Custom Copper Refinery Equipment & Processing Plant

Copper is a metallic element, and pure copper is a soft metal, when it is first cut surface, the color is red-orange with a metallic luster, and the elemental color is purple-red. Due to its good ductility, high thermal conductivity, and conductivity, it is a popular material used in cables, electrical and electronic components, and building materials to form various alloys.

Copper ore, as one of the crucial minerals in metal minerals, undoubtedly promotes the overall progress of society through mining. Therefore, it is necessary to optimize the process flow. When selecting the copper ore processing equipment, it is essential to choose machines based on the actual functions of the copper ore processing equipment and the situation of mineral mining methods in recent years and try to use energy-saving and environmentally friendly new processes and new copper ore equipment to promote the efficiency of copper ore processing. So what equipment will be used in copper ore processing?

Copper Ore Processing Equipment

The feeding equipment before crushing are vibrating feeder, trough feeder, etc.

The vibrating feeder is widely used in the industries such as metallurgy, coal mining, mineral processing, and building materials. It can uniformly and continuously transport massive copper ore to subsequent crushing equipment and pre-screen the materials before crushing.

- Crushing equipment: The commonly used crushing equipment for copper ore selection mainly includes coarse jaw crushers, fine jaw crushers, cone crushers, etc.

- The jaw crusher is for coarse stone crushing applied in industries such as sand and gravel factories, metallurgy, mining, and chemical engineering. The feeding particle size reaches 1500 millimeters, and the discharge particle size is 10-350 millimeters. The capacity reaches 2200 tons per hour, and the compressive strength of the materials achieves 320 MPa. Large rock copper ore needs crush to smaller stones by using a jaw crusher to meet the medium crushing feed particle size requirement.

- The cone crusher is suitable for crushing medium and fine ores with medium to medium hardness and above, and the processing capacity is within 12-1000 tons per hour. It is suitable for crushing copper ore since it is with high hardness. After cone crusher crushing, get finished products with a size of 3-60 millimeters.

2. Grinding equipment: The grinding equipment for copper ore processing mainly includes ore dressing ball mills, dry ball mills, wet ball mills, grid ball mills, and ball mills, as well as pendulum feeders, electromagnetic vibration feeders, and belt conveyors for feeding ball mills.

- The function of a ball mill is grinding the material into fine particles of 0-200 mesh size to meet the conditions for the following flotation process. The feeding particle size of the ball mill is less than 20-25mm, and the discharge particle size is 0.074-0.89mm. It produces a capacity of 0.65-615 tons per hour, which is very popular in the industries like cement, silicate products, new building materials, and refractory materials.

3. Screening equipment: The commonly used screening equipment for copper ore selection mainly includes spiral classifiers, high-frequency screens, linear screens, vibrating screen etc. They are often equipped with ball mills to form a closed loop.

- The function of the vibrating screen is to screen and collect unqualified materials that meet the particle size of the next feeding step, and then send them back to the crushing equipment for further crushing until the particle size is qualified. Separate materials with different particle sizes send materials below 20mm into a ball mill, and materials above 20mm will go back to a cone crusher for further crushing.

- A spiral classifier is equipment used for particle size classification of ore slurry in the metal beneficiation process. The length of the water tank is 3000-1430mm, and the spiral diameter is 300-3000mm. The classification is based on the principle of different settling velocities of copper ore particles and associated gangue particles with a different specific gravity in the liquid.

4. Mixing equipment: The mixing equipment for copper ore selection is the mining mixing tank. Its function is to stir, add water, and reagents before the pulp enters flotation.

- The flotation process requires adding flotation agents to the slurry, so that mineral particles can better adhere to the bubbles generated by the flotation machine, float to the surface of the slurry, and then be collected by the flotation machine. The function of the stirring bucket is to stir the slurry, mix the agent and slurry evenly, and accelerate the reaction time of the agent.

