Hard Rock Gold Processing Plant Solutions For Your Choices

Different raw ore property has various processing methods. When talking about the gold process, we should first investigate its form and reasons. Most people who study mineral processing do not study geology and mineralogy, but some knowledge of geology and mineralogy is the basic information for formulating mineral processing test schemes. Different research institutions form gold classification systems based on their mature research methods. We usually classify them into sand (alluvial) gold and rock gold from appearances. Sand(Alluvial) gold is formed of large-scale gold deposits with long-term water erosion and downstream wind erosion sedimentation. In different regions, it can be divided into gravity sand, flowing sand, glacier sand, and coastal (lake) sand. Alluvial gold beneficiation mainly involves gravity separation and enrichment.

From the perspective of geological reasons, rock gold divides into three categories: igneous rock, sedimentary rock, and metamorphic rock. Rock gold, also known as mineral gold, occurs in mines. Gold deposits are formed by underground hot springs gushing through thin cracks in rocks, usually sandwiched between quartz and rock. The reserves of rock gold are two to three times of sand gold, and the demand for gold mining equipment is also increasing. With the rise of gold prices, gold processing equipment is becoming increasingly popular. Let’s check the processing equipment and processing way of rock gold.

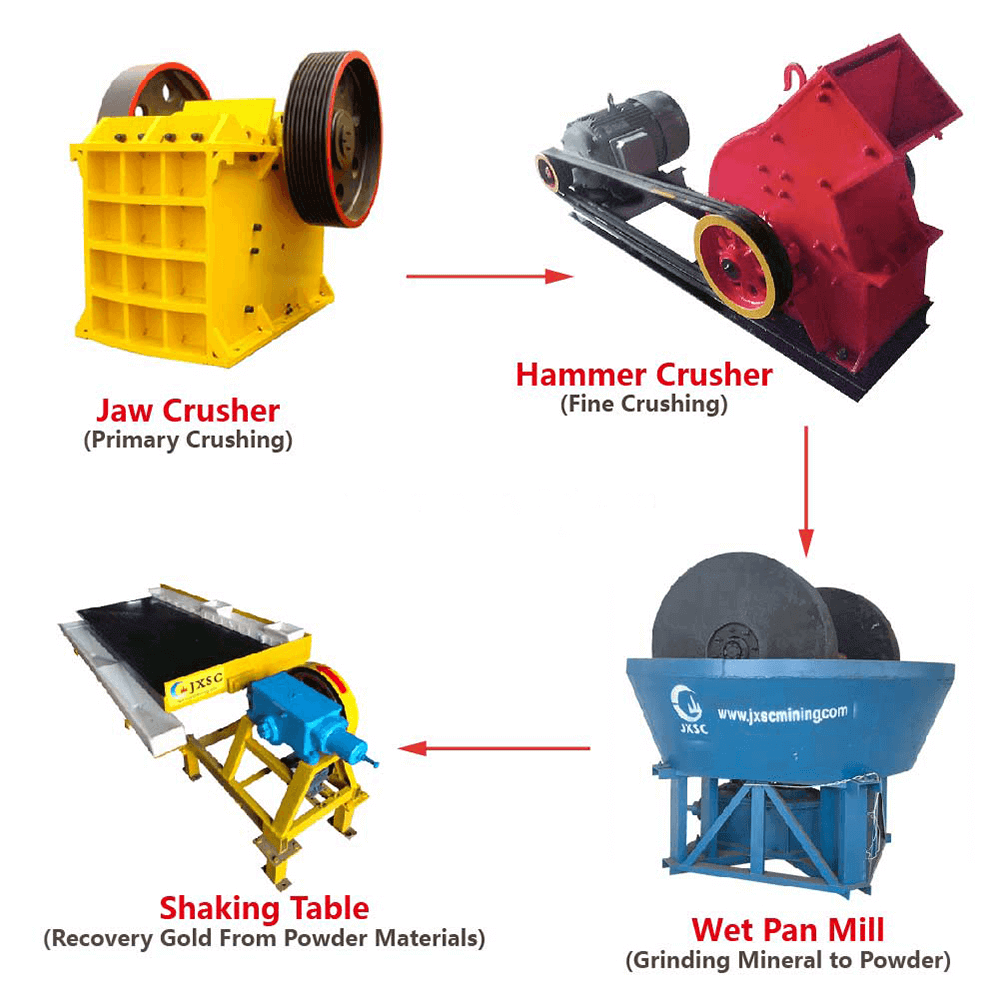

Rock Gold Processing Equipment

- Crushing Equipment

In addition to gold metal, gold ore also contains many other metal minerals, which are relatively complex in composition. Therefore, we usually choose stone crushers with good compressive strength and wear resistance to crush gold ore. The commonly used gold ore crushing equipment are jaw crushers and cone crushers. A jaw crusher is the primary crusher of gold ore and a cone crusher for the secondary crushing of gold ore. The specifications and models of gold ore crushers need to select based on material size and our requirements for production capacity.

- Grinding Equipment

The grinding equipment used in the gold ore processing plant includes ball mills, wet pan mills, and hammer crushers. The ball mill is suitable for grinding material to 200 mesh. Wet pan mill for grinding material to 0-1mm, hammer crusher crush material to 0-2mm. We will choose the machine depending on the actual situation.

- Upgrade Equipment

Gold ore upgrade equipment is the machine for purifying gold metals. The performance of gold ore beneficiation equipment directly determines the grade of gold extracted. The commonly used gold ore beneficiation equipment is flotation machines and jig separators. The flotation machine is for the gold ore flotation plant, jig separators are for gold ore gravity separation. The flotation machine and jig separator can be combined to purify gold ore together or separately. How to choose the right equipment? Based on our material situation and gold ore grade requirements for the product.

