Coarse Crushing Cone Crusher Or Jaw Crusher Is Better

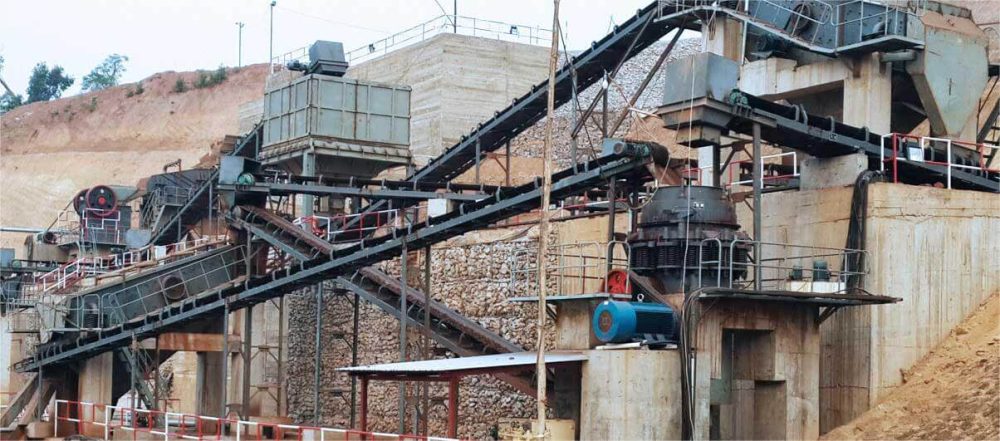

There are many kinds of crushers now, for example, in the field of mining machinery, ore beneficiation and crushing, ore grinding machine crushing stones, etc. all have the different crushing methods at the same time. There are also many kinds of ores, including metal and non-metal, with different hardness, but they all have a collective name of crusher. For example, jaw crushers are often used in coarse crushing, while cone crushers and impact crushers are often used in medium and fine crushing, and different models have different functions. Cone crushers are usually used as fine crushing equipment, but some models of cone crushers can also be used as primary crushers. So which one is better as a coarse crushing equipment, the cone crusher or the jaw crusher?

stone Crushing methods

There are three common crushing methods of stone crushing machines: crushing, splitting and breaking. Crushing is mainly used in stone crushing machines such as jaw crushers, cone crushers, and roller crushers. Hammer crushers and impact crushers, etc., mainly use impact.

- Crushing: The material is placed between two working surfaces, and after pressure is applied, the material is crushed due to the compressive stress reaching its compressive strength. This method is generally suitable for crushing bulky materials.

- Chopping: Place the material between a flat surface and a working surface with sharp edges. When the working plane with sharp edges squeezes the material, the material will split along the direction of the pressure action line.

- Bending: The material is crushed by bending stress.

- Impact crushing: The material is crushed by the impact force, and its crushing force acts instantaneously. It has high crushing efficiency, large crushing ratio and low energy consumption.

Coarse Crushing Equipment - Cone crusher

Cone crushers are widely used in stone production lines, gravel production lines, and gravel production lines. Cone crushers are divided into three types: coarse crushing, medium crushing and fine crushing. As far as the current situation of the crushing plant of the ore dressing plant is concerned, most of the medium crushing equipment adopts standard cone crushers. Most of the fine crushing equipment uses short-head cone crushers, which have almost been finalized.

1. Features: It is suitable for crushing all kinds of ores and rocks with medium and above hardness. It has the characteristics of reliable structure, high production efficiency, convenient adjustment and economical use. Its spring insurance series is an overload protection device, which can make metal foreign objects pass through the crushing chamber without harming the machine. Two sealing forms of dry oil or water are used to isolate the stone powder from the lubricating oil and ensure reliable operation. The ore application determines the form of the crushing chamber: the standard type is suitable for medium crushing; the medium type is suitable for fine crushing; the short head type is suitable for ultrafine crushing.

2. Advantages:

- Large crushing force, high efficiency, high processing capacity, uniform product size;

- Simple structure, balanced operation, convenient operation and adjustment, less downtime, low operating cost, convenient adjustment and economical use;

- Due to the reasonable material selection and structural design of the parts, the service life is long;

- Two sealing forms of dry oil or water are used to isolate the stone powder from the lubricating oil and ensure reliable operation;

Single Cylinder Hydraulic Cone Crusher

1. Features: It is suitable for secondary, tertiary or quaternary crushing of ore, rock or rock-based materials in large and medium-sized sandstone and sandstone processing enterprises. The crushing wall and the rolling wall of the eccentric pendulum complete the crushing process. Objects enter the crushing wall through the feeding hopper on the upper part, and are discharged from the lower part after being broken, and are collected and discharged in the hopper. It has the advantages of high output, low cost of use, compact structure, simple operation, less maintenance, wide application range and high utilization rate.

