Custom Sand Making Plant Equipment And Solutions

Machine-made sand technology is becoming increasingly mature, and currently, machine-made sand is comparable to natural sand, which alleviates the scarcity of sand and gravel aggregates, and the profits are considerable. So, how to configure a complete sand-making plant? Let’s get to know the machine-made sand first.

What is the use of machine-made sand?

Machine-made sand, also known as artificial sand, has different specifications. It is configured into ultra-fine sand, machine-made sand concrete, mixed sand concrete, plastic concrete, high fluidity concrete, and pumped concrete according to different requirements. Machine-made sand and mixed sand have a relatively high demand. It applies to concrete with strength grades of C60 and below in construction projects such as architecture, municipal engineering, and transportation. When meeting corresponding technical requirements, the produced material is suitable for application in concrete projects such as ports and water conservancy. Those people familiar with the sand and gravel industry are familiar with it. Currently, the country is supporting the development of the machine-made sand industry, and the use of machine-made sand is becoming increasingly widespread.

Principles For complete sand-making Plant Design

- Get to know the nature and requirements of materials

Before configuring the sand production line, it is necessary to clarify the properties of the raw materials, such as hardness, size, etc. Based on the crushing materials, production requirements, and requirements for finished product particle size choose a stone crusher and sand-making machine. The selection of crushing and sand-making equipment should not only meet the production capacity but also consider the size of the feeding port to prevent materials from entering.

- Economic budget

The economic foundation determines the superstructure. When configuring sand production lines, it is necessary to choose different production line flow charts based on one’s budget. Don’t purchase with no purpose, the one that suits your working site is good. Users should configure it according to their actual purchasing ability.

