200TPH Aggregate Making Plant in Ghana

Material: Granite

Capacity: 200TPH

Output size: 0-5mm, 5-15mm, 15-31.5mm

Input Size: 0-630mm

Country: Ghana

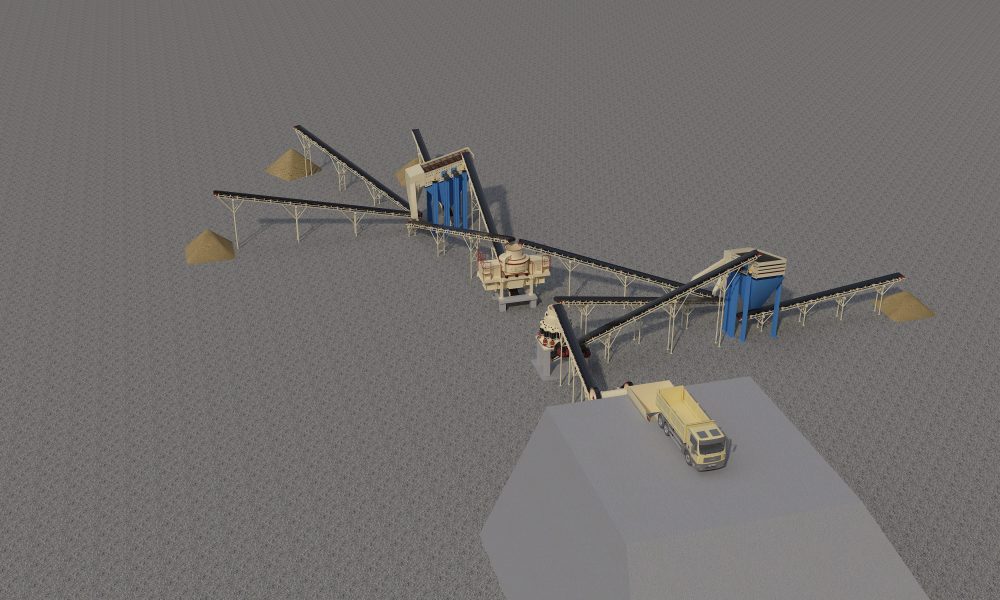

Schematic Diagram of Process Equipment

Equipment Used

- Hopper

- Vibrating feeder DN4911

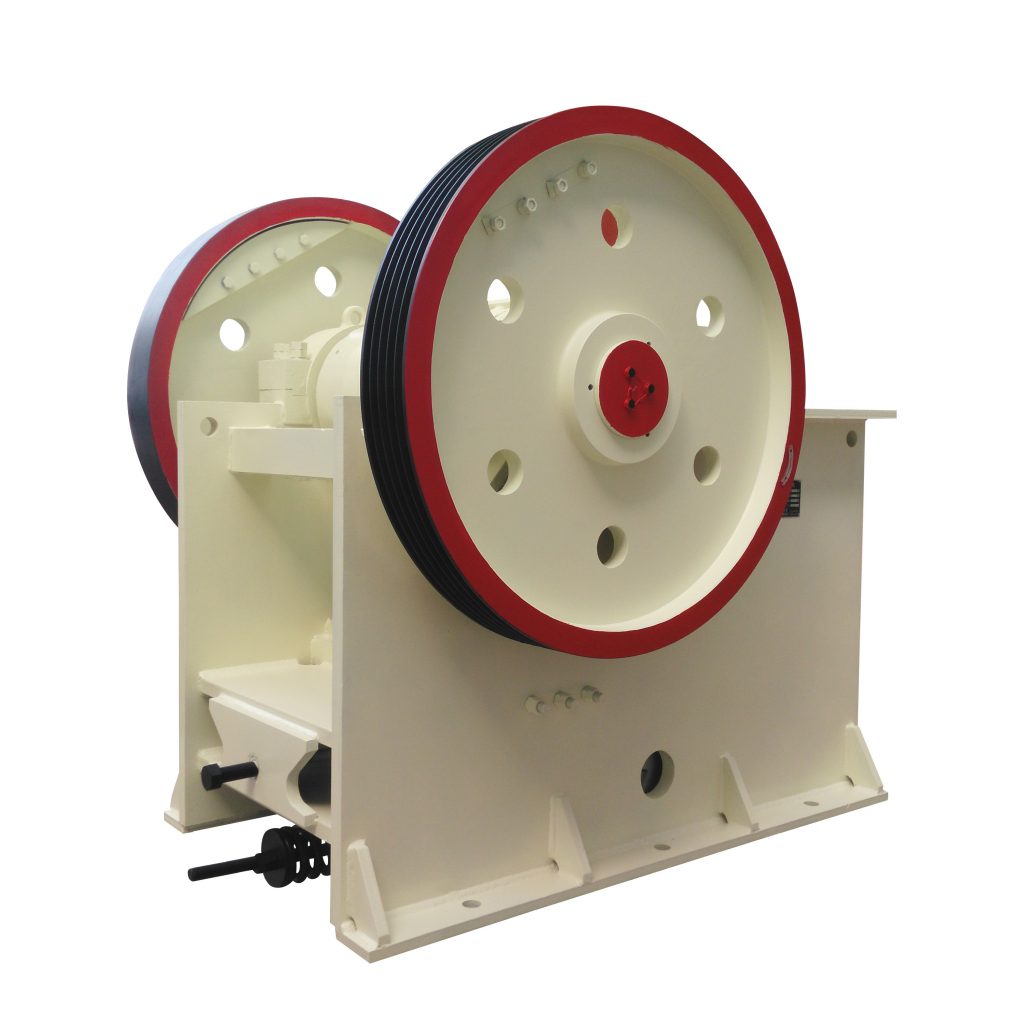

- Primary jaw crusher PE-750*1060

- Cone crusher DN1400

- Vibrating screen 2YD2160

- VSI DN9000

- 3-layer vibrating screen 3YD2160

- Belt conveyors.

Flow Description

Our Ghana customer use the truck to unload the stones into the hopper.

Feeding: The stone will enter the vibrating feeder from the lower part of the hopper. And the vibrating feeder feeds the stones evenly to the primary jaw crusher. (The crushing equipment here uses a primary jaw crusher and a secondary cone crusher.)

Primary and Secondary Crushing: The crushed output materials from the jaw crusher will be transported to the cone crusher by a belt conveyor. Then the crushed output materials from the cone crusher will be transported to a vibrating screen(two layers).

Screening: We can get 0-5mm, 5-35mm, +35mm materials after screening by the two-layer vibrating screen.

Product Circulation: The 0-5mm materials will be transported out by a belt conveyor to stockpile, 5-35mm materials will be transported to VSI Crusher, and +35 materials will be transported back to cone crusher for re-crushing.