2. Advantages:

- Optimize the crushing frequency and eccentricity of the combination. And laminated crushing, so that the crushed material with the size of the discharge port can maintain a better product shape.

- The optimized liner design makes the unit steel consumption lower; laminate crushing and packed feeding make the equipment work rate higher.

- Only need button control, the hydraulic pressure can be used to realize the stepless adjustment of the discharge opening, and it can be carried out during the production process. Wear parts after finishing, no packing required during assembly.

- The single-cylinder hydraulic cone crusher adopts PLC control system, which can easily operate and control the crushing and reduce labor costs.

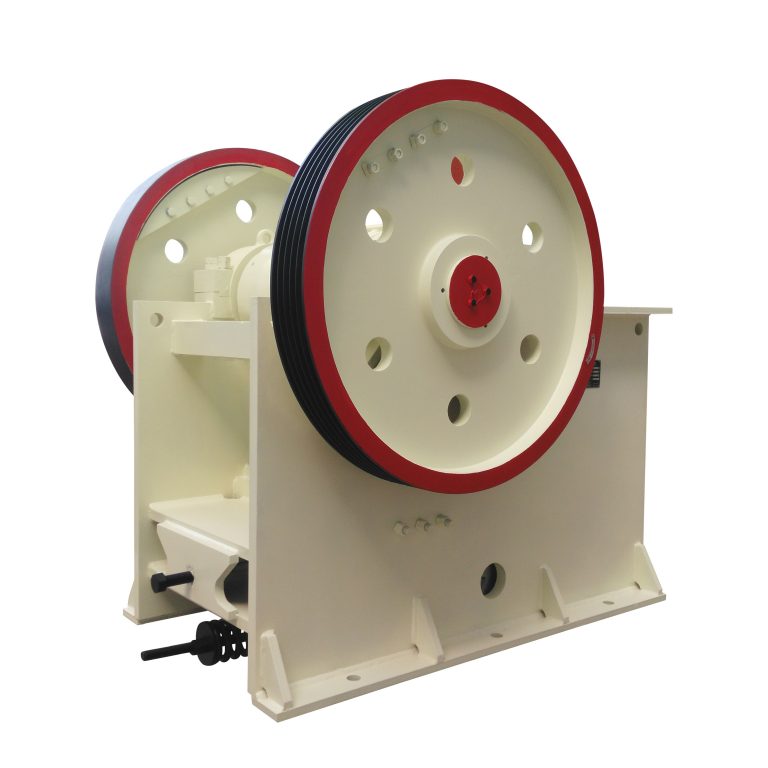

Coarse Crushing Equipment - Jaw crusher

Jaw crusher is driven by a motor, the eccentric shaft is driven by a V-belt and a sheave through the motor pulley. Make the movable jaw reciprocate according to the predetermined track to crush the material, so as to crush the material entering the crushing cavity composed of fixed jaw plate, movable jaw plate and side guard plate. It can crush various types of stones, such as the more common river pebbles and limestone, etc., can be used for primary crushing.

Advantages:

- The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output. It has a large crushing ratio and uniform particle size;

- Gasket-type discharge opening adjustment device, reliable and convenient, with a large adjustment range, increasing the flexibility of the equipment;

- The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small. The structure is simple, the work is reliable, and the operation cost is low.

- Equipment energy saving: 15% to 30% energy saving for a single machine, and more than double the energy saving for the system. The adjustment range of the discharge port is large, which can meet the requirements of different users; the noise is low and the dust is less.

There are many types of crushers, and the crushing methods are also different. It is determined which equipment to use according to the needs of customers and the nature of the ore. The cone crusher is suitable for coarse crushing of various hard and brittle materials with large output. The design of the deep V crushing cavity of the jaw crusher prevents the material from being blocked in the crushing cavity, which can effectively improve the production efficiency. Jaw Crusher and Cone Crusher, these two kinds of crushing machines have better particle shape, and the two complement each other. The specific choice of equipment mainly depends on the type and hardness of the material, the size of the finished product, the site and the actual demand, etc. Contact our professional engineers for consultation! Get the factory prices!