concrete blocks, asphalt concrete blocks, mortar, broken bricks, metals, bamboo wood, waste materials from decoration, and various packaging Materials and other wastes, etc., account for about 30%-40% of the total amount of municipal waste, which is a source of larger municipal waste.

Most of the construction waste is directly piled up in the open or landfilled without any treatment. This treatment method not only takes up a lot of valuable land resources, but also wastes a lot of recyclable building materials, and also increases environmental pollution.

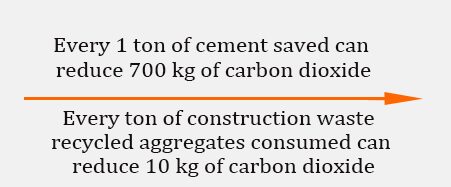

The necessity of recycling construction waste

The resource utilization of construction waste is in line with the policy of developing a circular economy and sustainable development. The resource utilization of construction waste is handled well, and while obtaining environmental benefits, it also has good economic benefits. Construction waste recycled products, including recycled aggregates, recycled inorganic mixtures, recycled bricks, recycled concrete, etc., can be widely used in various road projects, municipal administration, gardens, river slope protection, squares and other fields.

Process and equipment

At present, the widely used utilization methods mainly includes ‘convey construction waste to the fixed crushing plant‘ or ‘on site mobile crusher plant‘.

Fixed crushing plant and equipment

crushing equipment

The objects of the crushing operation are mainly concrete materials and stone, the purpose is to reduce the particle size, increase the uniformity of the shape, and facilitate the subsequent processing procedures. When the crushed construction waste is subjected to separation treatment such as screening, winnowing, and magnetic separation, due to its uniform particle size and increased fluidity, the separation efficiency and quality can be greatly improved, and it is conducive to high-density landfill treatment and saving space.

separation equipment

Through sorting, the useful ones are fully selected and used, and the harmful ones are fully separated, especially the construction waste is divided into different granularity levels for different recycling processes. According to different properties, sorting includes manual sorting, screening, gravity sorting, magnetic sorting, buoyancy sorting, optical sorting, etc.

Screening is the use of a sieve to pass the fine material smaller than the sieve hole through the screen surface, while the coarse material larger than the sieve hole remains on the screen surface to complete the process of separating coarse and fine materials.

mobile crushing plant

Mobile crushing equipment is used to process the construction waste on site, reducing transportation costs and avoiding secondary pollution. Various mobile equipment can be combined with each other as required to produce various recycled aggregates.

Eastman provides tire mobile stations and crawler mobile stations, which can be equipped with crushers, screening machines, and sand washing according to production needs.

custom make base on your requirements

Coarse Crusher

Main equipment: jaw crusher, impact crusher

Coarse crusher mobile station is equipped with high quality jaw crusher and counter crusher. It has strong crushing capacity and good grain type of finished products. It is especially good at crushing hard and abrasive materials.

Applications: Primary crushing, concrete recycling, construction waste disposal, quarry, coal industry, other industries.

Medium-fine crushing and screening plant

Types

★Mobile spring cone crusher and screening plant

★Multi-cylinder cone crushing and screening plant

★Single-cylinder cone crusher and screening plant

★Impact crusher and screening plant

Features

The mobile station can achieve high productivity, large crushing ratio and good grain shape, and is superior in performance, efficiency, production capacity, and finished product quality.

Applications

Crushing + screening mobile station: used for the secondary crushing process, through the free combination of equipment to achieve more complex processing requirements

Fine crushing, shaping and screening plant

Main equipment: VSI sand making machine, impact crusher

The mobile impact crushing and screening plant is equipped with high-performance, large crushing ratio, powerful crushing VSI sand making machine and impact crushers. It is a reasonable equipment in the field of artificial sand making and stone shaping. It integrates professional crushing technology and a model of mechanical manufacturing. Accurate classification of finished products.

Applications

Suitable for material fine crushing and shaping.

Fine crushing, sand washing plant

Types

Impact crusher + sand washing machine

Cone crushing + sand washing machine

Features

The right choice for processing construction sand and road construction sand. Equipped with a spiral sand washing machine, it is suitable for washing, grading and impurity removal in metallurgy, building materials, hydropower and other industries.

Applications

Processing of crushed or collected sand or finished sand

In areas with high environmental protection requirements, the production line is equipped with sand washing equipment, which can effectively remove dust and noise, and reduce dust pollution.

Get our product detail & price

Quick quotation, free crushing flow design, on-site service! Respond to you within 24 hours.