Crushing: For 5-35mm materials, they are crushed and shaped by a VSI crusher, the output materials will be transported to the second vibrating screen.

Screening: After the second vibration screen, it will get 0-5mm, 5-15mm, 15-31.5mm materials, the +31.5mm materials will be transported back to the VSI crusher.

Supplement:

- The role of the VSI crusher in this setup for producing high standard output materials for mixing stations, asphalt stations, etc.

- This crushing plant is suitable for processing many kinds of hard stones, like basalt, pebbles, granite, diabase, etc.

- The capacity for this crushing plant can be customized as per request such as 50tph, 100tph, 200tph, etc

Our Advantages

➤Professional Engineers Team

Tell us raw material of your aggregate plant, input size, output size, and capacity. Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you. Also, our engineers can design the flowchart according to your needs. Answer any aggregate questions for you.

➤Excellent Crusher Manufacturers

Our company was founded in 1985. In the aggregate crushing industries, we have 35+ years of machinery production of experience. All the equipment of stationary crusher plant, mobile(portable) crusher plant are choose the best materials, and meticulously casting every part. High Performance & Ease of Operation, many crushers equipment in stock.

➤Good Service

We have a office in Tanzania.The customers of regions near Tanzania and Tanzania, we provide installation service for free. All of our equipment, 1 Year Warranty.