8 Principles Guide You to Design Sand Making Production Line

With the vigorous development of infrastructure, the demand for sand and gravel aggregates is also increasing, and the machinery and equipment of sand and gravel production lines are also developing rapidly. How to make a sand making production line more reliable, efficient and energy-saving? Sand and gravel production line is a whole production line process. A series of processes in the process of making sand and gravel from ore are controlled and completed by sand and gravel production line equipment, which shows the powerful functions.

For the machine-made sand production line, if the early design is unreasonable, it will directly affect the later production. What aspects should be considered in a standard machine-made sand production line?

Eight principles for Design Sand making Production line

1. Determine Reasonable Coarse-crushing Position

Combined with the quality of mineral resources of the company’s existing mines or newly purchased mines, the planned mining period must be considered in the long-term. It should also be considered to arrange the sand and gravel plant near the quarry to reduce the transportation distance of raw materials. When the quarry is far away from the main users, it is advisable to arrange the rough crushing in the quarry, and the intermediate material after rough crushing will be sent to the main factory through conveying equipment for further processing and manufacturing.

2. Site Selection

(1) The site must avoid the blasting danger zone, the safety distance should comply with the provisions of the relevant regulations, and the distance from the blasting point should exceed 200m.

(2) The plant site should be close to the existing transportation roads, water sources and power sources.

(3) The factory site should be far away from towns or residential areas. When it must be installed in towns or residential areas, it should be arranged on the leeward side of the dominant wind direction and maintain the necessary protective distance.

3. General Graphic Design

(1) Meet the relevant specifications or regulations on technology, transportation, fire prevention, construction, etc.

(2) On the premise of meeting the technological requirements, the general layout should be as compact as possible to save land, and at the same time, there should be room for equipment operation and maintenance.

(3) Make full use of the existing terrain to carry out vertical design to reduce the amount of earthwork, so that the crushed materials can flow or flow freely.

(4) The rough breaking position should be close to the incoming direction of the material yard, and the finished material yard should be close to the transportation road.

(5) Important workshops such as crushing, screening and sand making should be avoided in karst caves, landslides, debris flows and filling sections. If it is necessary to arrange in the above-mentioned lots, it should be fully technically demonstrated, and reliable treatment measures should be taken.

4. Electrical Automation

The electrical automation design of electrical automation production technology should adopt advanced, reliable, high-level automation DCS or PLC control system to achieve high efficiency, energy saving, stable production, optimized control and other purposes, and minimize the number of operating posts and reduce production costs.

5. Building Structure

Under the premise of meeting the production requirements, the civil engineering design should arrange the proaduction equipment in the open air as much as possible to save the cost of civil engineering to the greatest extent. The architectural design should strictly comply with the current national architectural design codes and standards, and pay attention to the ventilation, heat dissipation, sound insulation and shock absorption of the workshop. Take technical measures such as fire prevention, explosion-proof, waterproof and moisture-proof.

6. Water supply and drainage and HVAC

(1) The water used in the production line mainly considers several aspects such as water for spray dust removal, water for washing sand and gravel, water for domestic use, and water for fire fighting. The drainage system adopts a separate drainage system for rainwater and production and domestic wastewater.

(2) In the heating area stipulated by the state, the design shall consider centralized heating.

(3) The design capacity of the compressed air station shall not only consider the total gas consumption of each gas consumption point in the whole plant, but also take into account factors such as pipeline leakage and safety factor.

7. Mining conditions

In terms of mining, through the analysis of mining exploration data, according to the conditions of the ore body, the development and utilization plan of the mine is formulated, the mining resources are rationally utilized, the restoration of farmland to forests is considered, and adverse geological disasters are avoided, so as to achieve development and utilization, ecological protection, resource conservation and environmental protection friendly.

8. Production Processing Design

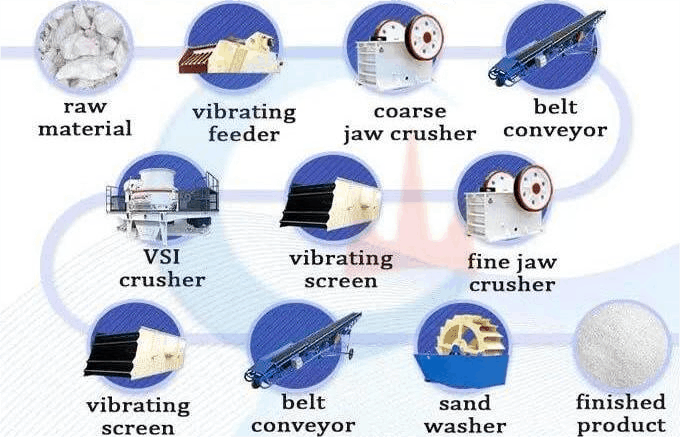

According to different production requirements, various types of equipment are combined to meet the different requirements of customers. The equipment of the machine-made sand production line mainly includes vibrating feeder, crusher, vibrating screen, sand making machine, sand washing machine, belt conveyor, etc.

The production line has a high degree of automation, low operating cost, high crushing rate, energy saving, large output, less pollution, and easy maintenance.

Eastman Technology Sand making Production Line

We can provide complete sets of machine-made sand production lines, quartz sand production lines, construction sand production lines, and sand making equipment, according to different process requirements, configure with appropriate types of equipment to give full play to its best performance. Through the comparison of the plans, reasonable selection of equipment for soil removal, crushing, screening, sand making, dust removal, and transportation. The process design balances the electricity, water and gas consumption of the whole plant, and uses the system theory to match the performance of each link of the machine-made sand and gravel production line, so that the entire production line runs with high quality and efficiency.