Custom Mountain Sand Washing Plant & Equipment

Mountain sand is directly mined from the mountain. The composition of mountain sand is relatively complex, and generally contains a large amount of impurities such as soil and stone powder. Therefore, mountain sand is generally washed with water to obtain clean high-quality mountain sand. However, due to the different specifications and the high mud content, it needs to be cleaned to ensure quality, so how does the mountain sand turn into construction sand? The sand washer is indispensable, so which kind of sand washing equipment is easy to use?

use of Mountain Sand

According to the particle size and application field of mountain sand, it can be divided into three types: coarse sand, medium sand and fine sand;

- Coarse sand: 50% of the sand in the coarse sand has a particle size greater than 0.5mm. Coarse sand is mainly used in reinforced concrete structures;

- Medium sand: The particle size of medium sand is between 0.35~0.5mm. It is usually used in the construction of interior and exterior walls, ceilings and other floors, and can also be used for concrete of beams, columns, slabs and foundations;

- Fine sand: Fine sand generally refers to sand with a particle size below 0.35mm, and its fineness modulus is between 1.6 and 2.2. It is usually used for mortar for masonry and can also be used as filler;

Since mountain sand is a fragment formed by weathering for many years, such as: stones, fine sand, medium and small stones, etc. If it is not screened and washed, it is a worthless waste, but it can be transformed after being processed by the sand washing plant. It has become high-value construction sand, and it is this operation that has prompted the huge profits of the sand washing field! Artificial washing of mountain sand is actually very simple, just introduce a sand washing machine, which is cheap and has a high degree of cleaning.

Mountain Sand washing plant

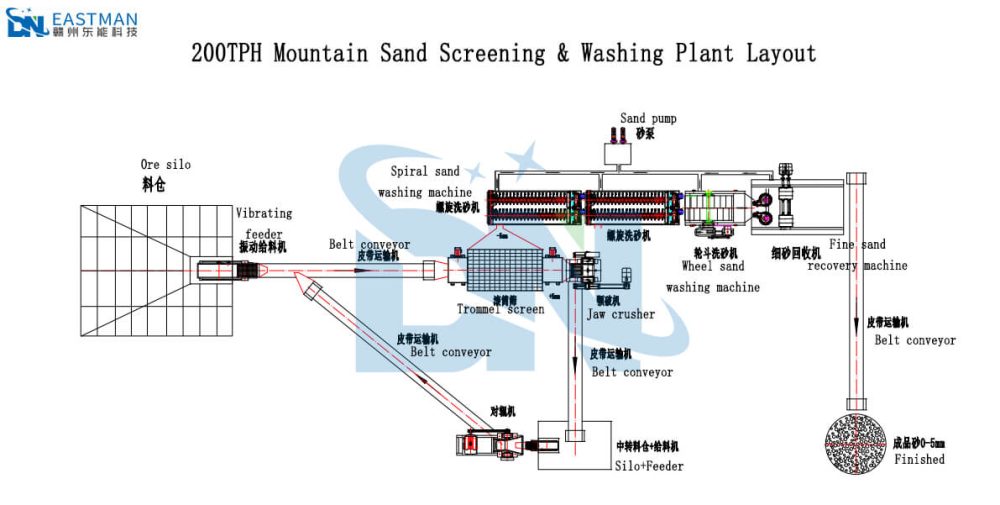

This setup is a 200tph mountain sand wash plant. It is configured with one set vibrating feeder DN4911, one set trommel screen GT2055, one set of fine crushing jaw crusher pe-250*750, two sets of spiral sand washer 2XL-915, one set of xs3610, 1 set fine sand recycling machine, 1 set of double roller machine 2pg800x600, 4 conveyors and two sand pumps.

Since there is much clay in the raw material, there are four-stage sieve washing procedures:

1. The truckload the raw material to the vibrating feeder, the stones larger than ≥210mm will be removed by the screen of the vibrating feeder, <210mm stone will be transferred to the trommel screen to wash and separate;

2. the -5mm sand will be sent to 2 stage spiral sand washer to wash, and then to the wheel bucket and washer wash again.

3. the +5-210 mm sand will be sent to a fine crushing jaw crusher to crush till 0-25mm, and then send to the double roller crusher to crush till 0-2mm. The 0-2mm material will be sent to the first conveyor to the trommel screen.

4. The output from the wheel bucket sand washer will be sent to the fine recycling machine to dewater. All tails of the trommel screen, sand washers, and fine sand recycling machine will be sent to the wheel sand washer to wash again and will be sent to the recycling machine to dewater. After dewatering, we can get the high-grade sand as required.

Mountain sand washing machine

At present, the commonly used sand washing machine equipment is the wheel sand washing machine, which has the characteristics of simple structure, easy operation, low failure rate and high cleanliness.

①Compared with the spiral sand washing machine, the price is cheaper, the investment cost is relatively low, and the material requirements for the sand washing production line are lower, and it can be competent for most sand washing production sites;

②The sand washing sewage generated in the production process can be recycled after being deposited in the sedimentation tank, which can effectively save water resources, reduce the cost of sand washing, and improve the income of sand washing;

However, some users will choose the spiral sand washing machine. Although it also has the characteristics of high cleaning degree, its water consumption will be relatively larger and the price will be more expensive.

When the wheel sand washing machine is working, the sand and gravel enter the washing tank from the feeding trough, and the sand and gravel roll and grind each other under the drive of the impeller, thereby removing the impurities covering the surface of the sand and gravel, and at the same time destroying the water vapor layer covering the sand, so as to prevent Good for dehydration. At the same time, add water to form a strong water flow, take away impurities and foreign objects with small specific gravity in time, and discharge them from the overflow washing tank to complete the cleaning effect. The clean sand and gravel are taken away by the blades, and the sand and gravel are poured into the discharge trough from the rotating impeller to complete the cleaning of the sand and gravel. The whole process can clean the mountain sand, and the effect is better.

Eastman Sand washing equipment Advantages

1. Multi-purpose machine

The structure is simple, the failure rate is low, the maintenance is convenient, and it has three functions of cleaning, dehydration and classification.

2. Large processing capacity

The processing capacity is large, the cleaning degree is high, the water consumption is low, the power consumption is small, and the loss of fine sand and stone powder is small.

3. Low accident rate

The impeller drive bearing assembly is isolated from water and water-receiving materials, preventing bearing damage from water immersion, sand and contamination.

4. Novel structure

Novel sealing structure, fully enclosed oil bath transmission device, and adjustable overflow weir plate ensure high performance of the equipment.

Mountain sand has a wide range of uses. For example, to set up a mountain sand washing plant, it is necessary to design a production plan reasonably according to the cost, production scale, operation, site and other conditions. However, due to the different processing standards of customers, there are many types and models of sand washing machines provided, which can meet the production needs of different enterprises. Eastman Technology has a technical team to provide tailor-made services, welcome online consultation, and get a design plant that suits you free of charge.