sand making Plant

VSI Sand Making Machine

Capacity: 120-640t/h

Input size: 30-50mm

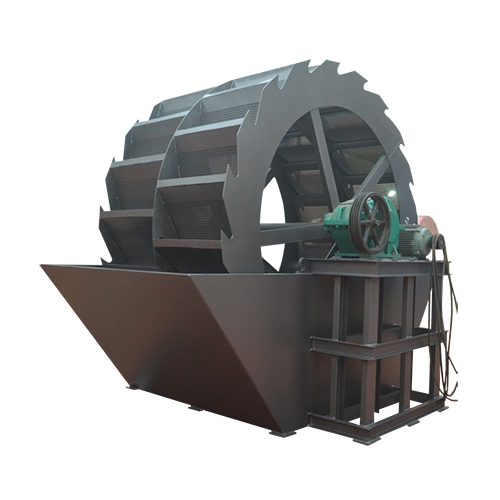

Wheel Type Sand Washer

Capacity: 15-200TPH

Feeding size: ≤10

Spiral Type Sand Washer

Capacity: 30-200TPH

Motor: 7.5-22Kw

Description: Sand Plant (Sand making plant) produces high-quality artificial sand, an alternative of river natural sand, for the building, construction industries where demand high quality aggregates.

Materials: According to different demands, sand making plants include pebble sand production line, limestone sand production line and the like. All of which could produce aggregates from granite, basalt, pebbles, limestone, river pebbles, calcite, slag, etc.

Applications: It can crush various of rocks into different particle size, with uniform shape and high compressive strength, artificial crushed sand is high quality aggregate for highway, railway, water conservancy, concrete mixing station and other industries.

Description: Sand Plant (Sand making plant) produces high-quality artificial sand, an alternative of river natural sand, for the building, construction industries where demand high quality aggregates.

Materials: According to different demands, sand making plants include pebble sand production line, limestone sand production line and the like. All of which could produce aggregates from granite, basalt, pebbles, limestone, river pebbles, calcite, slag, etc.

Applications: It can crush various of rocks into different particle size, with uniform shape and high compressive strength, artificial crushed sand is high quality aggregate for highway, railway, water conservancy, concrete mixing station and other industries.

sand making production line

sand making production line

Sand making plants are operating as followings:

Firstly, the materials go to primary crusher (Jaw crusher) for primary crushing. Then the materials are transferred by the belt conveyor to secondary crusher (Cone crusher) for further crushing.

Then the vibrating screen will grade the materials, where stones that meet the granularity standard will be sent to VSI crusher (sand-maker), while the rest will be returned for another round of crushing.

Part of the stones processed by VSI crusher (sand maker) will be made into sand and become sand products after being washed. The rest will be further crushed by the sand maker into qualified sand materials of various types.

Sand making production line consists of vibrating feeder, Jaw Crusher, Cone Crusher, Impact Crusher (sand-maker), vibrating screen, sand washer (sand classifier), belt conveyor, water treatment system and centralized electronic control system. We could also add a dust separator to the line to meet the specific requirements of our clients. We could assemble the production line according to the requirements of various processes to ensure the line has the best performance.

Main equipment lists in sand making process:

- jaw crusher,

- cone crusher,

- impact crusher(sand maker),

- VSI sand maker,

- sand washing machine,

- vibrating feeder,

- vibrating screen,

- belt conveyor, etc.

Sand making flow: Raw material first enter the primary crusher (usually a jaw crusher) for the primary crushing, and then the primary crushed materials are transferred to the secondary crusher (usually a cone crusher, or impact crusher) through belt conveyor. The vibrating screen is placed after the secondary crusher to screen crushed materials, where undersized materials meet the granularity standard will be sent to VSI sand making machine to further fine crushed, and the rest of over size stones are be returned to the secondary crusher. The last step is sand washing, wash away powder, clay and so on. As the crushing circuit goes on, the raw big materials will be crushed into qualified size manufactured sand that used in industry.

