Process Of Construction Waste Sand Making Plant

As the construction industry expands, so does the demand for cement, a key material in building infrastructure. However, the production and use of cement generate significant amounts of waste, which, if not properly managed, can pose serious environmental challenges. Recycling cement waste into sand has emerged as a viable solution to minimize waste and promote sustainable construction practices. This article will explore the sources of cement waste, the processes for transforming it into sand(construction waste sand making plant), and its applications in the construction industry.

Sources of Cement Waste

Cement waste primarily arises from several key sources:

- Manufacturing Waste: During cement production, crush, transport, and store the raw materials with dust and fine particles. These by-products, often considered waste, can accumulate and require management.

- Construction and Demolition: The demolition of old buildings generates large quantities of concrete, bricks, and other cement-based materials. If these materials are not reused or recycled, they often end up in landfills, contributing to environmental degradation.

- Excess Material from Construction Sites: In various construction projects, produces surplus cement and concrete. If not processed, this excess can lead to significant waste.

- Industrial By-products: Some cement production processes yield by-products like fly ash or slag, which are recycled into sand with appropriate processing.

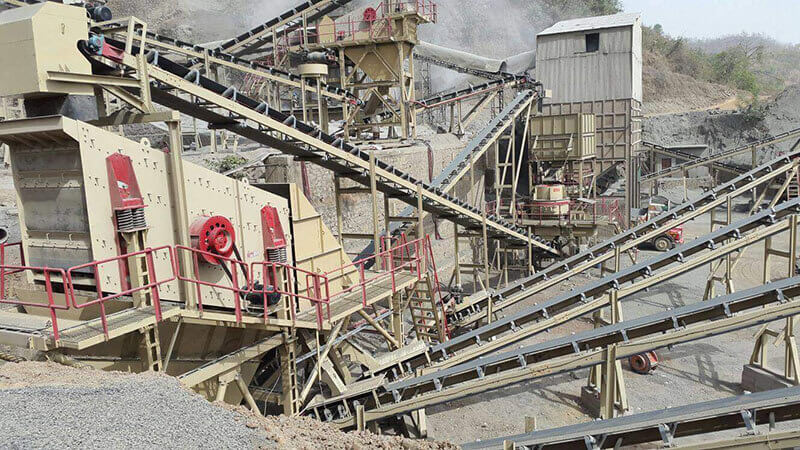

Construction Waste Sand Making Plant Process

It must undergo a series of processing steps to utilize cement waste. The following outlines the typical methods involved in transforming cement waste into sand:

Collection and Transportation

The first step involves collecting cement waste from construction sites or production facilities. Transport the waste to recycling facilities by specialized vehicles designed to prevent contamination and ensure safe handling.

Crushing

Upon arrival at the recycling facility, the cement waste undergoes mechanical crushing. Stone crushers break down large pieces of concrete and other materials into smaller fragments. This process reduces the volume of waste and prepares it for further processing. The choice of crushing equipment depends on the nature of the waste and the desired final particle size.

Screening

After crushing, the material enters the vibrating screen to separate fine particles from larger gravestones. Screening helps remove oversized materials and impurities, ensuring that only suitable particles proceed to the next stage. This step is crucial for maintaining the quality of the final sand product.

Grinding

Grinding may be necessary to achieve the desired sand consistency for the larger particles. Grinding equipment, such as ball mills pulverize the material into finer grains. Proper control of this process is essential to avoid over-grinding, which can negatively affect the properties of the sand.

Washing

Depending on the initial composition of the cement waste, washing may be required to remove contaminants such as dust, oil, or other residues. This step ensures the final product is clean and used in construction applications.

Drying

After washing, the material is subjected to drying to reduce moisture content. It is vital to ensure that the sand remains stable when mixed with other materials for concrete or mortar. Drying through the hot air drying systems or rotary dryers.

Storage

Finally, the processed sand is stored in appropriate conditions to prevent recontamination. Proper labeling and separation from other materials are essential for maintaining the quality of the recycled sand until it is ready for use.

Applications of Recycled Cement Sand

Recycled sand produced from cement waste is widely used in various industries, including:

- Construction Materials: The most common use of recycled sand is in concrete and mortar production. It can replace a portion of natural sand, reducing the demand for virgin materials and lowering construction costs.

- Road Construction: Recycled sand is suitable for use in road-based materials and subgrade layers, enhancing the stability and durability of roadways.

- Landscaping and Soil Improvement: In landscaping projects, recycled sand can be used for soil amendment and as a component in planting beds, promoting healthy plant growth.

- Environmental Benefits: Utilizing recycled sand contributes to sustainability by reducing landfill waste, conserving natural resources, and lowering the carbon footprint associated with material extraction and transportation.

Environmental Impact and Sustainability

The recycling of cement waste into sand offers significant environmental benefits.

- By diverting waste from landfills, it minimizes the ecological footprint of construction activities.

- Additionally, using recycled materials reduces the need for natural resource extraction, which can lead to habitat destruction and other environmental issues.

- Furthermore, implementing efficient recycling processes helps to lower greenhouse gas emissions associated with cement production and transportation. This practice aligns with global sustainability goals and promotes a circular economy within the construction industry.

Challenges and Considerations

While the process of recycling cement waste into sand presents numerous benefits, there are also challenges to consider:

- Quality Control: Ensuring the quality of recycled sand is essential for its acceptance in construction applications. Variability in the composition of cement waste can lead to inconsistencies in the final product.

- Market Acceptance: The construction industry must recognize the value of recycled materials. Increased awareness and education about the benefits of using recycled sand can help drive its adoption.

- Regulatory Frameworks: Develop clear regulations and standards for the recycled materials and facilitate their integration into mainstream practices.

- Economic Viability: The economic feasibility of recycling cement waste into sand depends on various factors, including processing costs, market demand, and the availability of alternative materials.

Conclusion

Processing cement waste into sand presents a promising opportunity for the construction industry to address waste management challenges while promoting sustainability. By adopting effective recycling methods, the industry can reduce its environmental impact, lower costs, and contribute to a more sustainable future. As awareness of environmental issues continues to grow, the importance of recycling cement waste will likely become more pronounced, paving the way for innovative practices and technologies to enhance resource efficiency in construction further.

Eastman is a professional mining equipment manufacturer with 38 years of rich experience in the mining construction industry. We can also provide lab equipment. Welcome to consult our professional team to get factory prices. According to your situation and product requirements, we will design a complete sand-crushing production line flow chart and provide an accurate quotation.