Correct Selection Of marble Crushing Equipment

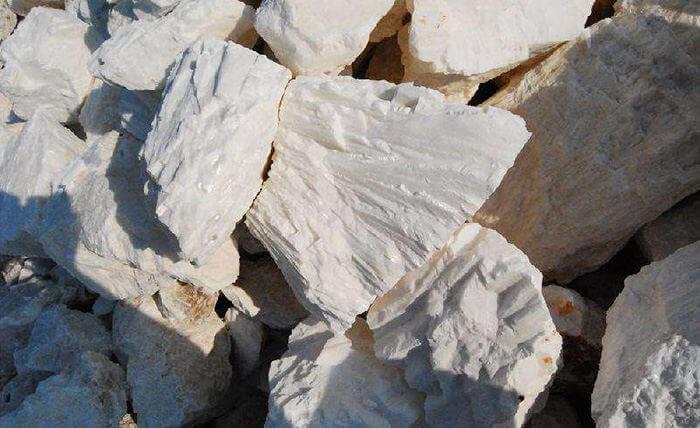

Marble originally refers to white limestone with black patterns, which is a metamorphic rock formed under the action of high temperature and high pressure in the crust. The main ingredient is calcium carbonate, which has no deformation, high hardness, long service life, and no magnetization. Generally, it will be processed into stones. It is a good raw material for sand and gravel, with a normal hardness of 2.5-5 on the Mohs scale. It can be used to make construction stones or construction sand, etc.; so what equipment is better for marble crusher?

About Marble crushing

Marble, also known as cloud stone, is recrystallized limestone. Generally refers to marble, limestone, dolomite, and skarn and marble formed by different alterations of carbonate rocks. The general physical properties of marble are relatively soft, which is relative to granite. Marble is a trade name, not a petrological definition.

Marble is a major category of natural architectural decorative stones, which generally refer to decorative functions. In interior decoration, marble is suitable for TV table tops, window sills, and indoor floors. Metamorphic or unmodified carbonate rocks that can be processed into building stones or handicrafts. Marble processing belongs to non-metallic, and the processed finished stone sand is often used to supply mineral raw materials. After being processed by crushing and sand making equipment, its value doubles and it becomes a mechanism sand and gravel material that is in short supply.

Crushing Marble Equipment - Coarse Crusher

1. Jaw crushers and hammer crushers are more suitable for coarse crushing. Jaw crusher is a relatively common coarse crushing equipment, which has the advantages of strong wear resistance and high compression resistance. Moreover, it is small in size and easy to install on site, and the principle of stone-on-stone crushing can be realized for marble by extrusion. Using the dynamic and static jaws to simulate the animal bite mode to complete the crushing, it can crush the stones with a size of about 1200mm into a size below 600mm;

2. The hammer crusher can also be used as a first-stage crusher with a large crushing ratio, and the rough crushing process can be completed by hammering the stone in the way of hammering. The hammer crusher has a deep feed inlet, a large crushing ratio, and also has the function of stone shaping. The crushed marble stones have uniform particle size, less stone powder content, and the feed particle size is between 1200mm. Under the design of no sieve bottom grate, it is only necessary to adjust the gap between the rotor and the blow bar to control the particle size.

Crushing Marble Equipment - Fine Crusher

There are two types of fine crushing equipment: impact crusher, VSI sand maker and double roller crusher.

1. The impact crusher is a commonly used secondary crusher, which is generally used to crush marble stones again after the jaw crusher. Using the deep cavity crushing method, the stones falling into the crushing cavity are crushed by the friction and collision between the impact plate, the hammer head and the rotor. Then the crushing of the stones is completed in the collision between the stones, and the output particle size is uniform and the content of stone powder is small;

2. The VSI impact sand making machine is actually a kind of sand making machine in the fine crushing equipment, which can complete the production and processing of marble stones with a feed particle size of 50mm according to the construction sand standard. Center feed + peripheral feed or center feed + cascade feed. The stones falling into the crushing cavity are processed for sand making, realizing the way of stone shaping and sand making. The crushed finished product has uniform particle size and finer discharge, and the finished product can be adjusted between 1-5mm.

