7 Differences of Jaw Crusher

As a widely used coarse breaking equipment, jaw crusher has a development history of one hundred years. At present, there are some differences in the structure, shape, design and materials of jaw crushers in the market. Today, we will sort out and analyze the jaw crusher from seven aspects: crushing chamber, frame, discharge port adjustment, motor installation, bearing, start and control, speed, and stroke.

1.Crushing Chamber

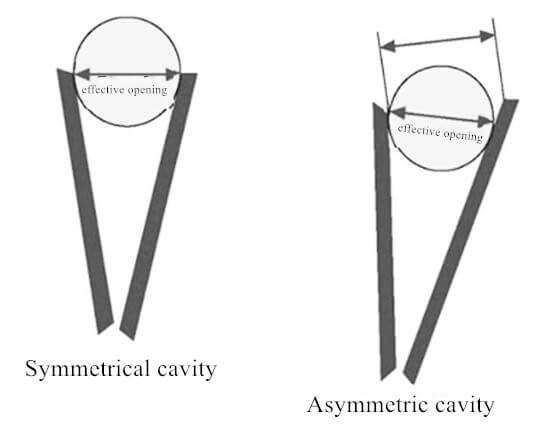

The traditional crushing cavity is a “right triangle”, the fixed jaw is a straight edge and the moving jaw is a bevel edge; The new crushing cavity is a “symmetrical isosceles triangle”. The allowable feed particle size of this cavity crusher is 5% larger than that of the traditional crushing cavity under the condition of the same inlet size.

The relationship between the size D of the feed port of the traditional crusher and the maximum feed particle size f is f = 0.85d, and the “symmetrical isosceles triangle” crusher is f = 0.9d.

The included angle or “meshing angle” between the moving jaw and the fixed jaw is an important parameter to measure the performance of the crusher. The smaller the included angle is, the greater the crushing force is, and the stronger the performance and processing capacity of the crusher with the same inlet size are.

The included angle of foreign advanced Hubei crusher is between 18 ° – 21 °, and that of domestic traditional PE crusher is between 21 ° – 24 °.

The crusher with a small meshing angle bears a large crushing force, so it has high requirements for the manufacturing and processing of the body, shaft, and bearing.

2.Frame

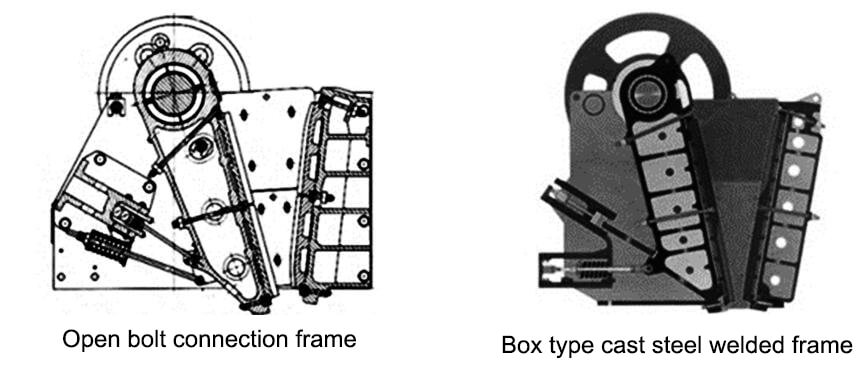

Jaw crusher frame has various structural forms, including welded frame, bolted frame, open frame and box frame.

3. Ore discharge opening adjustment mechanism

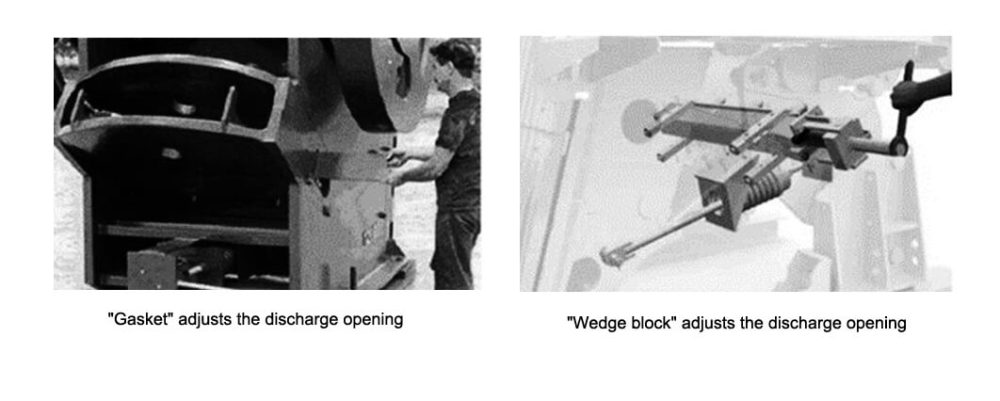

There are many kinds of adjustment mechanisms for jaw-broken ore discharge opening, and the more common ones are “gasket” adjustment and “wedge block” adjustment. The “gasket” is convenient and reliable to adjust and easy to manufacture; “Wedge block” is easy to adjust and operate, but its reliability is not as good as the “gasket” type.

