Separation and Recovery of Stone Powder in Machine-made Sand

How to Solve The High Content of Stone Powder in Machine-made Sand?

The production of manufactured sand needs to go through many processes such as crushing, screening and sand making, which will inevitably produce a large amount of stone powder. An appropriate amount of stone powder can improve the strength of concrete and reduce the risk of segregation and bleeding of its mixture under the action of hydration. However, if the content is too high, it is not conducive to the bonding between aggregate and cement stone and will reduce the performance of concrete, Then, the powder output of the sand production line is too large. What should I do? What is the content of stone powder in sand? Is it a normal standard? How should the large content of stone powder be solved? Let’s take you to know more about it.

Standard for Manufactured Sand

Manufactured sand: rock particles with particle size less than 4.75mm made by mechanical crushing and screening, but excluding particles of soft rock and weathered rock.

Ultra fine sand: natural river sand with fineness modulus of 0.7-1.5 tested according to the method specified in < < building sand > > (GB / T 14684).

Mixed sand: sand mixed by machine-made sand and ultra-fine sand.

Manufactured sand concrete: concrete prepared with manufactured sand as fine aggregate.

Mixed sand concrete: concrete prepared with mixed sand as fine aggregate.

Plastic concrete: concrete with slump of 10-90mm of concrete mixture.

High fluidity concrete: concrete with slump of concrete mixture equal to or greater than 160mm.

Pumped concrete: the slump of concrete mixture shall not be less than 100mm and the concrete shall be pumped for construction.

How much stone powder content should be controlled in machine-made sand?

Stone powder in machine-made sand refers to particles with particle size less than 0.075mm. In our production process, because the sand making machine is metal crushing, it is inevitable that fine powder will be produced in the crushing process of stone. If the manufactured sand contains an appropriate amount of stone powder, it is beneficial to its use. The general requirements for the content of stone powder in manufactured sand are: class I sand ≤ 1.0%, class II sand ≤ 3.0%, and class III sand ≤ 5.0%.

The stone powder content grades of manufactured sand are 3%, 5% and 7% respectively, which is relatively relaxed by 2% compared with the mud content of natural sand. In order to prevent the machine-made sand from being mixed with excessive soil due to various factors in the mining and processing process, the machine-made sand used in the construction sand must pass the inspection of methylene blue MB value, and strict inspection and test shall be carried out on the site when the sand materials leave the factory (site) and construction.

The content of qualified manufactured sand and stone powder passing the MB value inspection of methylene blue shall be controlled by 3%, 5% and 7%. For the inspection results of methylene blue value, the stone powder content of unqualified machine-made sand is strictly controlled at 1%, 3% and 5%, so as to avoid the adverse impact on concrete due to the high stone powder content of machine-made sand.

In terms of use, the content of stone powder in C30 concrete is 10 ~ 15%, and that in C50 concrete is 5 ~ 10%.

When the content of stone powder in manufactured sand is different, the use scenarios are different. If the content of stone powder is too high, it still needs to be improved through certain technical methods.

| Concrete | ≥C60 | C55-C30 | ≦C25 |

| Stone Volume Content | ≦5.0% | ≦7.0% | ≦10.0% |

| Needle and Flake Particle Content | ≦8% | ≦15% | ≦25% |

| Sediment Percentage | ≦0.5% | ≦1.0% | ≦2.0% |

| Clay Content | ≦0.2% | ≦0.5% | ≦0.7% |

How to deal with the high content of stone powder in machine-made sand?

- The feeding size of machine-made sand shall be reasonable

The feeding size of machine-made sand materials shall meet the feeding standard requirements. If the size is too large, the sand making machine cannot be broken, which will increase the content of machine-made sand stone powder and damage the sand making machine in serious cases.

- Set screening link

The stone powder in the sand can be screened out by configuring screening equipment to collect and reuse the stone powder. Screen the excess stone powder content to improve the quality and quality of manufactured sand and make it meet the needs of construction sand.