- Auxiliary Equipment For Gold Processing

In the gold ore processing plant, in addition to the crushing and grinding equipment mentioned above, we also need auxiliary equipment such as vibrating feeders, belt conveyors, vibrating screen, spiral classifiers, trommel screens, trommel scrubbers, thickeners, and dryers. The screening machines have three options: high-frequency vibrating screens, gold washing trommels, and circular vibrating screens.

Rock Gold Processing Solution

Different rock gold will release gold with different sizes. We can process the rock gold with various equipment in different budgets based on the output size with solutions as below.

- Release Gold Size 0- 2MM

- (1) For small rock gold processing capacities below 10TPH, We recommend vibrating feeder+jaw crusher+belt conveyor+hammer crusher+shaking table. This solution has the advantage of the lowest investment cost and a simple process.

- (2) For slightly larger processing capacity of 10TPH and above: Suggested process: vibrating feeder+coarse jaw crusher+belt conveyor+fine jaw crusher+belt conveyor+hammer crusher+centrifuge concentrator +shaking table

- Release Gold Size 0-1 MM

- Wet pan mill solution: under small processing capacity, vibrating feeder+jaw crusher+belt conveyor+hammer crusher+wet pan mill machine+shaking table; under large processing capacity, vibrating feeder+coarse jaw crusher+belt conveyor+fine jaw crusher+belt conveyor+vibrating screen+transfer silo+electromagnetic vibration feeder+wet pan mill machine+centrifuge+shaking table

- Ball mill solution: The simplest process suitable for a small processing capacity of 1-2TPH is vibrating feeder+jaw crusher+belt conveyor+hammer crusher+ball mill+shaking table. For medium processing capacity, the process is: vibrating feeder+coarse jaw crusher+belt conveyor+fine jaw crusher+belt conveyor+transfer silo+electromagnetic vibration feeder or pendulum feeder+ball mill+shaking table, high processing capacity of 10TPH and above,vibrating feeder+coarse crusher+belt conveyor+fine jaw crusher+belt conveyor+vibrating screen+transfer silo+electromagnetic vibration feeder or pendulum feeder+ball mill+centrifuge+shaking table

- Release Gold Size 200 mesh

- The crushing section is the same as the 0-1mm discharge situation, the difference is we need to add a spiral classifier or hydrocyclone to the production line after the ball mill for classification. Coarse particles return to the ball mill for grinding, and the overflow of 200 mesh fine particles enters the next processing machine. If customers are concerned about cost and limited space, choose Cyclone. The default standard configuration is a spiral classifier, which has a better classification effect and forms a natural closed circuit system with the ball mill.

