Cone Crusher

300TPH Cone Crusher Rock Basalt Crushing Plant

| Anhui customer | Details |

| Material | Basalt |

| Feeding size | <600mm |

| Final product size | 5-10mm, 10-15mm, 15-30mm |

| Capacity | 300TPH |

| Total cost | $80,000-$150,000 |

| Main equipment | vibrating feeder, jaw crusher, cone crusher, vibrating screen, conveyor belt |

800TPH Basalt Crushing Plant

| Henancustomer | Details |

| Material | Basalt |

| Feeding size | <1000mm |

| Final product size | 0-5mm, 5-10mm, 10-20mm, 20-40mm |

| Capacity | 800TPH |

| Total cost | $150,000-$200,000 |

| Main equipment | vibrating feeder, PE-1200×1500 jaw crusher, GP cone crusher,2 sets HP300 cone crusher, PF-1820 impact crusher, 3YK3072vibrating screen,conveyor belt, etc |

Quick quotation, free crushing flow design, on-site service! Respond to you within 24 hours.

FAQ

The price of the cone crusher is very different from cheap to expensive (about $10,000-$1000,000), mainly related to production capacity and equipment type. Get a quick and accurate price!

1. Production capacity

The output of all cone crushers is between 36-2180t / h. The higher the output, the more expensive the price. Among them, the highest output is the new model single-cylinder cone crusher output 2180 t/h.

2. Technology type

Some use single hydraulic technology, some use mixture of mechanical, hydraulic, electrical and intelligent. Single-cylinder cone crusher, multi-cylinder cone crusher, full hydraulic cone crusher, the price decreases in order.

3. Crushing materials

Most of the cone crushers only single cavity, if need different multi cavities according to the materials, the price goes higher surely. Most used cone crusher output is 300-400 TPH, and the price is range from $40,000 to $100,000.

Engineer helps select the right crusher!

- GP Single-cylinder cone crusher, $40,000-70,000.

1. Model SC250: cavity type F1, production capacity below 396 t/h, feeding ≤215mm, discharge 16mm, motor power 250KW.

2. Model SC315: cavity type F1 / F2 / F3, all three can reach this standard, the production capacity is between 162-662t / h, the feeding size is 85-275mm, and the discharging particle size is 13-16mm.

3. Model SC250S: mainly for medium crushing stage, production capacity 225-605 t/h, feed size 400-450mm, discharge particle size 22-35mm. - HP Multi-cylinder cone crusher, $40,000-$80,000

1. Model HP300: C1 / C2 / C3, the three cavity types can reach the output of 300-400 hourly, the feeding size is 115-200mm, the adjustment range of the discharge port is 16-45mm, and the motor power is 220KW.

2. Model HP500: the feeding particle size is 75-285mm, the discharge port adjustment range is 8-51mm, and the motor power is 400KW. Low consumption.

- Come to the factory, airport pickup, free test machine.

- Tailor-made process flow, provide installation, commissioning, training operator and other services.

- Maintenance guide to solving various after-sale problems for you.

Raw material: granite

Output: 200t/h

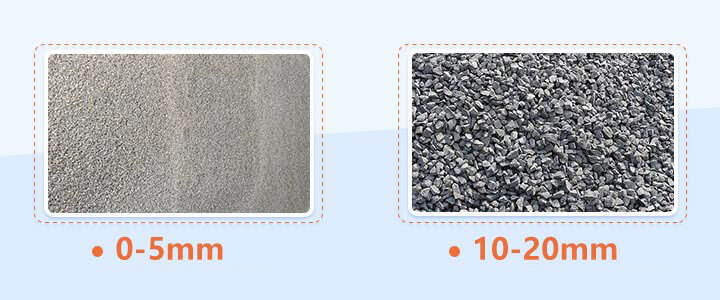

Finished product: 0-5mm, 10-20mm

These are two kinds of finished materials with different specifications. Due to the high hardness of the raw material granite, the selected equipment mainly includes the following:

1. Primary crusher: jaw crusher

2. Fine crushing: HP300 Cone crusher

3. others: bin, vibrating feeder, vibrating screen, conveyor belt.