7 Differences Between Linear Screen and Circular Vibrating Screen

overview

Screening is an indispensable link in the sand and gravel aggregate production line. Screening is used to separate materials with different properties. The screening equipment uses rotation, vibration, reciprocation, shaking and other actions to divide the materials through the screen into several grades according to the size of the material to ensure that the sand and gravel materials meet the crushing requirements of the crushing equipment.

Screening machines are classified into circular vibrating screens, linear vibrating screens, roller screens, cylindrical screens, etc. according to their structure and movement characteristics. Different screens have their own advantages and scope of application. The more commonly used types of mine production are circular vibrating screen and linear vibrating screen. This article introduces the 7 differences between linear vibrating screen and circular vibrating screen.

product description

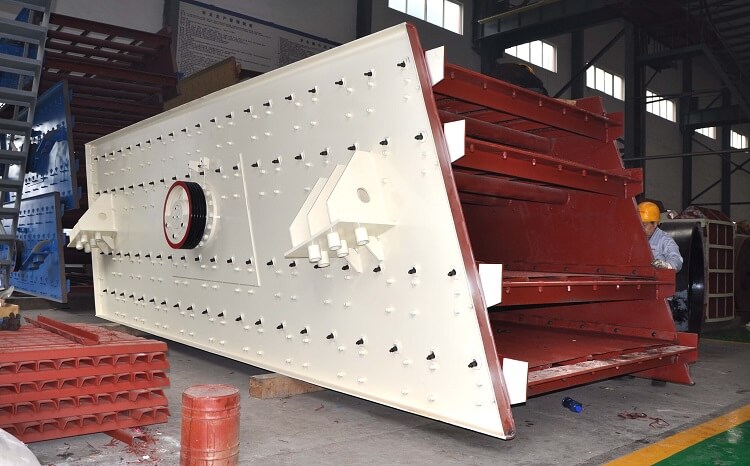

The circular vibrating screen uses the centrifugal force generated by the rotation of the eccentric mass in the vibrator to force the screen box, vibrator and other parts to make a forced continuous circular or approximate circular motion. The materials follow the screen box for continuous throwing motion on the inclined screen surface, layering when throwing, and particles passing through the screen when falling.

The circular vibrating screen has the characteristics of reliable structure, high screening efficiency, strong excitation force, sturdiness and durability, convenient maintenance, and safe use. It is widely used in mining, building materials, transportation, energy, chemical and other industries.

Linear vibrating screen

comparison

1. Movement track

The material on the linear screen moves forward in a straight line, and the material on the circular vibrating screen moves in a circular motion.

2. Vibration exciter

The linear vibrating screen exciter is composed of two shafts and works by the principle of vibration motor excitation, so it is also called a double shaft vibrating screen.

The circular vibrating screen is also called a single-shaft vibrating screen because the exciter is a shaft and uses an inertial motor to work.

3. Screen hole blocking

The material of the linear vibrating screen moves smoothly on the screen surface. If the feed is uneven or the material has a high humidity and viscosity, it is easy to block holes.

The material of the circular vibrating screen moves in a parabolic circular trajectory on the screen surface, so that the material is dispersed as much as possible, thereby improving the material’s bounce and reducing the phenomenon of hole blocking.

4. Installation angle

Generally speaking, the inclination angle of the screen surface of the linear vibrating screen is small, and the height of the screen is reduced, which is convenient for layout.

The circular vibrating screen usually has an installation inclination angle of 15-20 degrees, so as to change the moving speed of the material along the screen surface and improve the screening efficiency.

5. Material

The linear vibration screening materials are mainly light plates or stainless steel plates.

The circular vibration screening material is thick, and the box body is made of manganese steel, which can resist the impact of the material during the screening process.

6. Shape structure

The linear vibrating screen can adopt a fully enclosed structure without dust spillage, which is more conducive to environmental protection.

The vibration exciter of the circular vibrating screen is arranged above the center of gravity of the screen box, which is conducive to the rapid dispersion of materials, and the processing capacity per unit time is higher than that of the linear vibrating screen.

7. Applicable fields

Linear screens mainly screen fine particles, light specific gravity, and low-hardness materials, mainly dry powder, fine granular or micro-powder materials, and are generally used in food, chemical, building materials, and pharmaceutical industries.

The circular vibrating screen mainly screens materials with high specific gravity, large particles and high hardness. It is widely used in mining industries such as mines, coal, and quarries. In addition, some difficult-to-screen materials can also use circular vibrating screens.

other industry screen

rotary screen

hgih frequency vibrating screen