Clay minerals Sand Making Machine & Plant

Clay Minerals

Can clay minerals make sand?

Clay is widely distributed in rocks and soil, and it is mainly formed by silicate minerals after weathering. In order to give full play to the value of clay, after processing, it can be used as a resource in the fields of industry, cement, model manufacturing, and art models. Generally, water does not easily pass through clay, and it has good plasticity, so the clay can generally be used as a raw material for sand making.

What machine is used for making sand from clay minerals?

Sand-making machine is an important tool for processing clay. As the types of sand making machines are relatively complete, they are HVI sand making machine, shaping machine, VSI sand making machine, HX sand making machine, in terms of output, sand making effect and price, and at the same time for To protect the plasticity of clay, VSI sand making machine is recommended here.

The impact sand-making machine can crush raw materials less than 5 cm, with an output of about 20-500 tons per hour. It uses a high-speed rotating impeller for crushing. It has two working methods: stone beating and stone beating, which can achieve two functions of crushing and shaping. The impact-breaking sand-making machine adopts optimal wear-resistant materials, has a long service life, and the finished product is full of grain, reasonable gradation, and low powder content. Eastmancrushing’s VSI sand-making machine is a new type of sand-making equipment with a simple structure design and reasonable layout. It is developed with high-quality materials and mature technology. It has stable performance during work, a low failure rate, and high work efficiency.

Why use VSI sand-making machine to process clay minerals?

- In terms of effect: VSI sand-making machine has the crushing principles of “stone-on-rock” and “stone-on-iron”, and the sand-making effect is good.

- In terms of output: VSI sand making machine has a low output of 60 tons and a high output of 520 tons, and the equipment has a complete model to meet the different needs of customers.

- In terms of price: The structure design of the VSI sand-making machine is relatively simple, its hydraulic cover can be opened, and it has a separate oil station, which is convenient for customers to check and repair, and has low investment costs.

Not only that, the VSI sand making machine produced by Eastman crushing can process granite, stone powder, limestone, river pebbles, etc. in addition to clay, and as a direct-selling manufacturer, Eastman crushing offers customers a relatively cheap price.

How much is a VSI sand-making machine?

After understanding the types of equipment, everyone is more concerned about the price point. In comprehensive market conditions, the price of clay sand-making machines ranges from tens of thousands to hundreds of thousands. The large range of price changes is inseparable from factors such as production capacity, manufacturer, model, and type.

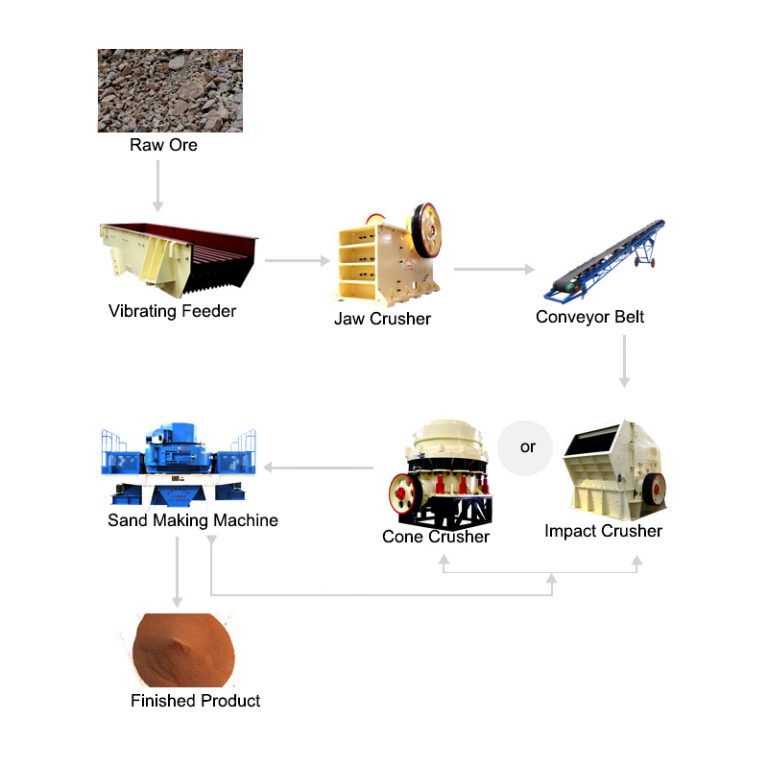

Clay Minerals Sand Making Equipment

Under normal circumstances, a complete clay sand production line mainly includes equipment including a vibrating feeder, jaw crusher, cone crusher (impact crusher), clay sand making machine, circular vibrating screen, sand washing machine (optional ), belt conveyor, and so on.

Clay Minerals Sand Plant

In the working process of the clay sand production line, large pieces of clay materials are evenly sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing, and the coarsely crushed clay is sent to the cone crusher (or counterattack) by the belt conveyor. Crusher) for medium crushing. The crushed clay is sent to the clay sand making machine by a belt conveyor to make sand, which is sieved by a circular vibrating screen, and the finished sand (under the sieve) is sent to the After being cleaned by the sand washing machine, it is sent to the finished product pile through the belt conveyor; the large particles (overseen) are sent from the belt conveyor to the clay sand making machine for fine crushing, and the finely crushed stone is sent to the vibrating screen again by the belt conveyor Screening is carried out to form a closed circuit for multiple cycles. Until the clay part is made into sand, the sand making process of the clay is finished.

What is the configuration of the clay sand production line with an hourly output of 50 tons?

Take 50 tons per hour, the finished product size is 0-5mm, 5-15mm as an example, the specific configuration is a raw material warehouse, GF0942 vibrating feeder, PE600*900 jaw crusher, VSI6X8018 sand making machine, vibrating screen, conveyor belt.