Heavy Hammer Crusher Models and Parameters

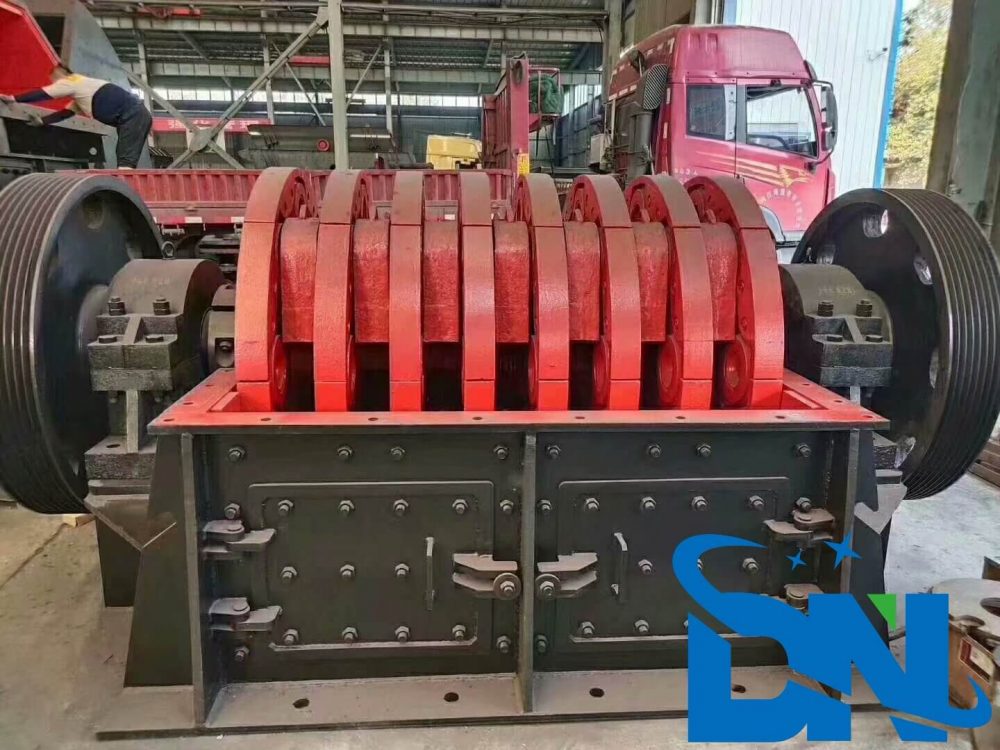

heavy duty hammer crusher

The heavy-duty hammer crusher is suitable for crushing various medium hardness and brittle materials. It can be used in dry and wet conditions, has the characteristics of large crushing ratio and high production efficiency. Eastman heavy-duty hammer crusher models are complete. Factory direct sales, preferential prices.

highlight & features

★1. Large feed size and high output

The maximum feed size can reach 1600mm, the crushing ratio is high, and the output can reach 3000 tons in a single machine. The design of the crushing cavity conforms to the principle of dynamics, and the unique structure design of no grate can increase the throughput of materials and can crush wet materials, which solves the problems of traditional hammers that are easy to block and low output.

★2. Fast crushing and forming, low investment and quick return on cost

For those with an hourly output of less than 600 tons, only 1 set heavy-duty hammer crusher can replace jaw crusher + impact crusher. For a 1500 tons-per-hour device, only 2 sets heavy hammer crushers are required, change multi-stage crushing to one-stage crushing.

Compared with the jaw crusher + impact crusher, the investment for the same output is reduced by about 35%.

★3. Good grain shape, low flake yield

The design of the crushing cavity conforms to the principle of dynamics. The material is crushed in three stages, and the finished product are shaped into a cube with reasonable gradation, which conforms to the national construction material standard. The unique self-flow groove design of the movable liner can automatically discharge qualified materials with a diameter smaller than the gap, which reduces the repeated crushing of materials in the crusher and greatly reduces the powder rate.

★4. Wear-resistant hammer head

Eastman focuses on the research and development and production of crusher hammers. So far, we has more than 20 years of experience in the casting and production of wear-resistant hammers, and can produce wear-resistant castings with a unit weight of less than 10 tons. The high-chromium alloy double-liquid composite hammer has won the “China’s Best Hammer Award” and has been hailed as the “most wear-resistant hammer hammer” in the industry.

★5. Reasonable structure

The back of the crusher adopts a ribbed structure, fixed by double nuts, and the rotor hammer head can rotate 360 degrees. The hammer head is heavy and the diameter of the rotor disk is large, which can resist the strong impact of large materials. The inner liner of the casing is tightly arranged and is fixed by 10.9 high-strength squares to ensure that the casing is firm and never deformed, and the discharge granularity is adjustable. After the optimized design of the lower casing, the traditional hammer breaker strips control the discharging particle size, reduce the wear of the hammer in the crushing cavity, and increase the life of the hammer by 3-5 times, which is more energy-saving and more efficient.

specification

heavy hammer crusher price

How much is a heavy hammer crusher? On the market, it ranges from around USD 10,000 to 150,000. The price difference is related to the type of equipment and model output. In addition, it also depends on the raw materials, sales mode, and overall quality of the equipment.

To get a quotation for the hammer crusher, please click on the online chat, a sales manager will serve you online and enjoy a 7-9.5% discount. Eastman has focused on the production of various mining equipment for more than 40 years. Welcome to visit the factory and provide general contracting services for “EPC” projects.

Get our product detail & price

Quick quotation, free crushing flow design, on-site service! Respond to you within 24 hours.