3 Cases of Sand Making & Washing Plant

Whether it is natural sand or machine-made sand, the price has soared all the way. For the water washing sand factory, the profit is very considerable, and the cost recovery of users is not a problem in the short term. However, whether the environmental protection is up to the standard is the key condition to determine whether it can be based on the market. How to invest in an environmental protection water washing sand factory?

What equipment is needed to invest in an environmentally friendly sand washing plant?

What equipment needs to be configured for a water sand washing production line? Due to different customer processing standards, the types and models of sand washing equipment may be different. Generally speaking, feeding, screening, sand washing and transportation are the core equipment. The following introduces the common design schemes for your reference.

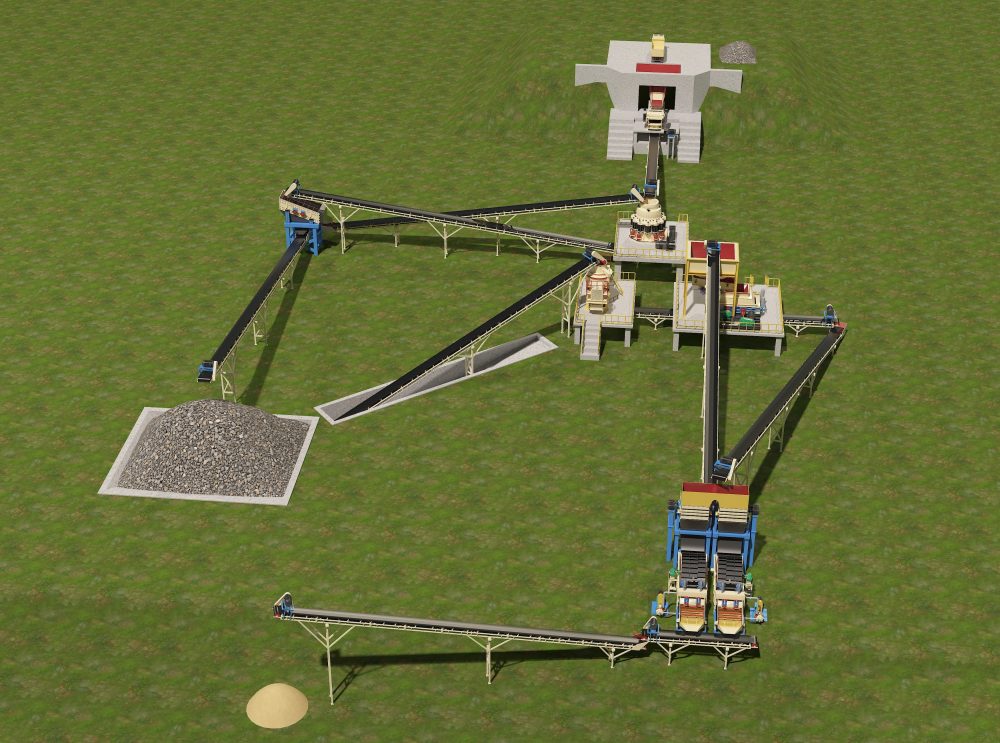

Flow Chart 1: 200TPH Sand-making Washing Plant

Material: Granite,hard stones, ect

Capacity: 200tph

Input Size: Under 600mm

Output Size: 0-5mm,5-10mm

The granite material first transports by truck to Hopper, and then the granite material fell into a vibrating feeder( DN590*110 )because of the height difference.

A vibrating feeder transports the granite material to the jaw crusher(PE-750*1060) for the first crushing.

After first crushing the output from the jaw crusher is transferred by belt conveyor to secondary crushing machine compound cone crusher(DN1400) to get a smaller size.

Then the smaller size goes the 2 layers vibrating screen(2YD2160) to get 3 product, screen mesh size 35mm and 5mm, the first size is size over 35mm go back to cone crusher for crushing to small size, the second middle size 5-35mm transport to transit hopper by belt conveyor to sand making machine(DN9000)to get fine material and transport to second vibrating screen(2YD2470), and third size 0-5mm material transport to second vibrating screen(2YD2470).

When the material gets to the second vibrating screen(2YD2470).mesh size is 10mm and 5mm, the size over 10mm go back to transit hopper to sand making machine(DN9000), the 5-10mm material go the first output product, the size second output 0-5mm go to the sand washing machine to get a clean product. And finally get output size 0-5mm,5-10mm.

The flow chart can also be revised by the client’s requirement.

