Quarrying plant Information

Capacity: 200TPH

Output size: 0-3mm, 3-8mm, 8-15mm, 15-20mm

Input Size: 300-500mm

Application: Hydraulic Engineering, highways, metallurgy, construction.

Artificial sand making processing

1. The 300-500mm moorstone via vibrating feeder uniformly into jaw crusher for primaty crushing.

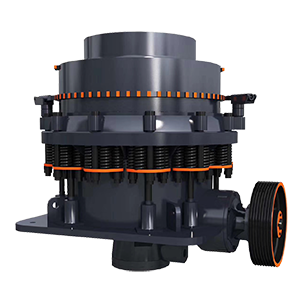

2. Crushed moorstone by jaw crusher fed into cone crusher for secondary crushing. There are produced five kinds of size, >40mm, 20-40mm, 15-20mm, 8-15mm, and <8mm. Therefore, we used 4 layer aggregate vibrating screen.

3. 15-20mm, 8-15mm, <8mm aggregates are need finished pruduct. bigger than 40mm crushed moorstones are transported cone crusher for crush again by belt conveyor. 20-40mm materials are transported sand making machine for fine crusher.

4. The vibrating screen is the last step to screening crushed materials of 3-8mm, 0-3mm, >8mm. More than 8mm metarials need convey to sand making machine for crush again. View The Flowchart

Equipment: hopper, vibrating feeder, jaw crusher, belt conveyor, cone crusher, vibrating screen, sand making machine.

Our Advantages

➤Professional Engineers Team

Tell us raw material of your aggregate plant, input size, output size, and capacity. Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you. Also, our engineers can design the flowchart according to your needs. Answer any aggregate questions for you.

➤Excellent Crusher Manufacturers

Our company was founded in 1985. In the aggregate crushing industries, we have 35+ years of machinery production of experience. All the equipment of stationary crusher plant, mobile(portable) crusher plant are choose the best materials, and meticulously casting every part. High Performance & Ease of Operation, many crushers equipment in stock.

➤Good Service

We have a office in Tanzania.The customers of regions near Tanzania and Tanzania, we provide installation service for free. All of our equipment, 1 Year Warranty.