Selection Of Quartz Stone Crushing And Grinding Equipment

Quartz stone is a type of new stone which artificially synthesized from over 90% of quartz crystals, resin, and other trace elements. It is a large-sized board made by special machines under certain physical and chemical conditions, and its material is quartz. Quartz is a mineral that can become liquid under heat or overwhelming force easily. It is also a common rock-forming mineral found in all three types of rocks. Because it is the latest to crystallize in igneous rock, it usually lacks a complete crystal plane and is filled in the middle of other rock-forming minerals that crystallize first. Quartz is widely used in industries like glass, casting, ceramics and refractory materials, metallurgy, construction, chemical industry, plastics, rubber, electronics, coatings, aerospace, jewelry, etc.

Features

1. Not easily damaged

Quartz stone has a quartz content of up to 94%, and quartz crystal is a natural mineral with a hardness second only to diamonds in nature. Its hardness can reach up to 7.5 Mohs, far more than sharp tools such as knives and shovels used in the kitchen, and will not be scratched.

2. Not easily contaminated

Quartz stone is a dense and porous composite material manufactured under vacuum conditions. Its quartz surface has good corrosion resistance to kitchen acids and alkalis. Liquid substances do not penetrate their interior. Liquid placed on the surface for a long time only needs to clean with clean water and detergent by a clean cloth. If necessary, a blade can scrape off any residue on the surface.

3. Not prone to aging

The quartz stone’s shiny and bright surface has undergone more than 30 complex polishing processes, which will not be scratched by knives or shovels, penetrated by liquid substances, and cause problems such as yellowing and discoloration. Daily cleaning only requires rinsing with water, which is simple and easy to operate. Even after prolonged use, its surface remains as bright as the newly installed countertop, no need for quartz stone maintenance and upkeep.

4. Strong fire resistance

Natural quartz crystals are typical refractory or fireproof material, with a melting point of over 1300 degrees Celsius. Quartz stone made of 94% natural quartz is flame retardant and will not burn due to contact with high temperatures. It also has high-temperature resistance characteristics.

5. Non-toxic and harmless

The surface of quartz stone is smooth, flat, and free from scratches. The dense and porous material structure allows bacteria to hide nowhere and can touch food directly, making it safe and non-toxic.

The Equipment for quartz stone crushing plant

- Vibrating feeder+jaw crusher

The first step is the feeding and coarse crush processing, mainly using equipment such as vibrating feeders and jaw crushers. After a simple screening of quartz stone raw materials, the vibrating feeder will continuously and evenly deliver them to the jaw crusher for rough crushing.

- Vibrating screen+cone crusher

The second step is the screening and intermediate crushing process, mainly using vibrating screens and cone crushers. The crushed coarse quartz stone will screen by a vibrating screen, and after the screening, the quartz stone that meets the particle size requirements will transport by a conveyor to a cone crusher for secondary crushing processing. Those materials that do not meet the particle size requirements will return to the jaw crusher for further crushing.

- Sand making machine+sand washing machine

The third step is the sand-making and washing process, the machines are the sand-making machine and washing machine. The quartz stone after medium crushing becomes a small stone of less than 5cm, and then it is finely crushed by the sand-making machine to make sand. After making sand, it becomes quartz sand of different specifications; After the screening, the quartz sand is sent to the sand washer to clean the dirt, stone powder, and other impurities wrapped on the surface of the falling quartz sand to complete the sand making operation of quartz stone.

The above is a fixed quartz stone processing equipment, and there are currently new types of mobile quartz stone processing equipment on the market. The fixed sand-making machine will place on a movable frame (there are two types of mobile truck frames for choices: track type and tire type) and used as the main machine. The difference between mobile quartz stone sand-making equipment and fixed equipment is that mobile quartz stone sand-making equipment can move freely, and the transition is convenient, which adopts a centralized control system, with a higher degree of intelligence, which reduce labor costs.

In summary, the fixed quartz production line equipment has a larger production volume and good stability; The transfer operation of mobile quartz production line equipment is more convenient and is more suitable for situations where quartz raw materials are scattered. In short, whether it is fixed or mobile, as long as you choose one that meets the actual production needs.

Grinding equipment for quartz stone

We all know that the core equipment for powder production is a grinding machine, usually after the crushing stage. Above we introduced the information of the jaw crusher, and next, we will introduce the grinding equipment of quartz stone.

1. Raymond mill

Raymond mill is mainly located behind the cone crusher in quartz stone processing, used to achieve grinding production of quartz stone. This machine adopts a sealed production structure and has good environmental performance.

Advantages

- Strong wear resistance: The main components of the grinder are all made of high-quality castings, with fine craftsmanship, ensuring the durability of the entire equipment.

