Artificial Sand: Dry And Wet Sand Production

The maturity of sand making technology provides people with more choices, not limited to but including equipment, process, mode and so on. At present, the mature sand making processes in the market include wet sand making and dry sand making, which have their own advantages and disadvantages. Therefore, it is suggested that customers should pay attention to local conditions when choosing, so as to obtain higher profits. Today we mainly talk about dry sand production and wet sand production.

Dry Sand Production

What Is Dry Sand Making?

Dry sand production is not limited by the environment, and it can be produced even in areas with an extreme shortage of water resources. The dry sand process is to remove powder by powder concentrator, and the content of stone powder can be adjusted according to the demand, so as to meet the standard of building sand. The dry sand separation accuracy is high, and the particle size of the finished product can be controlled above 90um, which is suitable for the production of manufactured sand at all levels.

Dry Sand Making Process

Raw materials – vibrating feeder (waste removal) – coarse crushing – medium and fine crushing – screening (screening large aggregate) – sand making – screening (screening small aggregate) – dust removal – powder selection – finished sand

The raw materials fall from the silo to the vibrating feeder and are evenly and continuously fed to the jaw crusher for crushing after the simple screening, and then sent to the cone crusher until they are treated to a size of about 50mm and discharged.

It is transported to the sand-making machine by the conveyor, and then discharged and transported to the screening machine after full and effective crushing. The finished products with qualified particle size will be transported to the transfer pile, and those exceeding the screen specification will be returned to the sand making again.

The qualified materials will enter the powder concentrator for dust removal, and finally the finished sand.

Process Advantages

The finished product has low water content and adjustable stone powder gradation. It can be configured with high-strength concrete, used for Subgrade cushions, or as the raw material of slag brick. It has a high utilization rate, is not affected by seasons, and there is no need to treat sewage in the follow-up.

Process Disadvantage

The requirements for the content of soil impurities of sand and gravel raw materials are high, and the cleanliness of finished products is low. If dust removal is not carried out, it will cause serious dust pollution.

Wet Sand Production

What Is Wet Sand Making?

The wet sand making process has a longer history than the dry sand making process. It is a sand making process to remove fine powder and impurities on the surface of machine-made sand by the sand washing machine (wheel or spiral). The wet sand making process is more suitable for places with heavy rain or rich water resources.

Wet Sand Making Process

Raw material – vibrating feeder (removing soil) – coarse crushing – medium and fine crushing – screening (screening large aggregate) – sand making – screening (screening small aggregate) – sand washer – finished sand.

The raw materials fall from the silo to the vibrating feeder. After simple screening and soil removal, the jawbone is still responsible for the coarse crushing process. The raw materials are treated to be about < 400mm, followed by cone crushing, which is responsible for crushing the stones to < 55mm.

After that, it is transported to the sand-making machine by the conveyor for sand-making operation. After screening the size and specification, the unqualified will be returned and broken again, and the qualified will be transported to the next process.

In the wet sand-making process, the sand washer is responsible for the final operation. After sufficient cleaning and dehydration, the finished sand will be transported to the material pile.

Process Advantages

The finished product has low mud content, high cleanliness, and a good appearance. It is a more ideal material for some large-scale construction projects, and there will be no large amount of dust during the whole production process.

Process Disadvantage

It needs to consume a large number of water resources. About 2-3.5m of water is required for one ton of sand and gravel. The recovery cost of discharged sewage is high, and fine sand is easy to be lost. In addition, the water content of finished products is high and the sediment yield is low.