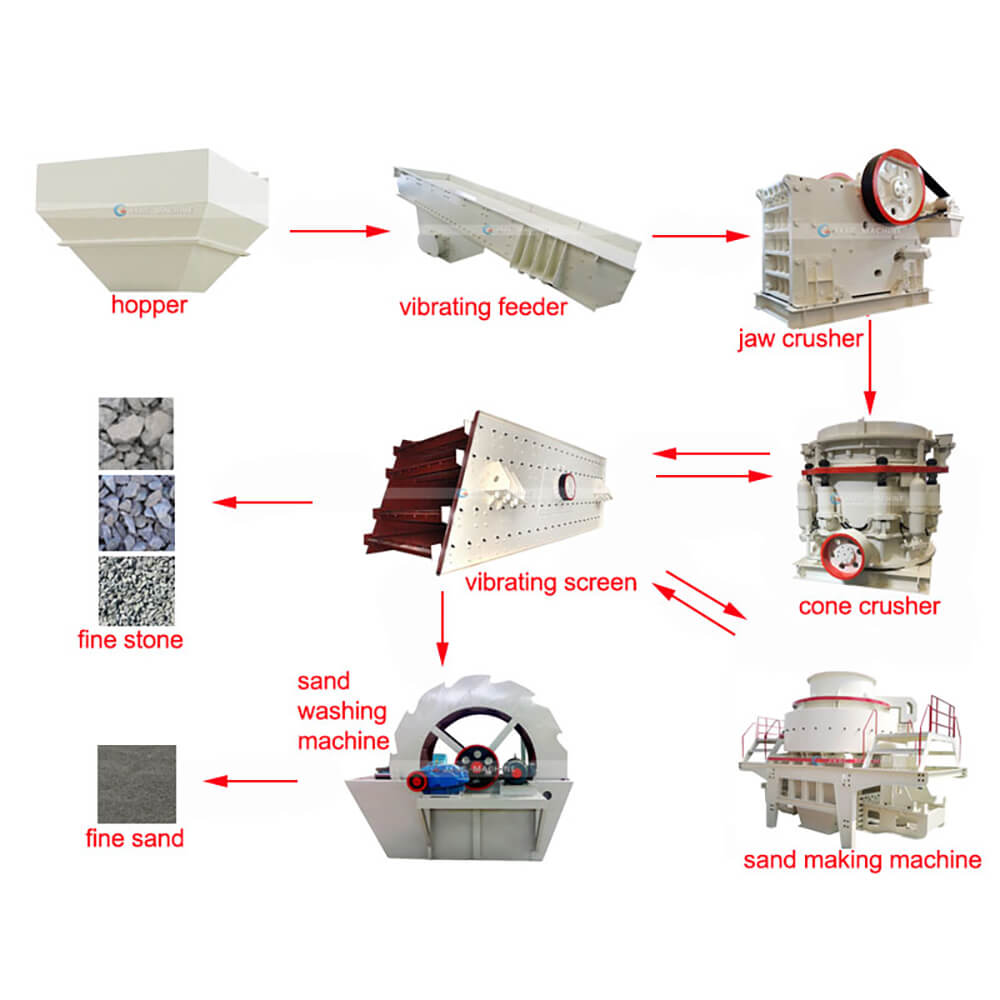

Introduction Of Sand-Making Plant Flow

Usually, the sand-making plant consists of three main steps: feeding, crushing, and screening, which are generally composed of vibrating feeders, jaw crushers, sand-making machines (vertical shaft impact crushers), cone crushers, impact crushers, vibrating screens, sand washing machines, belt conveyors, and centralized electrical control equipment.

- The stones are uniformly fed into the coarse jaw crusher by the vibrating feeder for preliminary crushing, and then the crushed materials go to the impact crusher for further crushing. Then the crushed material goes to a vibrating screen to separate different specification sand stones.

- Those stones that do not meet the particle size requirements return to the impact crusher for further crushing. The material is uniformly fed into the jaw crusher by a vibrating feeder through the material bin for coarse crushing.

- The crushed material goes to an impact crusher (cone crushers are also commonly used in production lines according to different needs) for further crushing.

- The fine crushed stone goes to a vibrating screen for screening to get several specifications of the stone. At this time, if there requires a sand-making process, an impact crusher will also be equipped for sand-making and shaping.

- The sandstones that meet the particle size requirements are transported to the finished material pile by the belt conveyor. The stones that do not meet the particle size requirements return to the impact crusher for further crushing, forming a closed circuit with multiple cycles.

- The particle size of finished products can be combined and graded according to user needs. We can add auxiliary dust removal equipment to the production line to protect the environment.

What Are The Equipment For Sand Making Plant?

We will introduce and analyze the equipment configured on the commonly used sand-making production line.

- Firstly, the jaw crusher has wide application in the rough crushing of materials. The jaw crusher is the most common crushing equipment among the coarse material crushing equipment nowadays. The reason it is so popular is because the jaw crusher performs well in the coarse crushing process. In addition, when processing the quarry to the raw stones, the jaw crusher demonstrates a “no refuse” momentum, which is undoubtedly beneficial for the sand production line.

- Next is the spring cone crusher, which is for fine crushing. The spring cone crusher is currently the most popular equipment among cone crushers. The spring cone crusher is named the “crushing equipment that combines the advantages of all cone crushers.” From this sentence, we can know that the performance and application of the spring cone crusher will not be inferior to other cone crushers.

- The impact crusher is the “soul” of sand production line equipment. Its existence improves the quality of aggregate and sand and also ensures the profitability of the sand production line. The impact crusher is aimed at the shortage of natural sand and stone, the limitation of river sand mining, and the low quality of machine-made sand, which is of great concern to the public. The impact crusher produces regular sand and stone particles during crushing. It fully meets the construction material requirements of sand and gravel and is not inferior to natural sand and gravel.

Stone sand-making machine

1. Professional sand making equipment – VSI sand making machine

VSI sand-making machine is a professional sand-making equipment with many advantages such as good sand-making effect, high output, and stable operation. It has a high market share and saves 50% of energy compared to traditional sand-making machines. It is also known as a vertical sand making machine, stone sand-making machine, etc. It can crush various rocks, sand and gravel, and river pebbles into construction sand with different particle sizes. The sand has uniform particle size and high compressive strength, which is more in line with the requirements of the infrastructure industry and improves the quality of construction sand.

2. Sand making equipment – roller sand making machine

Double roll sand-making machine, also known as double roll crusher, is mainly used for sand-making of mineral ores and rocks with medium hardness or below. It is also suitable for crushing raw coal (including coal gangue) in large coal mines or coal preparation plants and has the characteristics of reliable operation and low operating costs. The discharge particle size is adjustable, which adjusts spring pressure to control the finished material between 0-8mm. However, the output is relatively small, making it more suitable for small sand-making plants.

The roller sand-making machine mainly relies on a driving device consisting of two electric motors. It is transmitted to the groove wheel through a V-belt to drive the two roller wheels to rotate relative to each other to crush and crush the material.

Eastman is a professional mining equipment manufacturer with 38 years of rich experience in the mining construction industry. We can also provide lab equipment. Welcome to consult our professional team to get factory prices. According to your situation and product requirements, we will design a complete sand-crushing production line flow chart and provide an accurate quotation.