5. Drying equipment: Drying equipment is for the dehydration treatment of copper ore concentrates. The commonly used dewatering and drying equipment for copper ore selection includes rotary drum dryers, thickeners, dewatering machines, etc.

- The copper concentrate collected by flotation has a high water content and not meet the usage standards, and requires dehydration. A dryer is a drying equipment specifically used in industries like mining, mineral processing, and chemical engineering. It can handle 1.9-76 tons of material per hour. In addition to copper concentrate, it can also apply to dry many other metallic and non-metallic minerals.

Copper ore process flow

- The ore first goes to a jaw crusher for coarse crushing, and after crushing to reasonable fineness, it is fed evenly into a ball mill through a hoist and vibrating feeder. The ball mill then crushes and grinds the ore.

- The ore ground by the ball mill enters the following step: grading. The spiral classifier uses the principle of different specific gravity of solid particles and different sedimentation rates in liquid to clean and classify ore mixtures.

- Due to the different magnetic susceptibility of the minerals, when the mineral mixture wash and grade pass through a magnetic separator, the magnetic substances in the mixture will be separated by magnetic and mechanical forces. After preliminary separation by a magnetic separator, the mineral particles feed into a flotation machine and add drugs based on different mineral characteristics to separate the required minerals from other substances.

- After separating the required minerals, due to their high moisture content, they need to be initially concentrated by a thickener and then dried by a dryer to obtain dry minerals. The grade of copper refined powder reaches 45%.

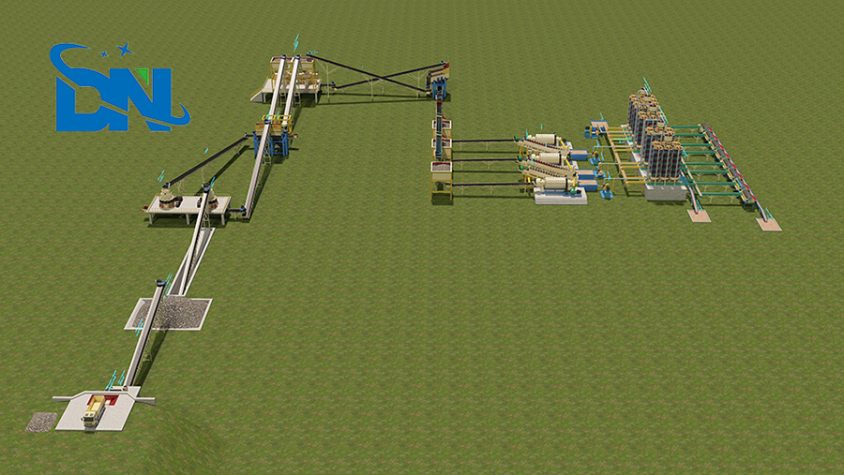

30TPH Copper Processing Plant

- First feeding mineral ore(30mm) to hammer crusher to break the rock stone.

- Then send the output stone(make a 10mm screen hole) to the hopper by belt conveyor. The materials below 10mm are selected by sieving,

- Through the electromagnetic vibration feeder to the ball mill.

- After the ball mill grinding, the material is pumped to the hydrocyclone group for particle size classification. The overflow 0-0.074mm is pumped to the 1st stage spiral chute separator with a slurry pump and the underflow >0.074mm returns to the ball mill for grinding again.

- The medium mineral after 1st stage will be pumped to 2nd stage spiral chute to separate again.

- Then the concentrates will send to the shaking table to concentrate copper and increase the copper recovery ratio to as high as possible. After getting copper concentrate ore from shaking tables.

- Tailing of spiral chute separator and shaking table sent to Tailing Channel.

- Send the copper concentrates to the magnetic separator to remove the iron.

Copper exists in different form of compound, such as copper carbonate, copper oxide, copper sulfide, etc. Different ore types will use various separation methods. Different sorting methods may use various beneficiation equipment, depending on the nature of the ore. Eastman Technology has a technical team to provide pre-sale and after-sale services. Welcome to inquire and get professional advice for the mineral processing plants and quotation!