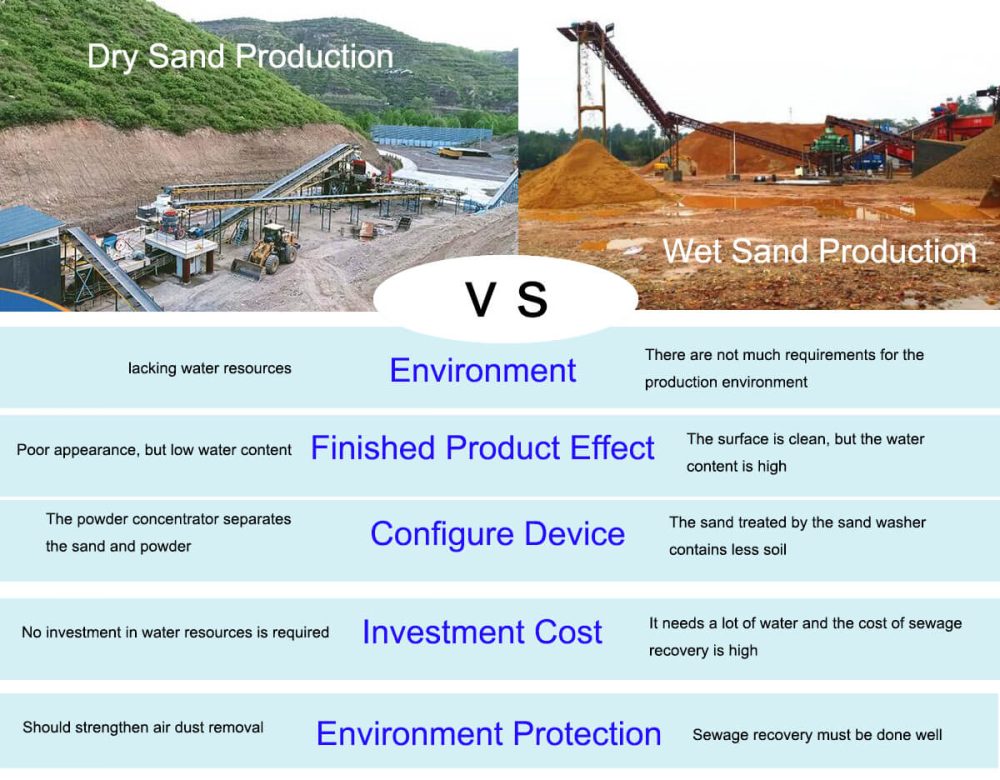

Difference Between Dry Sand Production and Wet Sand Making

1. Adapt to different regional environments

Dry sand is suitable for the natural environment in the north, where the weather is cold, dry and rainy, and there is a lack of water resources; Wet sand production must be carried out in the south, where it is humid and rainy and close to water resources.

Compared with wet sand making, dry sand has stronger adaptability to the environment and has no great requirements for the production environment.

2. The effect of producing finished products is different

The surface of the product produced by wet sand production is clean, but the water content is high, so it needs to be equipped with a dehydration device, with coarse fineness modulus and low sand output; The products produced by dry sand production are relatively not so clean and have the poor appearance, but they have low water content, good gradation, and high sand production rate.

3. The subsequent configuration equipment is different

The dry sand method is to achieve the powder removal effect of sand powder separation through the powder concentrator, and the separated dust will be recycled.

The subsequent configuration of wet sand making is a sand washing machine. The sand treated by the sand washing machine contains less soil and has a more round particle shape.

4. Different investment costs

Wet sand production requires a lot of water to wash sand, while dry sand production does not require investment in water resources, so the water investment cost is reduced to a great extent. In addition, the sewage recovery cost after wet sand washing is very high, and the loss of fine sand is also very large.

5. Different directions of environmental protection

Although dry sand making will save a lot of water resources, it will produce big stardust to pollute the air during operation, so it is necessary to strengthen air dust removal during dry sand making; Although there is no dust pollution in the wet sand making operation, a large amount of sewage will be discharged to avoid the pollution of mountains and rivers by sewage, so we must do a good job in sewage recycling.

Adjusting measures to local conditions is the key to the selection of sand making process. Whether a wet sand making method or dry sand making method is selected, the appropriate sand making method should be selected according to local conditions local environment, water resources, raw material cleanliness, sand fineness modulus, and other factors.