Sand Making Machine Common Problems & Solutions

Sand making machine is a very common machine for producing artificial sand. In the sand making process, we should not only choose a reasonable sand making machine, but also pay attention to the common faults and solutions that will occur during use. When the sand making machine is used for a long time, some common failures will inevitably occur. Therefore, when the sand making machine is abnormal during use, it should stop working immediately, and carry out common troubleshooting of the equipment to avoid unnecessary losses.

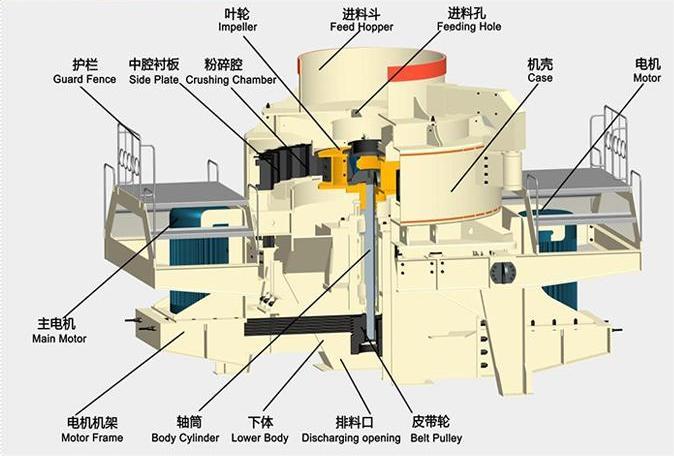

Sand making machine

The sand making machine is suitable for sand making of various materials, and can process river pebble, granite, quartz, basalt, limestone, dolomite, feldspar, gold ore, copper ore, manganese ore, lead-zinc ore, phosphate ore, steel slag , iron ore and other traditional materials. It can also process cheap “stone chips”, “melon stone”, etc., as well as solid wastes such as construction waste, coal gangue, and tailings.

In the field of mining, it can be used in building materials (asphalt, concrete mixing plants, etc.). Generally speaking, it is widely used in construction, mining, ores, roads, building materials, sand and gravel plants, refractory materials, concrete aggregates, construction waste, etc.

Sand Making Machine Common Problems And Solutions

1. Abnormal vibration of sand making machine

If the material fed into the sand making machine is too large to cause abnormal vibration, the feeding particle size of the stone can be checked. When the impeller of the sand making machine wears unevenly, it will cause abnormal vibration of the machine. At this time, the wear of the impeller and the alloy hammer head can be checked. If there is wear, it should be repaired and replaced immediately if necessary. The imbalance of the impeller of the sand-making machine causes abnormal vibration, and the balance of the sand-making machine needs to be adjusted. Abnormal vibration caused by improper foundation of sand making machine, check whether the anchor bolts are loose, and fix it immediately.

2. Large current deviation of two motors in the sand making machine

In the double-motors sand machine, the current of one motor is lower than the other is called inert reaction. The deviation should not be more than 10%. It is usually solved by adjusting and equalizing the tension of the transmission belt. Or checking the cleanliness of the terminal, the soft-start problem and other solutions.

3. The sand making machine produces a strong impact sound

Cause of failure: When the sand making machine is working, if foreign objects are mixed between the gears or the gears are loose and the teeth are loosened, the equipment will produce a strong impact sound, and this phenomenon will also occur when the rotating bearing or the link bolt on the foundation is loose.

Solution: At this time, it is necessary to stop the inspection, take out the foreign body and replace the worn gear, and tighten the connecting bolt.

4. The temperature of the upper and lower bearings of the sand making machine will be too high

When the instrument of the sand making machine shows that the bearing temperature exceeds the standard, it should be stopped for inspection. The reasons for the excessive temperature are as follows:

(1) The motor is overloaded for a long time;

(2) The main bearing is damaged. The operator should pay attention to the sound when the bearing is running. If the sound changes, especially when the sound is low and muffled, it indicates that the bearing has deteriorated;

(3) lack of bearing grease;

(4) The grease discharge groove is blocked, causing the pressure in the bearing housing to increase, resulting in the failure of the grease.

Solution:

1) Appropriately reduce the motor load.

2) Replace the damaged bearing.

3) Add grease.

4) Clear the grease drain groove.

5. The vibration value of the sand making machine is too large

The upper limit of the set value of the vibration switch of the sand making machine plays an extremely important role in protecting the equipment. When the vibration of the sand making machine reaches a certain limit, the power supply of the motor can be cut off through the vibration switch for protection. The reasons for the excessive vibration of the sand making machine are as follows:

1) The rotor has damage to the throwing head or the rotor has uneven wear;

2) Uneven material accumulation in the rotor;

3) The vibration damping pad is damaged;

4) The rotor or the tapered sleeve of the pulley is loose;

5) The main bearing is damaged;

6) The bolts are loose.

