Machine-made Sand – Prospect, Using, Equipment & How to Buy

Recently, with the rapid development of the infrastructure industry, the demand for sand and gravel is increasing, and there is little river sand resources left. In addition to the national requirements for environmental protection, sand and gravel once appeared in short supply, resulting in the rising price of sand and gravel. Many people see this business opportunity and invest in sand and gravel industry one after another.

Is Machine-made Sand Profitable Under The New Situation?

According to the current development trend, machine-made sand is a profitable industry. Machine-made sand is made of pebbles, river pebbles, granite and other ores through a series of processing such as crushing, sand making and screening. Machine-made sand has convenient raw materials, low cost and simple sand making production process. Machine-made sand is a very promising industry. As long as it is properly operated, Don’t worry about no profit.

Why Can Machine-made Sand Replace River Sand?

At present, China’s large-scale infrastructure construction, such as highway, airport, railway, bridge and other industries have begun to use machine-made sand to replace river sand. It is not only now, but also a development trend in the future. So why can machine-made sand replace river sand?

- Cost problem

After years of exploitation, the reserves of river sand have been decreasing. Due to the excessive exploitation of river sand, the state has also begun to restrict the exploitation of river sand. Affected by environmental protection, the exploitation cost of river sand is getting higher and higher. Many people have abandoned the river sand Market and turned to speculative sand making market, and the market share of machine-made sand has also increased. - The quality of manufactured sand is more reliable.

There are too many uncontrollable factors and unstable quality of river sand. The particle size of machine-made sand can be manually controlled through the sand production line. Moreover, machine-made sand has good shape, high cleanliness and no impurities. Compared with river sand, machine-made sand is easier to control. Replacing river sand with machine-made sand is the trend of future development. The huge demand for sand and gravel in China’s construction industry further promotes the development of machine-made sand, and the development situation of machine-made sand market is very good.

What Equipment Does the Machine-made Sand Production Line Have?

The machine-made sand production line mainly includes a series of production links such as crushing, sand making, screening and sand washing. The equipment used include vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, sand making machine and sand washing machine. The machine-made sand production line is flexibly configured and can be configured according to the production needs of different customers.

Crushing equipment

Crushing equipment is mainly responsible for the crushing of ore equipment, mainly including coarse crushing equipment and medium crushing equipment. Jaw crusher is a common coarse crushing equipment, and cone crusher and impact crusher are common medium crushing equipment. The crushing equipment can process the ore to stones below 50mm, which is convenient for the shaping and processing of the sand making machine.

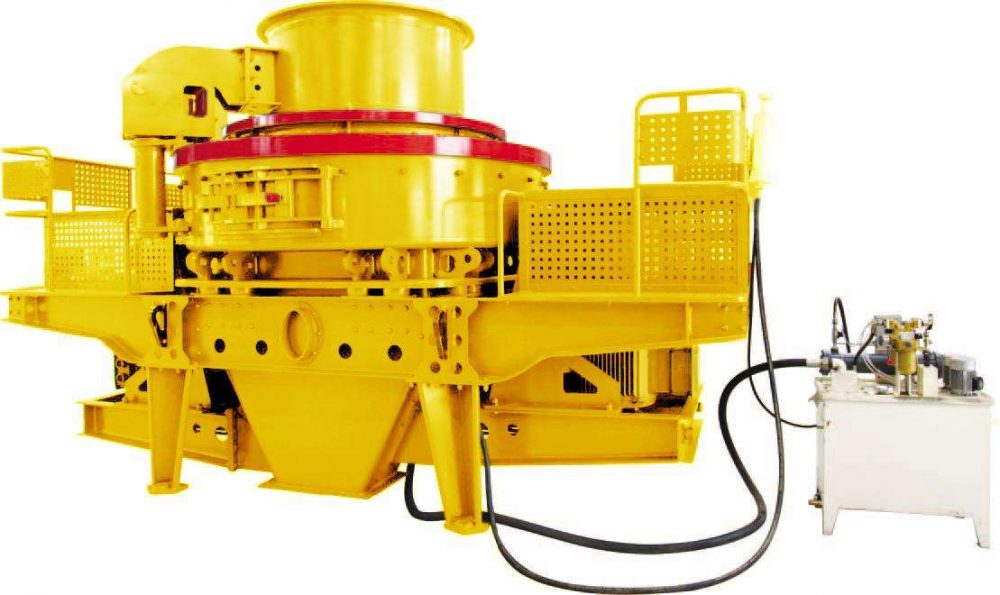

Sand making and sand washing equipment

Sand making and sand washing equipment are sand making machine and sand washing machine equipment respectively. Through the working principle of impact sand making, the sand making machine processes about 50mm ore to 0 ~ 5mm, 5 ~ 10mm and other specifications of sand. Then, the sand is cleaned by the sand washer equipment to wash away the impurities and dust contained in the sand and improve the quality of manufactured sand.

Auxiliary equipment

In addition to the main crushing, sand making and sand washing equipment, vibrating feeder, circular vibrating screen, belt conveyor and other equipment are also required to be responsible for feeding, screening and transportation respectively. These auxiliary equipment are essential for the machine-made sand production line.

Environmental protection and control device

In the production process of machine-made sand, in order to reduce dust and noise pollution and improve environmental protection effect, dust removal, noise reduction and humidification devices need to be equipped, and the conveying device can also be closed.

As an alternative resource of river sand, machine-made sand has occupied a more and more important position. With the improvement of the quality and quality requirements of machine-made sand, the gradation, powder content and particle shape of machine-made sand have also been paid attention to. How to buy high-quality sand making equipment and sand making production technology is particularly important.

How to Buy Sand Making Equipment?

- Understand your needs

Understanding our own needs and what our purpose is is a very key step, which can also help us select the appropriate sand making machine. - Understand the market

The market situation is changing with time. The market situation of the sand making machine is also different in different periods. For the sand making machine, we should understand the market reputation and price situation of the sand making machine, so as to help quickly find reliable manufacturers and understand the price positioning of the sand making machine.

About the market of sand making machine, we also need to understand the technology of sand making machine and the performance of sand making equipment, so that it is not easy to fall “pit” when we buy sand making machine; - Don’t be greedy for small things

When purchasing sand making machine, don’t be greedy for small and cheap. Generally speaking, the price of sand making equipment in the market changes in a range. If it exceeds this range, you should carefully consider whether the performance of the equipment can meet the production demand? Is the quality qualified?

We should also pay attention to discounts, promotions and other activities, which may be a trap to attract customers, so don’t choose to buy because the price is low. We must pay attention to whether the quality and performance of the sand making machine are qualified.

Eastmancrushing is a professional crushing machines manufacturer in China. We supply various of crushers to fit your different using. If you are finding crusher supplier, welcome to contact us.