VSI sand making machine

Capacity

120-640t/h

Input size

30-50mm

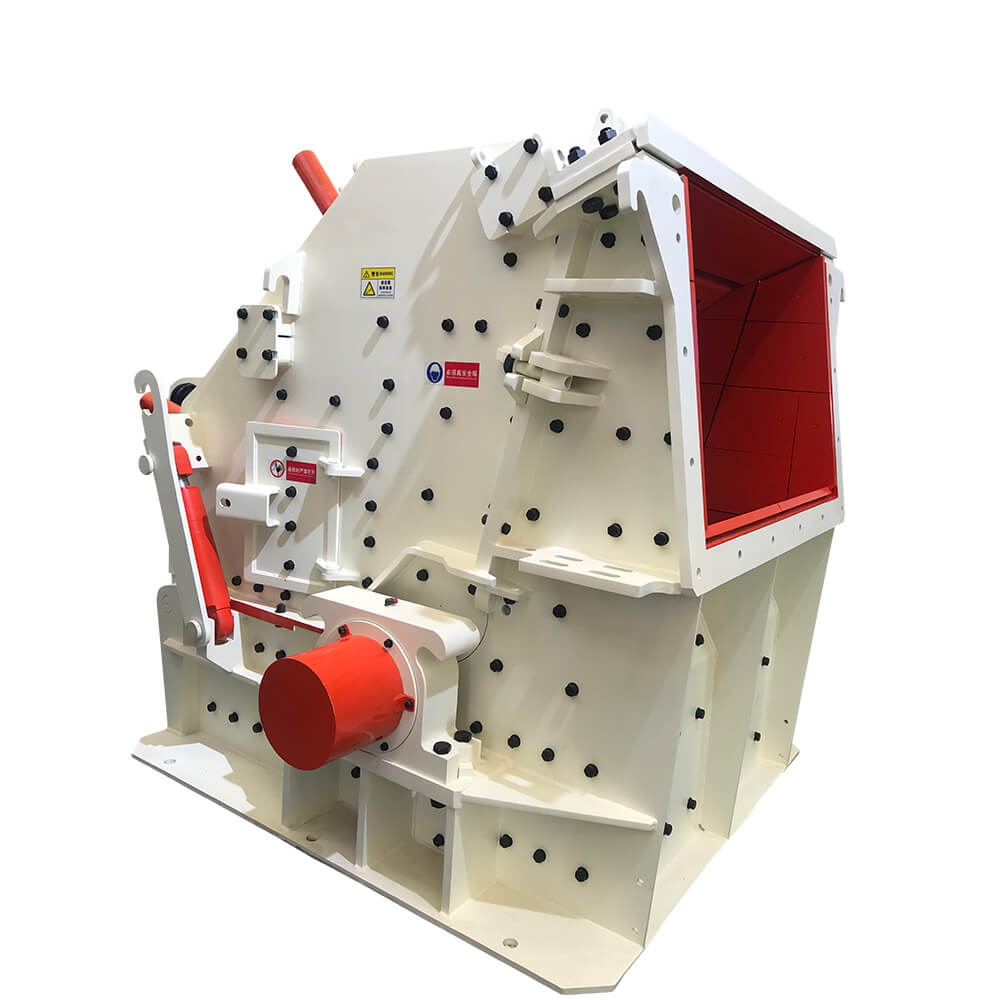

VSI Sand Making Machine is known as vertical shaft impact crusher, which is commonly used as sand maker and shaper in the final stage of crushing and grinding circuit.

Applications

Quarry, sand concrete, dry mortar, manufactured sand, power plant desulfurization, quartz sand, etc.

Materials

Cobble, granite, basalt, iron ore, limestone, calcite, quartzite, diabase, etc.

Hot Sale

VSI7611

Capacity: 120-180t/h

Feed size: 35mm

Motor: 110Kw

VSI8515

Capacity: 200-260t/h

Feed size: 40mm

Motor: 180Kw

Eastman sand making machine series

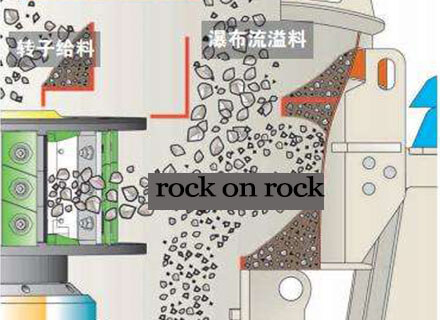

Rock on rock crush

This is a rock on rock (autogenous) crusher, whereby no wear parts are used to crush the rock.