The sand making machine is mainly used to finely crush the marble waste to make sand. It adopts a better angle design of the crushing cavity, and the design is more special, which can realize one machine with multiple functions. Its processing capacity and throughput are better improved, and the parts are not easy to wear, which greatly reduces the operating cost of the equipment. The hydraulic cover opening device system adopted is relatively simple and convenient for inspection and maintenance. The fineness modulus can be adjusted, and the finished product has a better grain shape, which is safe and environmentally friendly.

3. Fine crushing available on the double roller crusher:

1. Low cost: The advanced crushing technology and high-quality raw materials have been transformed, with simple structure, convenient operation and low failure rate. Effectively reduce infrastructure investment and maintenance costs, greatly reducing operating costs.

2. Safe and reliable: the equipment operates very stably. In addition, it also has an advanced safety protection device, which has the performance of passing iron and can effectively filter metal parts. Prevents accidental breakage of the crusher, increasing safety and reliability.

3. Reduce dust-proof noise: Install dust-proof boards and sealing devices inside the roller crusher to prevent dust and particles from spreading, and reduce equipment vibration and dust pollution. The working noise is controlled within 68 decibels to prevent noise pollution.

4. Reduce energy consumption: After reasonable optimization, the double-roll crusher equipment has low requirements for material moisture and no adhesion phenomenon. Effectively reduce kinetic energy, save energy consumption, and adopt automatic hydraulic avoidance system. Further achieve the purpose of energy saving and consumption reduction.

5. Environmental protection and high efficiency: the roller crusher adopts the advanced principle of low-speed and high-pressure crushing, which can withstand greater pressure and greatly improve the fracturing efficiency. At the same time, there is almost no noise and dust pollution during the crushing process of the equipment, and the environmental effect is good.

marble crushing plant

The first stage: crushing, sand making

The materials that have been coarsely crushed by the jaw crusher must be classified by screening equipment. If the size is below 40mm, they can directly enter the sand making machine. If it is not achieved, it will enter the secondary crushing equipment for crushing, and the impact crusher and cone crusher can be selected.

The second stage: grinding

After being crushed by the jaw crusher, the bulk material is sent to the storage bin by the bucket elevator, and the material is evenly, quantitatively and continuously sent to the grinding chamber by the electromagnetic vibrating feeder for grinding. The ground powder is blown to the classifier under the action of the blower for sorting. After sorting, the unqualified powder falls back and continues to be ground, and the qualified fine powder is sent to the storage bin through the pipeline, and finally the finished powder is output through the discharge valve. The entire process flows under negative pressure, and the increased air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine, and enters the small cyclone collector for purification treatment.

The marble crushing production line we configure has low cost, stable operation and few failures, which is very suitable for your sand and gravel plant needs!

Features of marble crushing line

1. The equipment is reasonably equipped, the operation is more stable, the entire production line is smooth, and there are fewer failures. Compared with other production lines, it can save the cost of later repairs and maintenance.

2. The space layout is scientific, the floor area is small, the basic investment cost is saved, and the installation and operation are simple and convenient.

3. High efficiency and large output, the unit production capacity is 1.5 times that of the traditional production line of the same scale.

4. Select high-quality motor equipment, reduce power consumption, and save nearly 40,000 yuan in water and electricity costs during work;

5. Green, less pollution, fully control dust, noise and other pollution within a reasonable range, to achieve the purpose of low-carbon and environmentally friendly production.

In short, which type of crusher to choose, we will choose the appropriate equipment to maximize your interests according to your actual situation. The price of the marble crusher is determined by the manufacturer’s type, equipment model, manufacturing process, etc. You need to consult Eastman’s professional engineers to get the factory price. According to your actual situation, we will design a sand making and crushing production line plan for you, and give you an accurate quotation.