In recent years, a “hydraulic cylinder” has been developed to replace the elbow plate and ore discharge port adjustment mechanism. This crusher has obvious advantages in the mobile crushing station.

4.Motor installation type

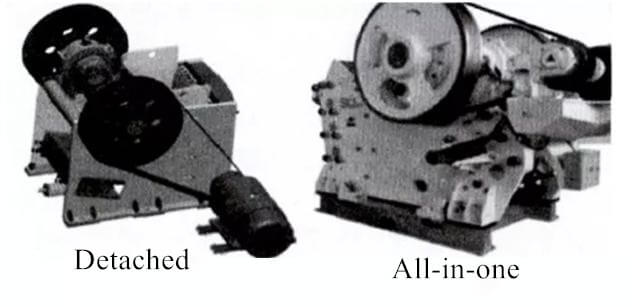

There are two ways to install the motor:

One is that the motor is placed on the crusher frame (integrated type) and driven by a triangular belt. The crusher is generally elastically connected with the foundation by rubber gasket;

The other is to install the motor on the foundation (independent), and the crusher is required to be connected with the foundation bolt.

The former installation has little disturbance to the foundation, but due to the limitation of the distance between the motor and the crusher pulley, the belt wrap angle is small. Therefore, multiple V-belts are required to meet the requirements of functional transmission. In addition, the quality of the motor is also required to be reliable to avoid insulation damage during motor vibration; When the motor is installed on the foundation, the crusher has great disturbance to the foundation and high requirements for the foundation, which increases the cost of the civil structure of the foundation.

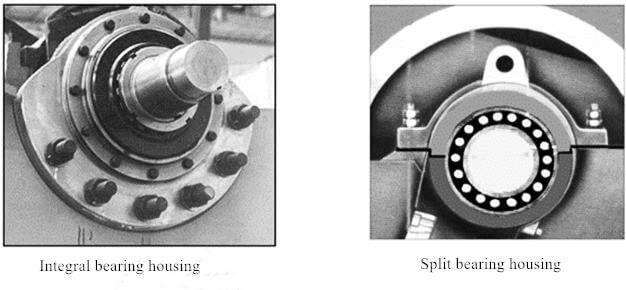

5.Type of bearing and bearing seat

Bearing is the core component of a jaw crusher, with high value and high reliability. Once there is a problem, the maintenance cost is high and the maintenance time is long. Therefore, the design and manufacturing requirements of bearing and bearing seat related components are strict.

Double row tapered roller spherical bearings are generally selected for bearings. For frame bearing seats, some choose integral bearing seats and some choose semi-open bearing seats. Be extra careful when installing the semi-open bearing seat, otherwise, the bearing will be damaged due to uneven bearing force due to poor installation.

6.Start up and control

In general, the main motor can be started directly, electronic soft starter, and variable resistance.

Direct start is generally aimed at small-sized motors with small motor power and allowable power grid capacity.

Variable resistance starting is suitable for winding motor. Due to the large blocking torque of the winding motor, it is more suitable for the working condition of the crusher, so this starting method is more common.

Electronic soft start is configured for rat dragon motor. For the overall installation mode of the motor and the crushing frame, generally select the rat dragon motor. At this time, the start of the main motor is an electronic soft start.

7.Speed and stroke of crusher

The meshing angle, speed and stroke of jaw fracture affect each other.

The rotating speed is determined by the number of times the material is broken and the discharge speed through the crusher. The faster the speed, the better. The faster the speed is, the crushed materials will not be able to be discharged from the crusher before they fall and suffer crushing; The speed is too slow, and the materials are directly discharged from the crusher without crushing.

The stroke determines the breaking force. If the stroke is large, the crushing force is large and the crushing effect is good. The size of the stroke is determined by the crushing hardness of the rock. With the different heights of the crushing chamber of the crusher, the speed of the crusher changes accordingly.

With the development of crushing equipment technology and the acceleration of product upgrading, users should understand the characteristics of different types of products, understand the relative advantages and disadvantages, identify the brand and strength when purchasing equipment.

The jaw crusher of eastman can crush all kinds of materials with compressive strength not exceeding 250 MPa. It is widely used for the primary crushing of various ores and rocks in various fields such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry, such as limestone, iron ore, basalt, granite, etc.