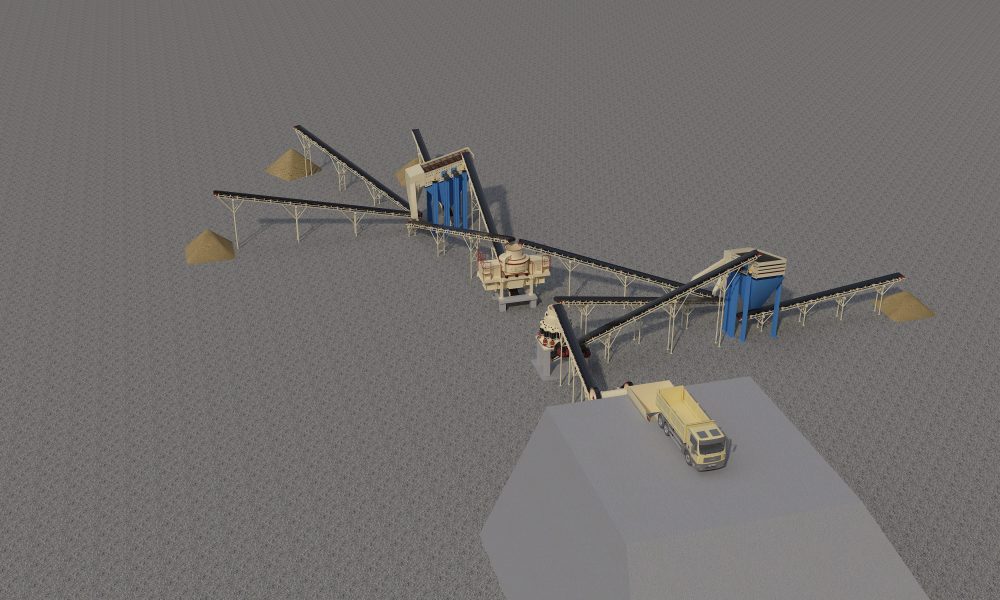

Flow Chart 2: 350-400TPH Complete Sand Making And Washing Plant

This setup is a 350-400tph complete sand making and washing plant, the raw material is granite, the input size is 0-780mm, output sizes are 0-5mm. It is configured with hopper, vibrating feeder DN6013, primary jaw crusher PE-900*1200, cone crusher DN1650, vibrating screen 2YD2470, VSI DN10000, 2-layer vibrating screen 2YD2470, and belt conveyors.

- The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper;

- The vibrating feeder feeds the stones evenly to the primary jaw crusher;

- The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher by a belt conveyor;

- The crushed output materials from the secondary cone crusher will be transported to the two-layer vibrating screen;

- After screening by the two-layer vibrating screen, will get 0-35mm and +35mm materials. 0-35mm materials will be transported out by a belt conveyor to stockpile, +35 materials will be transported back to the cone crusher for re-crushing.

- 0-35mm materials in the stockpile will be fed to the conveyor belt by a vibrating feeder. Then it will be transported to the VSI crusher to be crushed and shaped. the output materials will be transported to the second and third vibrating screen;

- After the screening, will get 0-5mm materials, the +5 mm materials will be transported back to double roller crushers. The advantage of double roller crushers is less dust and a relatively high sand output rate.

- 0-5mm material will be washed by two sets of wheel sand washers, it can be a spiral type sand washer.

- The output of the sand washer will be dewatered by the fine sand recycling machine DN2045.

The role of the VSI crusher in this setup for producing high standard output materials for mixing stations, asphalt stations, etc.

This crushing plant is suitable for processing many kinds of hard stones, like basalt, pebbles, granite, diabase, etc.

The capacity for this crushing plant can be customized as per request such as 200tph, 300-400tph,1000tph, etc.

Flow Chart 3: 200TPH Aggregate Making Plant in Ghana

This setup is a 200tph Aggregate making plant in Ghana, the raw material is granite, the input size is 0-630mm, output sizes are 0-5mm, 5-15mm, 15-31.5mm.

It is configured with hopper, vibrating feeder DN4911, primary jaw crusher PE-750*1060, cone crusher DN1400, vibrating screen 2YD2160, VSI DN9000, 3-layer vibrating screen 3YD2160, and belt conveyors.

- The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper;

- The vibrating feeder feeds the stones evenly to the primary jaw crusher;

- The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher by a belt conveyor;

- The crushed output materials from the secondary cone crusher will be transported to the two-layer vibrating screen;

- After screening by the two-layer vibrating screen, will get 0-5mm, 5-35mm, +35mm materials, 0-5mm materials will be transported out by a belt conveyor to stockpile, 5-35mm materials will be transported to VSI Crusher, +35 materials will be transported back to cone crusher for re-crushing.

- 5-35mm materials will be crushed and shaped by a VSI Crusher, the output materials will be transported to the second vibrating screen;

- After the screening, will get 0-5mm, 5-15mm, 15-31.5mm materials, the +31.5mm materials will be transported back to the VSI crusher.

The role of the VSI crusher in this setup for producing high standard output materials for mixing stations, asphalt stations, etc.

This crushing plant is suitable for processing many kinds of hard stones, like basalt, pebbles, granite, diabase, etc.

The capacity for this crushing plant can be customized as per request such as 50tph, 100tph, 200tph, etc

The above configuration scheme is not fixed. The specific configuration depends on the specific situation of each user. If you want to quickly understand the production scheme suitable for you, you are welcome to click online consultation to obtain the production scheme suitable for you. According to various needs, a professional technical team will conduct a comprehensive analysis and tailor-made design.