Have you ever meet the situation that recovered artifical sand contains a large amount of mud, and the loss rate of fine sand is increasing serious?

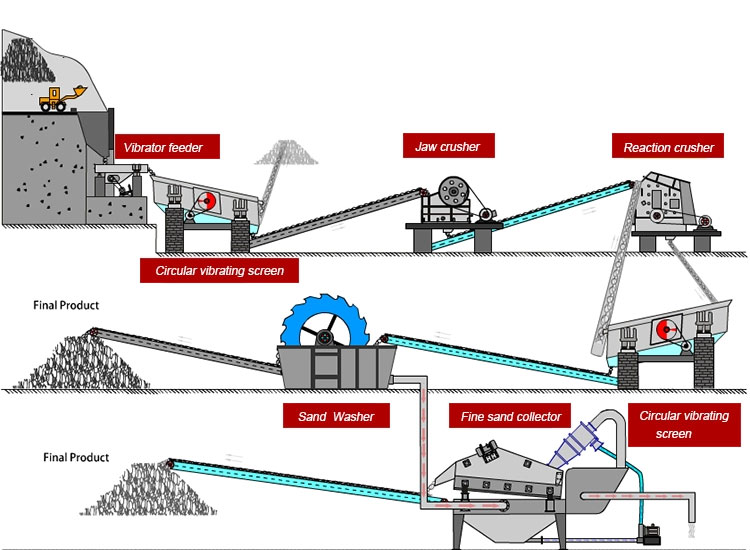

In the later stage of the sand production line, for sand with high mud content or sand-water mixtures with high sand content, only the sand washing machine may not meet the requirements of the final finished sand, and there is also a serious drawback of the loss of fine sand. To solve this problem, a fine sand recovery system must be used. This article introduces 4 methods for your reference.

Solution 1. Using a fine sand recycling machine

As the name implies, the fine sand recovery machine is a commonly used fine sand recovery equipment. It needs to be used in conjunction with the sand washing machine to recover a large amount of fine sand lost by the sand washing machine in the traditional sand making industry (the loss can reach more than 20% when the loss is serious) to improve economic benefits At the same time, it reduces the disposal cost of tailings and the pollution and damage to the environment caused by the loss of fine sand.

When the fine sand recovery machine is used in a sand and gravel plant, the main function is sand washing and sediment separation, so it is also called a fine sand dewatering machine, a sediment separator, and a sediment extraction machine; when used in a concentrator, the main function is tailings recovery. So it is also called tailings recovery machine.

Solution 2. Using fine sand recovery machine with a dewatering machine

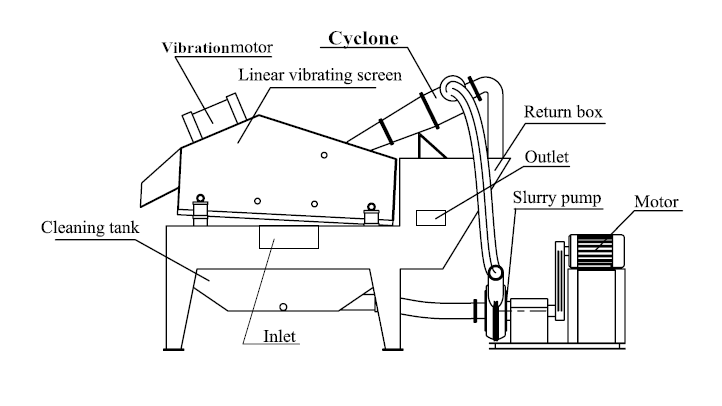

The dewatering fine sand recycling machine is divided into two systems, dewatering and recycling. The dewatering part includes a dewatering screen and a vibration motor, and the recycling part includes a vacuum high-pressure pump, a motor, a high-pressure separator, a return tank, and a cleaning tank.

