Why Does The Sand-making Machine Sudden Stop?

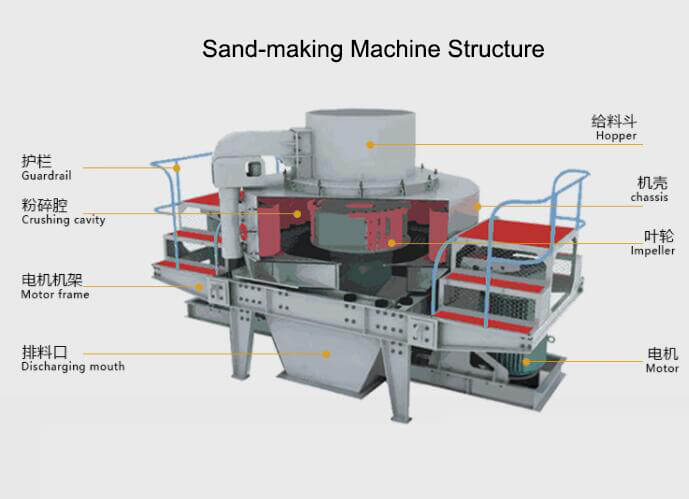

The sand-making machine is an important equipment in the sand-making process. Have you ever encountered such a failure when the sand-making machine suddenly stopped during the production process? The shutdown of the sand-making machine has a great impact on our production efficiency, so today we share several reasons and countermeasures for the sudden shutdown of the sand-making machine.

Reasons and Solutions for The shutdown of The Sand-making Machine

1. The material in the crushing cavity is blocked

The blockage of the material will cause the sudden stop of the equipment, which is a common phenomenon.

The reasons for the blockage of materials in the crushing chamber of the sand-making machine are as follows

(1) Feeding is too fast

When the sand-making machine is just started, if the material put in is too large or too hard, it will cause the equipment to block and also vibrate, so the equipment cannot be officially put into production when it is just started. At the same time, the speed of feeding materials is not easy to be too fast, otherwise, it will lead to the phenomenon of blockage.

(2) The size of the discharge opening

When the discharge port of the sand-making machine is too small and exceeds the minimum range of the equipment, some larger materials will accumulate at the discharge port of the crushing cavity, resulting in unsmooth discharge, and in severe cases, the crushing cavity will appear the phenomenon of blockage.

(3) The viscosity of the crushed material is too high

Due to the high water content or high viscosity in the crushed material, it will stick to the outlet of the crushing cavity when the sand-making machine is crushed, which will affect the discharge of the material and cause blockage. It is recommended that when crushing materials, screening work should be carried out first to avoid blockage during work.

(4) The hammerhead is worn or uneven

During the crushing work of the sand-making machine, when the hammer head is worn or uneven, the crushing force of the hammerhead will be reduced. When crushing hard materials, the crushing operation cannot be completed, so the material is broken unevenly or excessively. And reduce the service life of the hammer. At the same time, if the material is too large, the discharge of the discharge port will be affected, and in severe cases, the crushing cavity will be blocked.

Solutions

If the material in the crushing cavity is blocked, the material needs to be cleaned up. In the subsequent use, it is necessary to strictly control the feed particle size and the materials with more water content to enter the crushing cavity. It is forbidden for materials with large particle sizes or high water content to enter the machine, and the feeding should be kept uniform to avoid excessive feeding.

2. The V-belt is too loose

Check if the V-belt is too loose or loose.

Solutions

If it is too loose to cause downtime, it is necessary to adjust the tightness of the V-belt. If the V-belt loses its tightness due to long-term use, the V-belt needs to be replaced.

3. Voltage problem (inappropriate working voltage)

When the working voltage of the production site is too low, it is not enough to maintain the normal operation of the sand-making machine, which will cause the sand-making machine to stop.

Solutions

Adjust the equipment voltage, select the voltage that meets the equipment requirements, and restart.

4. Internal parts come off

If there is a metal collision sound before the equipment is shut down, it may be that there are parts in the crushing chamber that have fallen, causing the sand-making machine to stop suddenly.

Solutions

It is necessary to check the inside of the equipment to confirm that the internal parts are falling off, and then install them correctly.

5. Impeller stuck

When hard objects such as metal enter the crusher, the impeller of the sand-making machine may be stuck, causing the equipment to fail to work.

Solutions

It is necessary to strictly control the hardness of the material, and prohibit the entry of unbreakable objects.

6. The spindle is broken or the bearing is locked

Solutions

If it is caused by the fracture of the spindle, the worn spindle needs to be repaired or replaced.

If it is caused by the bearing lock, it is necessary to find out the cause of the lock, install the bearing correctly, ensure that the bearing has a certain working clearance, and do a good job of lubricating the bearing, otherwise the problem cannot be fundamentally solved.

7. There is a problem with the device connection line

If the connecting wire is broken or has poor contact, the sand-making machine will also suddenly stop, especially when there is no sound without warning, it is likely that there is a problem with the connecting wire.

Solutions

If the connecting wire of the equipment is broken or has poor contact, it needs to be adjusted or replaced in time.

Know the Reasons for sand making machine Stop is Helpful

During the use of the sand-making machine, there may be a shutdown problem. At this time, it is necessary to stop the machine to find the reason and then carry out the maintenance of the sand-making machine, which not only delays the time, affects the efficiency, but also increases the production cost. The above reasons and solutions for common downtime of sand-making machines help us to a large extent to solve the problem of sudden downtime of sand-making machines, saving time and improving production efficiency. If you have questions about equipment, you can contact us.