What Kind of Crushing Equipment is Good for HPB Production?

What is HPB?

HPB is the crushed stone that fraction size is 5-10 mm, which is one of the main aggregates of shotcrete. It’s also called ¼” crushed stone (5-10 MM). With the development of China’s infrastructure projects, the demand for HPB stone is increasing year by year, and there are more and more HPB crushing equipment and manufacturers. Many customers have made difficulties in choosing. What kind of crushing equipment is good for the production of ¼” crushed stone? Which manufacturers’ equipment is more reliable?

What Kind of Crushing Equipment is Good for HPB Production?

There are many kinds of crushers, including jaw crushers, cone crushers, counterattack crushers, hammer crushers, impact crushers, mobile crushing stations, counter roll crushers, fine crushers, etc. They have different output, different feed and discharge particle sizes, and different applicable raw materials.

Generally speaking, jaw crushers and hammer crushers have large feed particle sizes and large discharge particle sizes. They can be used as primary equipment and can not directly produce ¼” crushed stone.

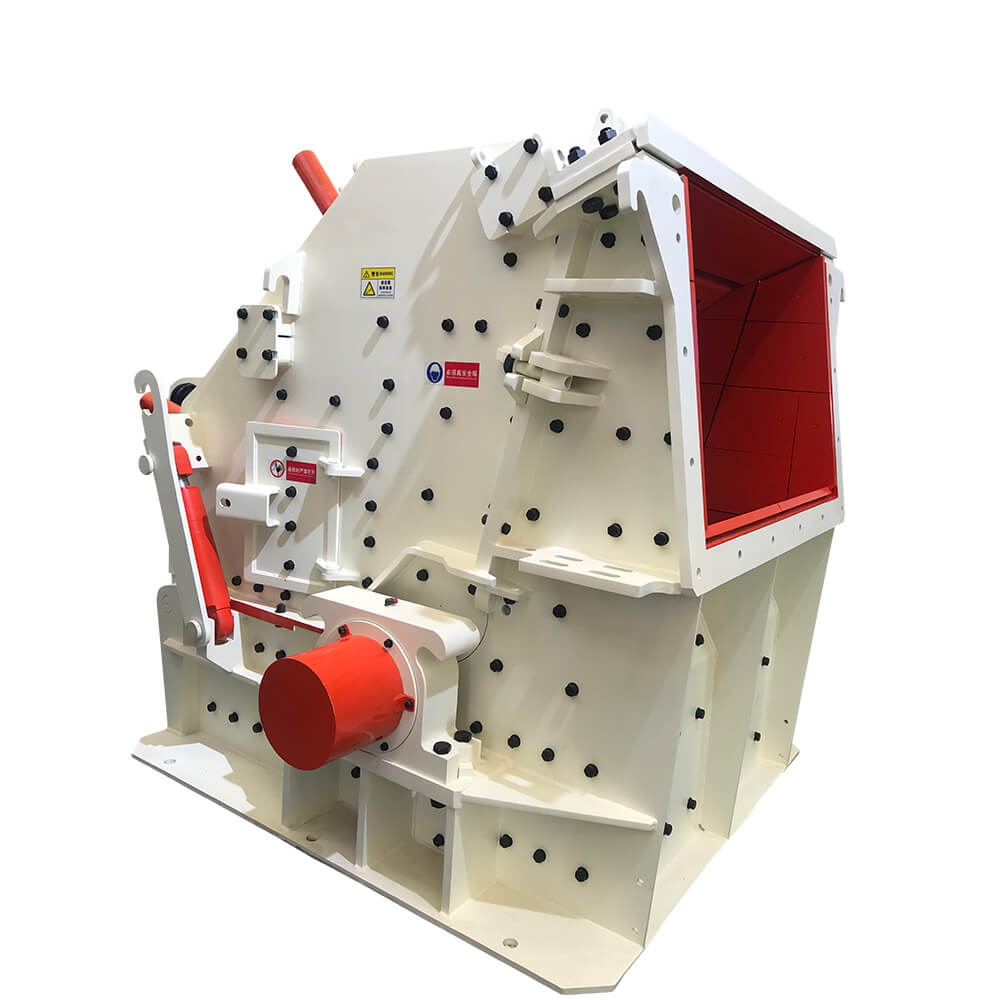

Cone crusher and counterattack crusher belong to medium crushing equipment, which can directly produce 5-10mm stone. The cone crusher breaks high hardness materials without pressure. The particle size of the finished material is between 3-15mm, which is convenient to adjust and has high output, but the price is slightly expensive; The impact crusher has good particle shape and high-cost performance.

Impact crusher, counter roll crusher, and high-yield fine crusher are fine crushing equipment, which can produce qualified HPB stone. Among them, the impact crusher has high output, good grain shape of finished products, and high price; The grain shape of the finished product of the fine crusher is good, but there are too many vulnerable parts, so it is not cost-effective to use; The roller crusher has the advantages of affordable price, simple operation, durable wearing parts and more choices by users.

The mobile crusher can be directly driven to the site for operation and can adapt to complex sites. One machine can complete a whole production process, which is relatively fast and convenient. The output is between 20-400 tons/hour. The configured crushing equipment can also be switched at will, with a wide range of choices and more choices by users.

The micro powder mill is mainly composed of the main machine, blower, ultra fineness analyzer, finished cyclone powder collector, bag dust collector, and connecting air duct pipe. According to the needs of users, it can be equipped with auxiliary equipment such as an elevator, storage bin, electric control cabinet, powder feeder, and crusher. In the micro powder grinding chamber, the grinding roller assembly is suspended on the grinding roller hanger through the cross arm shaft. The grinding roller hanger is fixedly connected with the main shaft and the blade holder. The pressure spring is tightly pressed on the outer end of the cantilever of the grinding roller bearing chamber by the tension rod. With the cross arm shaft as the support point, the grinding roller is tightly pressed on the inner circular surface of the grinding ring by the spring pressure. When the motor rotates through the transmission device, the blade installed on the blade holder rotates synchronously with the grinding roller, The grinding roller rotates around itself while rolling on the inner circular surface of the grinding ring. The analyzer drives the impeller of the analyzer to rotate through the motor transmission device, and the speed adjustment of the analyzer determines the powder fineness.

In conclusion, impact crushers, counter roll crushers and mobile crushers are better equipment for producing 5-10mm crushed stone.

How to Choose The Manufacturer of Stone Crusher?

There are so many manufacturers of stone crushers. The quotation given by each manufacturer is different, even very different. Which manufacturer is reliable? If you want a stone crusher with good quality and low price, come to Eastman crushing and have a look. The choice of machine mainly depends on three points: quality, price, and after-sales.

Quality: the core components of the Eastman crushing HPB stone crusher are made of high-performance wear-resistant alloy materials, which have high wear resistance and save the use cost. The finished HPB stone produced has better quality and high market selling price, which can bring greater benefits to users.

Price: the rigorous production process, automatic production equipment, and the direct selling method of manufacturers make Eastman crushing relatively low cost on the basis of ensuring product quality. In addition, it adopts the marketing method of small profit and quick turnover. It is positioned as an intermediate product in the market and has high-cost performance. This is also the reason why many customers choose Eastman crushing.

After-sales: Eastman crushing will send professional engineers to guide the installation on-site when users install the equipment, train the operation until users can operate independently, and train the equipment performance, basic operation methods, and troubleshooting, so that users can use it more easily. In case of equipment failure in the later stage, the manufacturer is on standby at any time, replies quickly in a short time, and arranges special personnel to solve it on site.