- Good environmental friendliness: During the entire grinding production process, there is a dust removal device, which reduces dust pollution and has good environmental protection.

- High fineness of the finished product: After being processed by the Raymond grinding mill, the fineness of the finished quartz stone powder is uniform, and the passing rate can reach 99%.

- Low investment cost: Compared to other grinding equipment, this Raymond mill integrates crushing, drying, grinding, and grading transportation. The system is simple and compact, and the working place covers an area of about 50% of the ball milling system. It can work outdoors, thus reducing some investment costs.

2. Ball Mill

A ball mill is a core equipment for crushing materials. Ball mills are suitable for grinding various mineral ores, which are widely used in industries such as mineral processing, building materials, and chemical engineering.

Advantages

- High grinding accuracy, one-time molding, uniform product fineness, and no impurities doped;

- We can select the material of the lining plate according to different production needs;

- Fully enclosed design to avoid dust pollution and improve the working environment;

- Install dust suction equipment at the inlet and outlet ends, and blow clean impurities with compressed air inside the motor to reduce dust volume;

- Large processing capacity, able to operate continuously for a long time without stopping, with obvious advantages in continuous operation;

- The ball mill barrel, lining plate, and the core parts inside the barrel are all with ultra wear-resistant treatment, which is more wear-resistant and more suitable for the high hardness of quartz sand. The feature of high wear resistance ensures a low failure rate and long service life of the quartz sand ball mill.

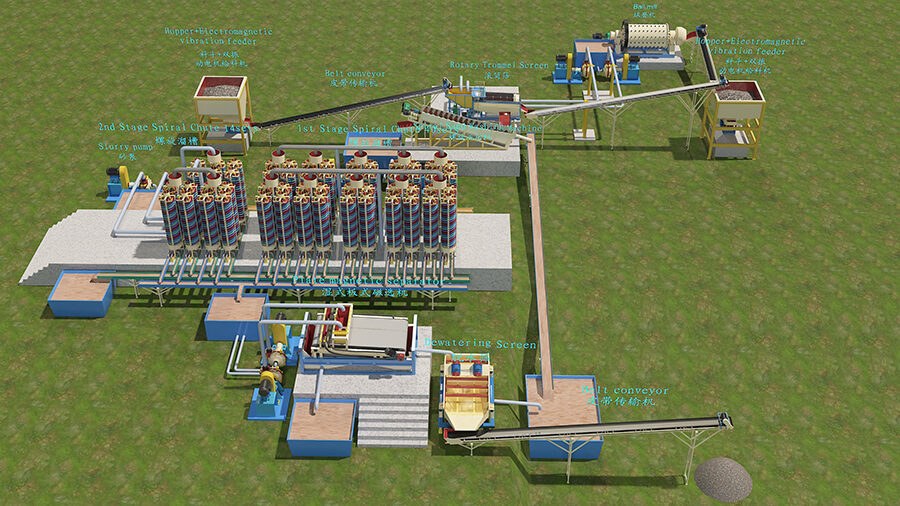

150tph Quartz sand processing plant

This setup is for the quartz sand process, the size range of the quartz sand is 0-10mm, and the machines are as below:

Hopper+electromagnetic feeder, belt conveyor, rotary trommel screen, the material larger than 0.5mm to ball mill, 0-0.5mm goes to spiral sand wash machine, spiral chute, slurry pump, wet plate magnetic separator, dewatering screen.

1. The hopper+electromagnetic feeder for feeding materials to the rotary trommel screen automatically, only need to load the materials to the hopper by truck or excavator or else as you want.

2. The rotary trommel screen is for washing the silica sand and separating the sand size 0-0.5mm to the spiral sand wash machine and the sand size larger than 0.5mm goes to the ball mill.

3. The ball mill is for grinding the sand size of more than 0.5mm size to 0-0.5mm, after grinding and selection, the sand goes to the spiral sand wash machine.

4. The spiral sand wash machine is for washing quartz sand and getting rid of the sticky clay in the silica sand, then to the spiral chute.

5. The slurry pump transports the clean materials to the spiral chute to separate the silica sand from other heavy materials.

6. The wet plate magnetic separator is to separate the magnetic minerals in the silica sand, making the silica sand purer.

7. The dewatering screen is for drying the silica sand and recycling the water.

Notes: if the materials are not much sticky, it will not need the spiral sand wash machine, and the quantity of the machines is for your reference, we will design according to your capacity.

There are two stages for the spiral chute. The middle concentrate from the first stage spiral chute will go to the second stage to concentrate again to make sure it is a higher grade, and also release the workload of the magnetic separator.

The above information shows quartz stone crushing and quartz sand grinding. We can provide various equipment for different raw materials crushing and grinding. Contact our professional engineers for a consultation! Get the factory prices!