Solution:

1) Check the rotor wear and replace the corresponding throwing head;

2) Stop the machine to check the material accumulation in the rotor and adjust the feeding speed;

3) Replace the vibration damping pad;

4) Fasten the tapered sleeve of the pulley;

5) Replace the main bearing;

6) Tighten loose bolts.

How to maintain the sand making machine

1. When the sand making machine is running, the bearing can run better only when the lubrication is good. After the sand making machine is used for a period of time, lubricating oil should be added to ensure the normal operation of the machine. After working for a period of time, the bearing should be cleaned or replaced.

2. Shut down and rest regularly. In order to pursue production volume, some machines work day and night, which is definitely not good for the machine. We need to let the equipment work for a period of time, and then stop and rest. You can check and check the machine and so on. Make the sand making machine run more stably.

3. The tensioning force of the transmission triangle belt should be adjusted appropriately to ensure that the triangle belt should be selected in groups, so that the length of each group is as consistent as possible. It should be adjusted so that the current difference between the two motors does not exceed 15A.

External Factors affecting the sand making machine

The quality of the sand making machine produced by our company has passed the test, and the factors affecting the life of the sand making machine are mainly the factors affecting the life of the sand making machine. The customer does a good job of maintenance and maintenance, which can greatly extend the life of the sand making machine.

1. Environmental protection issues of crushing and sand making machines, “environmentally friendly crushing, environmentally friendly sand making.” Since the development of the green and environmentally friendly mine crushing policy concept, we can see batch after batch of small enterprises should be polluting at a speed visible to the naked eye. Problems were shut down for rectification or even shut down. During the operation of the crushing and sand making machine, the discharged wastewater will generally settle in the sedimentation tank, but it is time-consuming and laborious. So sometimes in order to catch up with the schedule, we can only pay people to deal with the wastewater, so in the face of these problems, all equipment manufacturers are carrying out research and development work in full swing. Strive to develop a crushing and sand making machine with a green environmental protection concept, and now the crushing and sand making machine with a green crushing concept on the market is obviously more favored.

2. Whether the equipment is durable or not, the bearings and components of the crushing sand making machine are always under pressure from the material, and they are in a state of wear all the time. Under this wear pressure, some equipment is prone to equipment failures question. For example, the parts of the equipment fall off or are seriously worn and need to be replaced. These situations all indicate the material and structural problems of the equipment itself. Therefore, the purchased crushing and sand making machine must meet the needs of the production line. At the same time, also To be stable and durable, not easy to strain.

3. After-sales problems of crushing and sand making machines, after-sales problems are a strong guarantee for buyers to avoid equipment failures, and as a result, no one can repair them. Therefore, the after-sales problem of the crushing sand making machine must exist. During the operation of the equipment, the probability of failure is increasing as time goes by, and failures represent downtime. However, on the production line, shutdown means loss, so it is an indispensable step to consider the follow-up after-sales problems of the equipment when choosing a crushing and sand making machine.

Our sand making machine

1. Low cost and low wear

The reasonable and simple structure of the sand making machine enables it to operate at a low cost in the production process. The crushing principle of “stone hitting stone” greatly reduces the wear of materials on wearing parts and reduces equipment operating costs.

2. Complete functions and good sand making effect

It has the functions of fine crushing and coarse grinding; it can feed the whole center, or it can fall and feed the center at the same time; it can make sand and shape the stone separately, and it can also make sand and shape at the same time, and the finished sand and gravel have good grain shape , Low needle flake content, suitable for aggregate shaping, artificial sand making and high-grade highway aggregate production

3. Wide range of materials

It can process more than 200 kinds of natural stones, including a variety of medium-hard and extra-hard materials; it can process stones with a moisture content of about 8%, and is less affected by the moisture content of the material

4. Energy saving and environmental protection, less dust pollution

The whole machine is sealed and reliable, and the noise during operation is lower than 75 decibels; appropriate environmental protection facilities can greatly reduce the amount of on-site dust; the product is cubic, with high bulk density, very little iron pollution, and more energy saving and environmental protection.

The sand making machine(VSI crusher) is a piece of high-performance crushed sand equipment with foreign technology. Our company sand maker perfect combination of the unique design of rotor structure, wear-resisting material process, crushing speed optimization and hydraulic design. Also a typic of professional fine grinding technology and machinery manufacturing which embody new technology and new process.

If you have more sand making machine FAQ and don’t know how to solve. Please contact tell us, we will give you a satisfactory reply. How much is the sand making machine? Get the VSI sand crusher price.