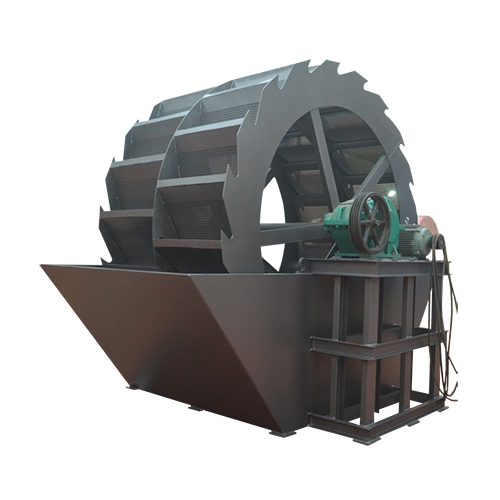

- Equipped with sand washing equipment

After the materials are crushed and made into sand, we can arrange sand washing equipment at the lower section of the sand making machine. The wheel sand washing machine equipment can clean the excess stone powder, soil and impurities in the machine-made sand, which can perfectly control the content of stone powder.

- Equipped with dust collection equipment

Equipped with dust collection equipment, the fan is used to absorb the stone powder, and the wind force is changed by adjusting the power of the dust collection equipment, so as to control the content of stone powder and make the quality effect of manufactured sand more stable.

Separation and Recovery of Stone Powder

As a stone resource, stone powder is also widely used, for example, it can be used in gypsum, coatings, cosmetics and other industries to create a lot of added value. Therefore, the separation and recovery of stone powder in machine-made sand is very important. This paper introduces two common methods of stone powder separation and recovery for dry and wet sand making processes for your reference.

1. Bag filter + sand powder separator

In the process of material crushing and screening, a large number of stone powder will be produced. The overflow and dispersion of these stone powder not only cause a waste of stone resources, but also cause serious pollution to the environment. Therefore, in the production process of stone, closed processing can be carried out, and then bag dust collector and sand powder separator can be configured to separate and recover it.

Principle: Based on the theory of hydrodynamics, the stone powder is divided into sand and fine powder through air separation in the suspended state, so as to achieve the separation of sand and powder.

Application: it can be used for the separation of super standard stone powder in the dry production process of machine-made sand and the secondary processing of stone powder in the stone production line. This separation method makes the fineness of machine-made sand easy to control and adjust, and the particle gradation more reasonable. It can be used together with various large and medium-sized sand production lines to meet the different needs of users.

2. Wheel sand washer + fine sand recycling machine

After the materials are crushed for sand making, we can arrange wheel sand washer equipment at the lower section of the sand making machine. The wheel sand washer equipment can clean the excess stone powder, soil and impurities in the machine-made sand, which has the characteristics of good cleaning effect, less loss of medium and fine powder and small water consumption.

The machine-made sand cleaned by the wheel sand washer can meet the standard of continuous grading. The sewage from the cleaning operation of the machine-made sand can be concentrated into the fine sand sedimentation tank for sedimentation. At the same time, the fine sand and stone powder in the sedimentation tank can be centrally recycled and utilized with the help of the fine sand recovery machine.

Supplement

The sand washing machine can wash away some small particles in the machine-made sand and some impurities, and the key is to control the stone powder content in the machine-made sand.

In actual production, the selection of sand washing equipment is different. Some sand and gravel factories use a vibrating screen as a sand washing machine to control the content of stone powder; Some use a separate wheel sand washer for stone powder control; Some think that the control effect of separate sand washing machine is not good, so they use wheel and screw sand washing machine to wash sand.

The above two methods can realize the separation, recovery and centralized utilization of stone powder and sand in the production process of manufactured sand. While protecting the environment and improving the grading quality of finished sand, it solves the recycling of waste stone resources, improves the economic and social benefits of stone production, and kills two birds with one stone.