Phosphorite Ore Crushers Selection

Ore properties

In the selection of phosphate ore crushing and screening equipment, should be fully considered the hardness and particle size of the ore.

| Ore hardness | Ultimate Compressive Strength /Mpa | Platts Hardness /f |

| Hard | 160~200 | 16~20 |

| Medium | 80~160 | 8~16 |

| Soft | <80 | <8 |

crushing stage

For the phosphate ore processing plant,

1) Rough crushing: crushing 1500-350mm material to 350-100mm is coarse crushing,

2) Medium crushing: 350-100mm broken to 100-40mm,

3) Fine crushing: 100-40mm crushed to 30-10mm.

According to the particle size of the phosphate ore and the allowable feed size of the mill, the common screening and crushing processes are two-stage open-circuit process, two-stage closed-circuit process, three-stage open-circuit process, and three-stage closed-circuit process.

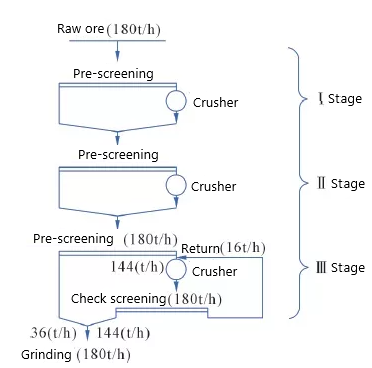

In this article, we require more than 80% of the phosphate rock with a particle size of less than 100 mesh after grinding treatment. To ensure the fineness of the grinding product, the particle size of the phosphate rock entering the mill is required to be less than 15mm. Therefore, a three-stage crushing process is adopted.

determine the crushing capacity

The mill feeding capacity of this project is 180t/h. According to the experience, check the return amount of screen material to ensure that it is not more than 10%, and the capacity of screening machines and crushers at all levels can be calculated.

| Equipment | Particle /mm | Capacity T/H |

| Raw ore | 0~200mm > 90% 200~400mm < 10% | 180 |

| Ⅰ stage screening | 0~400 | 180 |

| Ⅰ stage crushing | 200~400 | 144 |

| Ⅱ stage screening | 0~200 | 180 |

| Ⅱ stage crushing | 50~500 | 144 |

| Ⅲ stage screening | 0~50 | 180 |

| Ⅲ stage crushing | 15~50 | 160 |

| Check screening | 15~50mm < 10% | 160 |

| Enter grinding | ~15 | 180 |

select rock crushers

The selection of crushing equipment is mainly related to the nature of the processed phosphate rock material (hardness, density, viscosity, clay content, moisture, maximum particle size of the ore, etc.), processing capacity, crushed product particle size and equipment configuration and other factors.

Commonly used crushing equipment mainly includes jaw crushers, gyratory crushers, impact crushers, hammer crushers, cone crushers, and counter-roll crushers.

1) Coarse crusher

The coarse ore crusher generally uses a jaw crusher or a gyratory crusher, and an impact crusher can also be used when processing medium-hard phosphate ore. The processing capacity of the gyratory crusher is generally 2.5-3 times that of the jaw crusher, but the equipment is complex in structure, heavy in the body, high in equipment, and expensive. For 180tph processing capacity in this article, jaw crusher can be selected.

2) Medium crushing crusher

For medium crushing equipment for medium crushable phosphate rock, standard cone crushers, impact crushers, and hammer crushers can be selected.

The medium crushing capacity is 144t/h, the feed size is less than 200mm, and the output size is less than 30-80mm. The processing capacity of the roller crusher is too small, and the investment in the standard cone crusher is too high. Therefore, it is recommended to choose hammer crushers and impact crushers for medium crushing crushers.

3) Fine crusher

The crushing capacity is 160t/h, the feed size is less than 80mm, and the output size is less than 15mm. The processing capacity of the fine crushing jaw crusher is low, and the equipment investment of the short-head cone crusher is high. For the fine crushing machine, hammer crusher and impact crusher are recommended.

Due to the low hardness of the phosphate rock in this project, from the perspective of reducing equipment investment, jaw crushers should be selected for coarse crushing, and hammer crushers or impact crushers should be selected for medium crushing and fine crushing.

Get our product detail & price

Quick quotation, free crushing flow design, on-site service! Respond to you within 24 hours.