soft Stone crushing plant configuration

soft Stone crushing plant configuration

50-100TPH limestone (soft material) crushing line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN380*95 | 1 |

| Jaw crusher | PE500*750 | 1 |

| Imapct crusher | PF1210 | 1 |

| Vibrating screen | 3YD1548 | 1 |

100-200TPH limestone (soft material) crushing line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN490*110 | 1 |

| Jaw crusher | PE750*1060 | 1 |

| Imapct crusher | PF1214 | 2 |

| Vibrating screen | 3YD2160 | 1 |

200-300TPH limestone (soft material) crushing line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN600*130 | 1 |

| Jaw crusher | PE1000*1200 | 1 |

| Impact crusher | PF13115 | 2 |

| Vibrating screen | 3YD3070 | 1 |

300-400TPH limestone (soft material) crushing line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN600*130 | 1 |

| Jaw crusher | PE1000*1200 | 1 |

| Imapct crusher | PF13115 | 3 |

| Vibrating screen | 3YD2460 | 1 |

| Vibrating screen | 3YD1860 | 1 |

hard Stone crushing plant configuration

hard Stone crushing plant configuration

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN380*95 | 1 |

| Jaw crusher | PE600*900 | 1 |

| Imapct crusher | PF1315 | 1 |

| Vibrating screen | 3YD1860 | 1 |

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN490*110 | 1 |

| Jaw crusher | PE750*1060 | 1 |

| Imapct crusher | PF1325 | 2 |

| Vibrating screen | 3YD2160 | 1 |

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN600*130 | 1 |

| Jaw crusher | PE1000*1200 | 1 |

| Cone crusher | HP500 | 2 |

| Vibrating screen | 3YD2426 | 1 |

| Vibrating screen | 3YD1860 | 1 |

300-400TPH granite (hard material) crushing line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN600*130 | 1 |

| Jaw crusher | PE1000*1200 | 1 |

| Cone crusher | HP400 | 2 |

| Impact crusher | PF1515 | 1 |

| Vibrating screen | 3YD3070 | 2 |

Sand making plant configuration

Sand making plant configuration

50-100TPH pebble artificial sand making line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN380*95 | 1 |

| GP cone crusher | DP100S | 1 |

| VSI sand making machine | VSI7611 | 1 |

| Vibrating screen | 3YD1860 | 1 |

| Wheel type sand washer | XS30016 | 1 |

100-200TPH granite artificial sand making line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN590*110 | 1 |

| Jaw crusher | PE800*1060 | 1 |

| HP cone crusher | HP300 | 1 |

| Vibrating screen | 3YD2460 | 1 |

| VSI sand making machine | VSI7611 | 1 |

| Vibrating screen | 3YK1860 | 1 |

200-300TPH limestone artificial sand making line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN600*130 | 1 |

| Jaw crusher | PE1000*1200 | 1 |

| Impact crusher | PF1315 | 2 |

| Vibrating screen | 3YD2460 | 1 |

| VSI sand making machine | VSI8518 | 1 |

| Vibrating screen | 3YK2160 | 1 |

FAQs

What’s your sand making machine application?

Our Eastman sand making machines are mainly be used to those types of sand making process:

1.Manufactured Sand Making

2.Artificial sand Making

3.Sand gravel making

4.Crushed sand making

5.Silica sand making

6.Quartz sand making

What’s the types of your sand making machines?

We have the special sand making machine like VSI crusher, sand screening machine like vibrating screen, also we have sand washing machines like wheel sand washer and spiral sand washer. These sand crushing, washing and screening equipment are for maximum productivity. We also supply individual crushers and screens, as well as the key components and wearing parts.

What about your sand making plant flow design?

We can help customers design those plants include quartz sand production line, building sand production line and stone material production line, all of which could produce aggregates and crushed sand from limestone, granite, basalt and river stone. Especially we have a lot of experience in sand plants and sand washing plants with river stone. All these products are widely used in the construction of hydraulic power plants, building material, highway, and urban infrastructure.

What about your services?

We offer complete pre-sale, sale and after-sale services. Also we can provide free help to assemble sand plant (sand-making production line) according to our client’s requirement for material size, productivity and usage. We design the process in line with the production site of our clients so as to bring our clients the most rationally designed and the most economically efficient sand plant.

What’s your advantages?

Typically our designed sand production line adopts a high level of automation and low operation cost, featuring high crushing efficiency, energy conservation, great productivity, less pollution and easy maintenance. Also, Stone products produced by our eastman well designed production line get excellent shape, meeting the national standard for high-speed feeding materials.

What’s your advantages?

Typically our designed sand production line adopts a high level of automation and low operation cost, featuring high crushing efficiency, energy conservation, great productivity, less pollution and easy maintenance. Also, Stone products produced by our eastman well designed production line get excellent shape, meeting the national standard for high-speed feeding materials.