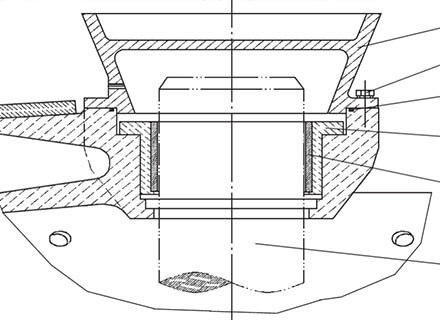

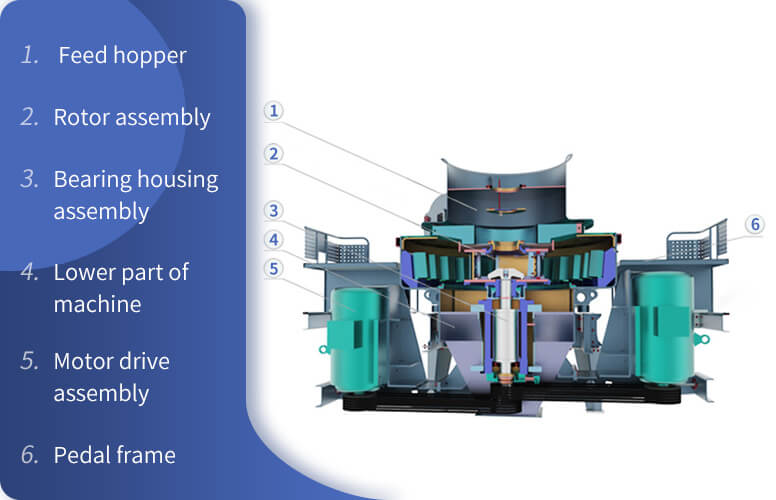

Bearing Sealed structure

The sealing structure prevents oil leakage and dust from entering the bearing barrel.

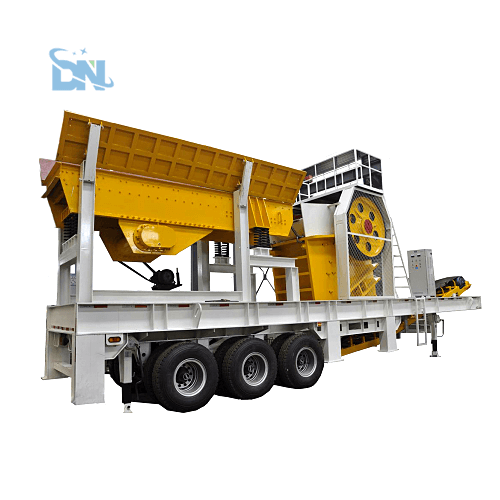

Stationary, mobile version

Mobile VSI sand making machine (wheel or crawler type) easily moves in different applications.

VSI Maker was first manufactured by the German. Our factory adopted this advanced technology and made some improvement on its rotor structure. Now it is the fourth generation of high-performance sand making equipment with the great improvement and optimized design.

Simple open table and enclosed rotor designs provide reliable performance and low maintenance.

Sand Making machine working principle

Eastman VSI Sand Making Machine

VSI crusher Technical specifications

Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

Capacity (T/H) | Center And Ring Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

Best Feed Size (MM) | Soft Material | 35 | 40 | 45 | 50 | 50 |

Hard Material | 30 | 35 | 40 | 45 | 45 | |

Rotation Speed (R/MIN) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1200-1390 | |

Power For Double Motor (KW) | 110 | 180 | 264 | 400 | 440 | |

Dimension L×W×H (MM) | 3700×2150 ×2100 | 4140×2280 ×2425 | 4560×2447 ×2778 | 5000×2700 ×3300 | 5100×2790 ×3320 | |

Weight (t) | 11.8 | 14.5 | 17.8 | 25.6 | 26 | |

Power Soppty | 380V 50Hz | |||||

Vibrating Sensor | Monitering Range:0.1-20MM/S Continuousely Adjustable | |||||

Lubrication Hydraulic Station | Dual Oil Bump Motor Power | 2×0.25kW | ||||

Security Protection | Double Oil Pump Ensure The Normal Oil Supply; Automatic Shut Down If No Oil Pressure; Water Cooling; Motor Preheating In Winter. | |||||

Over Dimension L×W×H(mm) | 820×520×1270 | |||||

Oil Tank Heating Power | 2KW | |||||

VSI Crusher has min. wear and max. profits

A properly configured VIS is the key to reducing wear costs and downtime and maximizing profits.

- The crushing cavity internal items can be changed or repaired easily and fast because of adopting hydraulic device.

- With the unique feeding structure it is convenient to realize the ‘rock on rock” and “rock on ore”can crush and shaping stones.

- Dustproof sealing system completely avoid the external dust into the lubricating parts.

- High quality materials and advanced technology improve the equipment quality and performance.

- The best design of crushing cavity prolong the service time of wearing parts and reduce the cost.

- Feeding pipe of high abrasive alloy material has a long service life

- Feeding distributor are made of high chromium iron wear resistant material high manganese steel plate

- Enclosed rotor designs provide reliable performance and low maintenance.

- Forged hardened and tempered chrome molybdenum steel, large diameters to suit heavy duty application.

- Vertical bearing are produced by the largest manufacturer nationwide and they can support the upper part effectively.