Tower Type Sand Making Machine

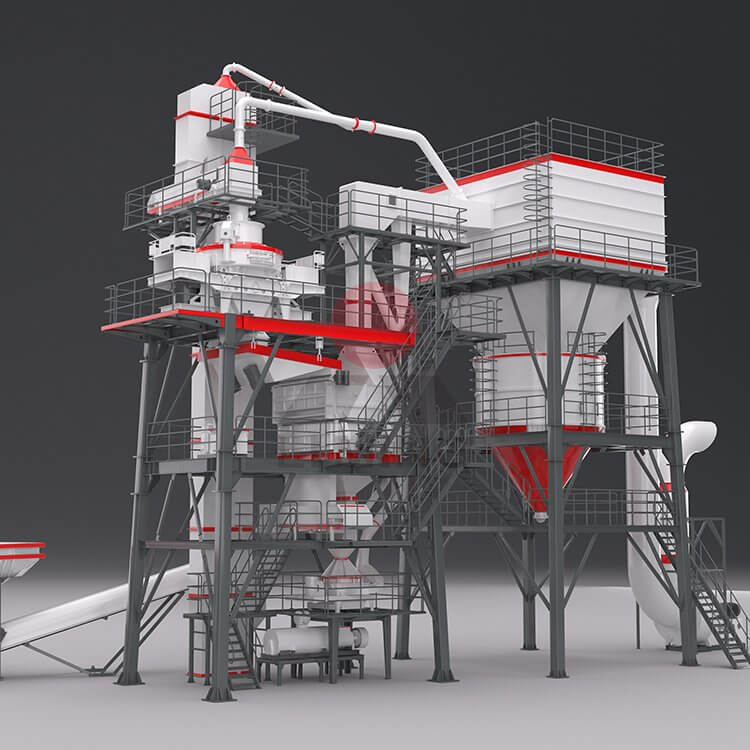

The tower-type sand making machine, also known as vertical sand making machine, is developed in recent years and the introduction of high-efficiency sand production equipment. As the name suggests, tower-type sand making machine is based on the steel structure of the steel structure to the combination of the floor-style portfolio, the entire system includes high-performance centrifugal impact sand making machine, grading sieving module, stone powder blending module, environmental protection dust collector Modules, centralized control system, is a complete set of the dry sand production system.

China’s concrete consumption is close to 60% of the world’s output. As one of the most important raw materials for concrete, the aggregate consumption is huge with an annual output of more than 10 billion tons and an industry scale of more than 500 billion yuan. In recent years, with the acceleration of infrastructure construction such as transportation hubs and urban construction, the demand for construction sand and gravel is still increasing.

However, over-exploitation of natural gravel led to a shortage of resources and the ecological environment was severely damaged. In addition, the traditional gravel aggregates have a small scale, backward equipment, large land occupation, large pollution, low resource utilization, and poor quality of sand and gravel, which are inconsistent with the commercial requirements of “sustainable development” and concrete gravel of the country. The vigorous development of the sand-making field also puts forward higher and more diversified requirements for the sand-making process and sand-making equipment. This is to mention the tower sand making process and tower sand making equipment.

What is a Tower Type Sand Making Machine?

Tower type sand making machine, also known as aggregate optimization system or tower type sand making building, is mainly divided into working modules such as feeding, crushing, machine-made sand molding, grading adjustment, screening, sand powder separation, dust removal, transportation, electrical control, wet mixing and so on. It integrates sand making, particle size optimization, stone powder control, grading adjustment, water content control, and environmental protection. It is a set of vertical sand production lines.

What is The Process Flow of Tower Sand Making Machine?

The raw materials are transported to the bucket elevator through the conveyor and sent to the sand making machine through the elevator for crushing. The crushed materials enter the powder separation equipment and then enter the next layer of the vibrating screen. The returned materials enter the bucket elevator and sand making machine again through the discharge end of the vibrating screen for crushing.

What Are The Characteristics of Tower Sand Making Machine?

- Small floor area

The tower sand making machine is a vertical structure, and the whole space occupies a small area. - The finished product has good particle size and controllable gradation

The impact crusher used in the whole production line has a round particle shape and uniform thickness. In addition, the grading and stone powder content can be adjusted by adjusting the negative pressure and distributor settings. - Environmental protection, no dust

The whole production process is closed without considering the problem of powder overflow. In addition, powder dust removal equipment is also installed, which can provide a double guarantee.

Popular VU Tower Sand Production Line

VU dry sand making system adopts highly intensive tower type fully enclosed layout, integrating sand making, particle size optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment. It not only significantly improves the production efficiency, but also improves the grain size, grading, powder content, and other indicators of machine-made sand, so that the performance of machine-made sand is comparable to that of natural sand, creating new opportunities and values for the development of sand, cement, and concrete industry chain.

Scope of application: Sand making in mixing plant, dry mixed mortar, cement product factory, aggregate mine, large construction project, etc.,

Materials: Cheap and easily available tailings, waste materials, construction waste, stone chips, melon rice stone, etc.,

VU Tower Sand Making Process Flow

- The material is crushed by VU vertical shaft impact crusher, eliminating the needle-shaped material, removing the sharp edges and corners of the sand, so that the grain size reaches the required size.

- The crushed material is evenly transported to the mold-controlled sieve through the conveyor and vibrating feeder, the material is graded, and the grading of the sand is finely controlled. The unqualified material is returned to the sand making machine for crushing, and the excess stone powder is removed by a dust removal collector.

- Separate the qualified finished product into the humidifying agitator, and then mix and wet to control the moisture content of the finished sand to further ensure the quality of the finished sand.

- The excess stone powder produced in the production is collected by the pulse dust collector, sent to the finished material tank by the pneumatic conveying system, and then packaged and transported.

The advantages & Features

- The sand is full and round.

The finished sand is fully crushed and polished through three optimization functions of Vu impact breaking, high-frequency “stone beating stone” impact shaping, high-speed grinding, and waterfall grinding brush of particle optimizer. The sand is full, the surface is round and uniform in thickness, the grading, particle shape and powder content of sand are more reasonable, the proportion of 0.15-0.6mm fine sand is greatly increased, the proportion of 2.36-4.75mm coarse sand is decreased, and the powder content is between 3-15%, which can be adjusted arbitrarily. - Adjustable and high efficiency

Due to the existence of the model-controlled screen of the integrated screening machine, it has the functions of vibration screening, material separation and air powder selection at the same time. On the premise of not replacing the screen, the grading of finished sand and the content of stone powder can be adjusted at any time by adjusting the negative pressure and the setting of the distributor, and the screening efficiency is high. - Environmental protection indicators meet the standard.

The negative pressure dust collector is adopted, combined with the sealing operation in the whole process and closed environment, to ensure that there is no dust on the site in the whole transportation process from the powder ore bin to the powder tank truck, while the dry production does not need water washing, and there is no problem of sewage and sludge treatment in the production process. All environmental protection indicators meet the national standards. - High degree of automation

With an integrated electric control system, the operation of the whole set of equipment can be monitored and adjusted online, and one key start and stop, abnormal alarm, emergency stop, automatic stable operation parameters, etc. can be realized to ensure the smooth and stable quality of finished sand and the production capacity of the production line.