Which Equipment Is Best For Crushing Wet Coal

Coal is a mineral, and it is also a mineral that has important applications in our production and life. For the application of coal, it needs to be processed into a suitable particle size before application. Wet coal can be processed and crushed into sand and used in various industries, such as roads, railways, construction, etc., to achieve the effect of waste recycling. The investment profit of wet coal sand processing is considerable, and more and more customers are focusing on wet coal sand making.

Why is wet coal difficult to crush

Coal is an important source in industrial production and is known as the “food grain” of industry. It has a high content on the earth and is widely used. In order to make the best use of resources in the process of coal development and utilization without waste and environmental pollution, the selected crushing equipment is very important.

The so-called wet coal refers to coal with a relatively large water content. This material is characterized by high water content, high viscosity, high water holding capacity and low heating value. If the selected equipment is not suitable for processing, it is prone to blockage and other phenomena. So who is better for handling wet coal?

Wet Coal crushers

1. Wet Coal Jaw crusher:

(1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity. Simulate the movement of two jaws of an animal to complete the material crushing operation;

(2) Specifically, the jaw wet coal crusher is suitable for feeding granularity of 1200mm, with a wedge-shaped adjustment outlet. The particle size adjustment range of the finished product is 10-350mm, and the particle size is uniform, which is helpful for secondary crushing treatment;

(3) The jaw crusher has an output of 1-1000 tons per hour, the crushing cavity is deep, and there is no dead zone, which improves the feeding capacity and output. The flywheel design effectively reduces vibration, making the machine run more stably and more efficiently.

(4) Generally speaking, the jaw crusher is often used as a coarse crusher, which is in the breaking head position in the wet coal production line.

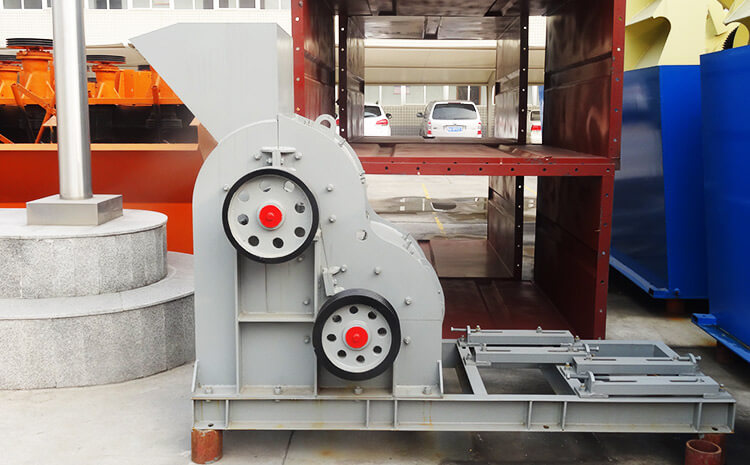

2. Wet coal hammer crusher:

(1). The wet coal hammer crusher mainly relies on the impact force of the hammer to crush the material. At the same time, the material enters the machine from the upper feeding port, and is crushed by the impact, impact, shearing and grinding of the high-speed moving hammer.

(2). Hammer wet coal crusher is suitable for feeding particle size 1200mm. By changing the cavity type, coarse, medium and fine crushing can be achieved. The finished product is 3-60mm, without flakes, the blank body is smooth, with multiple edges and corners to ensure the compressive strength. Especially suitable for highway, construction and large engineering materials.

(3). Hammer wet coal crusher is suitable for feeding size 1200mm. By changing the cavity type, coarse, medium and fine crushing can be achieved. The finished product is 3-60mm, without flakes, the blank body is smooth, with multiple edges and corners to ensure the compressive strength. Especially suitable for highway, construction and large engineering materials.

(4). The output of the hammer crusher is 80-3000 tons per hour, which can achieve primary crushing and molding without secondary crushing and molding process, with high production efficiency and greatly reduced cost.

3. Double-stage crusher: When the double-stage crusher is working, driven by the motor, the two sets of rotors connected in series rotate at high speed at the same time. At the same time, the materials in the cavity also collide violently with each other, and the materials are crushed twice to become finer and more uniform, and finally the materials that meet the particle fineness requirements are directly discharged.

(1) High crushing efficiency: Compared with ordinary coal crushers, this new type of coal double-stage crusher adopts double rotors for upper and lower crushing, which has high crushing efficiency and large output;

(2). Wider scope of application: The new double-stage crusher adopts the design of bottomless screen, which is especially suitable for materials with high humidity and moisture. drying rate;

(3). Easy control of particle shape: To control the size of material particles, it is only necessary to adjust the gap between the upper and lower hammer heads of the double-stage crusher;

(4). Strong wear resistance of components: The new double-stage crusher adopts high wear-resistant hammer heads and hammer handles cast from hard metal materials, which are durable and can be used for one pair of hammer heads.

Advantages of our Wet Coal Crusher

1. Uniform particle size and high sample preparation efficiency

Before entering the crushing cavity, the materials with a certain humidity are screened in the movable sieve plate system. The fine materials and small particles directly enter the discharge port, and the large-sized materials enter the crushing cavity and are crushed and pass through the grate plate. The material falling into and out of the material outlet can be adjusted freely, and the particle size of the material is uniform, and the sample preparation efficiency is high.

2. Low pollution is more environmentally friendly

The wet coal crusher adopts a fully dense design, and there is no dust pollution during work, which fully meets the requirements of environmental protection. The operation is stable, the noise is low, and it meets the requirements of safe production.

3. Advanced design and good output

The accessories are advanced, and the slats of the wet coal crusher are made of high-strength special materials, which can be quickly loaded and unloaded. It is very convenient in operation, maintenance and maintenance, with simple structure and convenient operation. It can be used alone or incorporated into a joint sample preparation unit to form a streamlined operation.

4. Crushing a variety of materials

The wet coal crusher can crush all kinds of medium-hard and weakly abrasive materials. Mainly used in coal, electric power, scientific research and other industries and departments to crush and dry coal, ore, rock, limestone or other medium hardness materials containing more than 15%. No sieve bars, overcoming the problem of high humidity and easy clogging.

5. Durable

The rotor of the wet coal crusher can be reversed, which improves the utilization rate of the hammer head. The casing and rotor adopt finite element analysis technology to ensure the service life. The super wear-resistant hammer head can increase the service life by 50%-150% compared with the general high manganese steel hammer head.

In short, which type of crusher to choose, we will choose the appropriate equipment to maximize your interests according to your actual situation. The price of the wet coal crusher is determined by the manufacturer’s type, equipment model, manufacturing process, etc. For the specific price, you need to consult Eastman’s professional engineers. According to your actual situation, we will design a sand making and crushing production line plan for you, and give you an accurate quotation.