Generally installed directly at the back of the sand washer, the sand washed by the sand washer can be cleaned twice, and the waste water discharged by the sand washer can also be separated from the sand, which fully solves the shortcomings of the sand washer (such as: finished product) Large water content, large mud content, large dust, difficult to remove impurities, etc.), greatly improving the quality of the finished product.

Solution 3. Sand washing and recycling machine

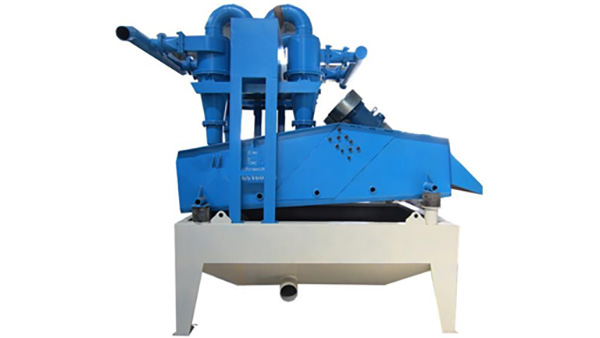

The structure of the sand washing and recycling integrated machine is composed of high-pressure separator, dewatering screen, impeller separator, reducer, vacuum high-pressure pump, cleaning tank, high-position return tank, motor, vibration motor and other components. The main function is to wash sand and recover fine sand at the same time.

The working principle is:

The sand-water mixture enters the cleaning tank, is separated by the impeller separator, and then enters the lower dewatering screen for dehydration treatment. The waste water (containing a large amount of fine sand, mud, dust and other impurities) overflowing from the cleaning tank is transported to the high-pressure separator by the vacuum high-pressure pump, and then the fine sand after centrifugation and classification is discharged into the upper layer of the dewatering screen through the sand nozzle. Waste water, mud, dust, impurities, etc. in the cleaning tank are discharged into the high-level return water tank through the overflow port of the high-pressure separator. The upper layer is finished with coarse sand, the lower layer is finished with fine sand, or coarse and fine sand are mixed.

Solution 4. Sand washing and dewatering machine

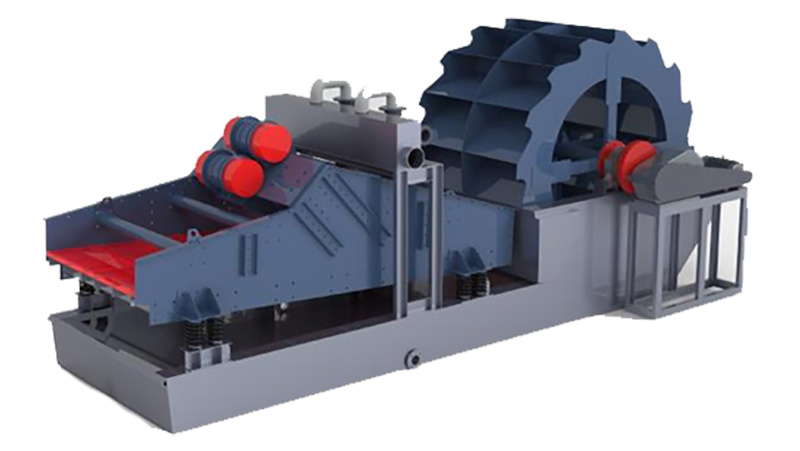

The sand washing and dewatering integrated machine combines the characteristics of sand washing machine and dewatering screen. The main function is to wash the sand with water, and further desilting, dewatering and secondary cleaning.

working principle:

The sand-water mixture enters the cleaning tank of the sand washer, is filtered and sieved by the bucket screen, and falls into the dewatering screen for dehydration treatment to remove a large amount of water in the sand. As shown below:

Conclusion

Although the above types belong to the fine sand recovery system series, different types of systems have different functions. For example, the dehydration type fine sand recovery machine has both dewatering and fine sand recovery functions, and the sand washing and recovery integrated machine has both water washing sand. And fine sand recovery function. Users can choose the most suitable equipment according to their own production needs when purchasing to ensure the best economic benefits.