What Are The Cement Clinker Crushing Equipment?

Cement, as a necessary product in the infrastructure industry, must be understood by many friends. With the rapid development of infrastructure industry, the cement market is in short supply, which also leads to the phenomenon of setting up cement production plants on a large number of construction sites. In cement production, the first step is raw material crushing. What is the cement clinker crushing equipment today? What are the cement clinker crushers?

What are the cement clinker crushing equipment?

Cement crushing equipment mainly includes three types: coarse crushing equipment, medium and fine crushing equipment and fine crushing equipment. These three kinds of equipment are arranged in the three links of the cement crushing production process.

Cement coarse crushing equipment

It mainly refers to a jaw crusher, which is commonly used in cement clinker production. It is mainly used for the initial crushing of limestone, clay, and other raw materials. It is characterized by a large crushing ratio, mainly crushing large stones and high output.

Jaw crusher

Jaw crusher is one of the more suitable equipments for processing cement clinker. It mainly realizes the primary crushing processing of cement clinker, and the crushing effect is very good. The discharge particle size of the equipment is very uniform, which can meet the high crushing needs of many customers. It has strong comprehensive adaptability and a large material processing capacity.

In particular, the design of the jaw plate, the core component of the equipment, is very professional. The excellence of the jaw plate can not only improve the crushing ratio parameters of the equipment, but also help to improve the operation time and prolong the service life of the equipment. The overall satisfaction of customers with the jaw crusher is very high, Therefore, this is also the main reason why users choose this equipment to process cement clinker.

Cement medium crushing equipment

The counterattack break is used in the medium crushing link. The counterattack break is suitable for crushing brittle materials such as limestone. It is characterized by high production efficiency, low unit energy consumption, finer product particle size, and less wear.

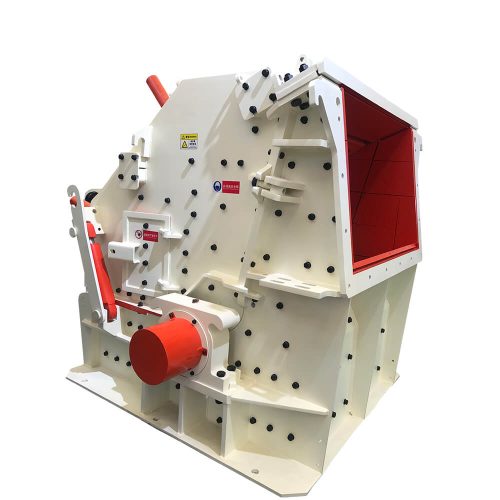

Cement clinker impact crusher structure

Cement clinker impact crusher (hereinafter referred to as cement clinker impact crusher) is mainly composed of machine body, rotor (several plate hammers parallel to the rotating shaft are installed on the rotor) and several arc impact plates in the upper space of the rotor. The rotor is directly driven by the motor to make it run at high speed.

Working principle of cement clinker impact crusher

After the clinker enters the machine body from the feed inlet, it falls onto the corrugated tray of the rotor. Because the rotor rotates with the main shaft at high speed, the materials on the tray and the rotor rotate with the main shaft at high speed, throwing the materials on the tray onto the impact plate. Due to the special structure of the impact plate, the materials are rebounded and move downward and inward, so as to enter the crushing chamber and be hit by the impact hammer. Due to the impact of the impact plate, It moves in a “Z” shape around the rotor until it is broken to a certain particle size and discharged into the cavity.

Performance advantages of cement clinker impact crusher

- The wear of easily worn parts is small and the utilization rate of metal is high. The wear of the plate hammer will only wear the front of the plate hammer, because when the rotor speed is normal, the feed will fall to the surface of the plate hammer, the back and side of the plate hammer will not be worn, and the bottom grinding rod is easy to replace, and the metal utilization rate of the plate hammer can be as high as 45% ~ 48%.

- It has strong processing capacity and can crush all kinds of coarse, medium and fine materials (cement clinker, granite, limestone, concrete, etc.) with feed particle size of no more than 500mm and compressive strength of no more than 350Mpa.

- Simplifying the crushing process can change the three-stage crushing into two-stage or one-stage crushing, and reduce the equipment cost of the concentrator. Equipped with multi-functional hydraulic station, it has the functions of hydraulic high-speed discharge gap, stable vibration reduction of counterattack plate and automatic opening of machine body.

- The discharge port is easy to adjust and the product particle size is good. By adjusting the gap between the rotor and the impact plate, the size of the discharge port can be adjusted, and the particle size of the crushed material is uniform, cubic, large output and high efficiency.

Cement crushing equipment

Of course, the impact crusher is used for fine crushing. It can grind the cement material to a particle size of 0-5 mm. It is characterized by good molding effect, reasonable stone grading, less dust and low noise.

Characteristics of impact crusher

- There are rotating working parts in the machine – rotor.

- Crushing by the impact of the working mechanism on the blocks or the blocks impact each other.

- Mainly use the function of high-speed impact energy.

- Break the material along its fragile surface in a free state.

- It is especially suitable for crushing brittle materials such as limestone.

Another Cement Crushing Equipment

Cone crusher is advanced crushing equipment in the mining field. Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation. In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further simplified, which provides a theoretical guarantee for reducing the difficulty of using the equipment; Wide range of particle size adjustment.

This advantage further improves the comprehensive utilization value of the cone crusher, further widens the use range of materials, and can also meet the various use needs of customers in terms of discharge particle size; Stable operation: the operation state of the new generation of cone crusher is more stable, which makes the reliability of the equipment rise steadily and plays a greater role in improving the production efficiency of the equipment.

With the continuous progress of science and technology, the roll crusher has made a great breakthrough in function, which has attracted extensive attention in the industry. The structural design of the equipment is very special. The traditional crushing equipment generally adopts a single motor for startup and operation, while the roll crusher adopts a double motor startup mode, which can not only effectively reduce the startup time of the equipment, At the same time, it can also improve the starting efficiency of the equipment. When the equipment completes the starting work, the equipment will automatically switch to the operation mode of a single motor, which can achieve the effect of energy conservation and environmental protection. At the same time, the operation noise of the equipment has been well suppressed here. It is not difficult to find that the counter roll crusher has a very good effect on the processing and production of cement clinker.

The above equipment can process cement clinker, and each equipment has its own characteristics and advantages. Eastman crushing is a large mining equipment manufacturer in China. Our equipment has excellent quality and long service life, and can meet the actual purchase needs of customers in terms of price formulation, and the service quality can also meet the customer satisfaction standard.