- Flotation Gold Processing Plant

- Based on the crushing process with a ball mill, and spiral classifier or hydrocyclone to get 200 mesh material.

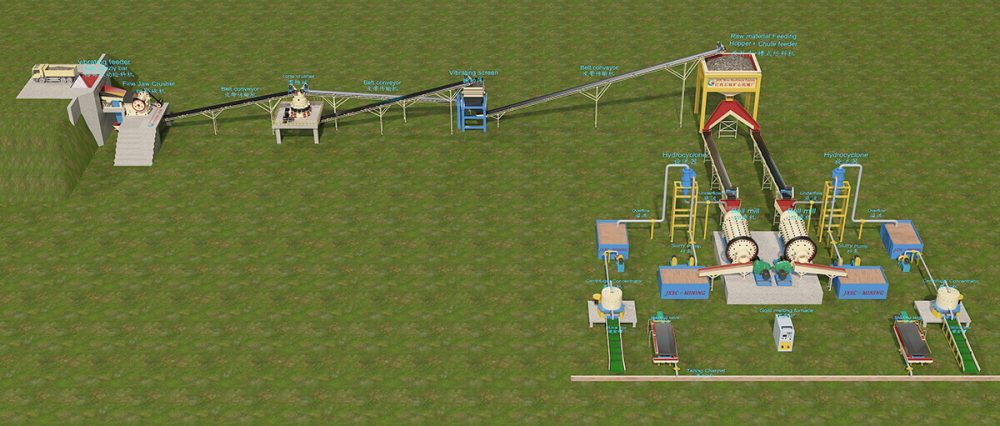

50tph Rock Gold Processing Plant

This setup is for a 50tph rock gold processing plant. The max input feeding stone size is around 200mm and needs to grind at 0.074(200 mesh) to release the inside gold.

- The raw materials feed into a vibration feeder. The vibration feeder with a grizzly bar. The grizzly gap with 100mm. Less than 100 mm down to the belt conveyor directly. More than 100mm goes to the jaw crusher for crushing first. The output from the Jaw crusher goes down to the same belt conveyor.

- The materials on the first belt conveyor transfer to a cone crusher for fine crushing, crushed at around 20mm.

- The output from the cone crusher goes to the vibration screen. The over-screen particles are more than 20mm back to the cone crusher for crushing again. The under-screen of less than 20mm goes to the next hopper by belt conveyor.

- Under the hopper, there is a small feeder for feeding the material more evenly.

- Then goes to the ball mill for grinding into fine powder :0-1mm

- The output from the ball mill goes to hydrocyclone for classifying. More than 0.074mm (Underflow) back to the ball mill for grinding again. The overflow goes to a slurry tank.

- The output goes to the gold concentrator for the first gold separation.

- The concentrate from the gold concentrator goes to the shaking table for fine gold separation and upgrades the recovery rate. The tailings go to the sluice box to get gold, in case of some free gold flow away.

Before we quote, we will need to know if it is sulfide-type or oxide-type rock gold, because different types of rock gold have various processing way. We also need to get the processing capacity (TPH) information of the gold processing plant, the max size of your rocks/ores, and the grind particle size of the rock gold to release gold. After getting this information we can suggest suitable equipment for you. Eastman Technology has a technical team to provide pre-sale and after-sale services. Welcome to inquire and get professional advice for the mineral processing plants and sand-making plant design and quotation!