Sand plant Information

Capacity: 500TPH

Output size: 0-5mm, 5-10mm, 10-20mm,

Input Size: <450mm

Location: India

Equipment Configuration: Vibrating Feeder, Jaw Crusher, Belt Conveyor, Cone Crusher, Vibrating Screen, Sand Making Machine.

Technological Process

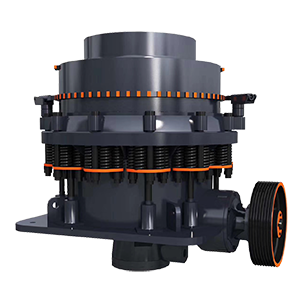

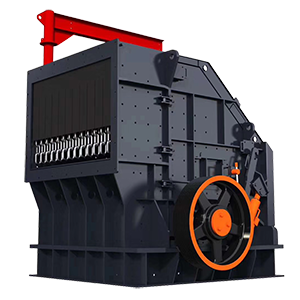

The whole aggregate production plant is divided into two parts, one is the crushing plant, the other is the sand plant. After the raw stone materials that containing mud are passed through the vibrating feeder. The mud is sieved out, and the stone raw materials fed into jaw crusher at a constant speed for crushing. Then fed to cone crusher for fine crushing.

After being crush by cone crusher, a part of the finished crushed stone product can be obtained. The aggregate of 5-40mm is transported to the sand-making machine and processed into 3 sizes of final products. The vibrating screen sifts out the crushed stone materials of these three specifications. The complete sand-making process is thus completed.

Our Advantages

The design of Eastman 500tph sand making plant is tightly and compactly. Each crushing equipment has been accurately calculated and configured into a complete production line. Therefore, the production efficiency is high, the output is large. Quality of finished product sand is good, grain shape is even.

➤Equipment Matches Well

In the whole sand and gravel production line of the process, each crushing, screening, making sand, transportation link, space cross layout strict. Besides, it covers a small area and has high economic benefit. High quality equipment and low output of stone powder. At the same time equipped with advanced electronic control operating system, which can ensure the production line discharge fast. Reliable and convenient operation, energy saving and high efficiency.

➤High Level of Automation

The complete sand plant except equipment start-up, suspension and routine maintenance, almost no manual operation. The sand plant has the advantages of simple process, high production efficiency, large output and low operation cost. The finished sand and stone have uniform particle size and good particle shape, which fully meet the building sand standards and high-speed material requirements.

➤Flexible Adjustment of Particle Size

The plant solves the problem that the quality of sand and stone particles produced by traditional processing equipment is not up to standard. And overcomes the traditional processing equipment because the rock is hard, the abrasion is serious and causes the production cost high shortcoming. The product line can adjust the particle size of the finished sand flexibly according to the different requirements of the particle size of the finished sand to ensure the timely production of the required product particle size and reduce the project investment.