The modern industrial use of aggregates began in the early 19th century, and the aggregate can be defined as particles of rock that, when combined in either a bound or an unbound condition, form a part of an engineering or building structure. Nowadays, aggregate varies in size and appearance and is an important part of the man-made environment. It also represents a significant proportion of the materials used in the construction industry.

So in order to meet certain product requirements for aggregate that is required for asphalt or concrete production, several important production processes must be controllable. And the crushing process in mineral and aggregate since come from this.

What is the crushing process?

Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses. Also, crushin processing is widely used in waste and recycling, mining, food processing, construction, and coal.

Industrial crushers are primarily used to take very large pieces of material and make them smaller. Having smaller pieces of the material allows for easier transportation, further processing, and/or better ability to differentiate the different compositions of the material.

Why crushing?

There are many practical purposes for industrial crushing. Waste products get crushed so they for easier disposal and/or recycling. You could crush wet materials, like cement, for use in construction and road building. Crushing is also very useful in the chemical industry for breaking down hard materials such as limestone or coal.

Many items and materials have a surprising amount of flexible space that can be eliminated in a crusher. If there is a very large piece of material, it may need to be crushed for easier storage, packaging and/or transportation. Or maybe there is an oversized piece of material that needs to be milled. It may need to be crushed in an industrial crusher before it can fit into other pieces of machinery. For example, a processing line at a mine may crush rock ore into smaller pieces before processing them further in a mill or grinder.

What is the crushing stage?

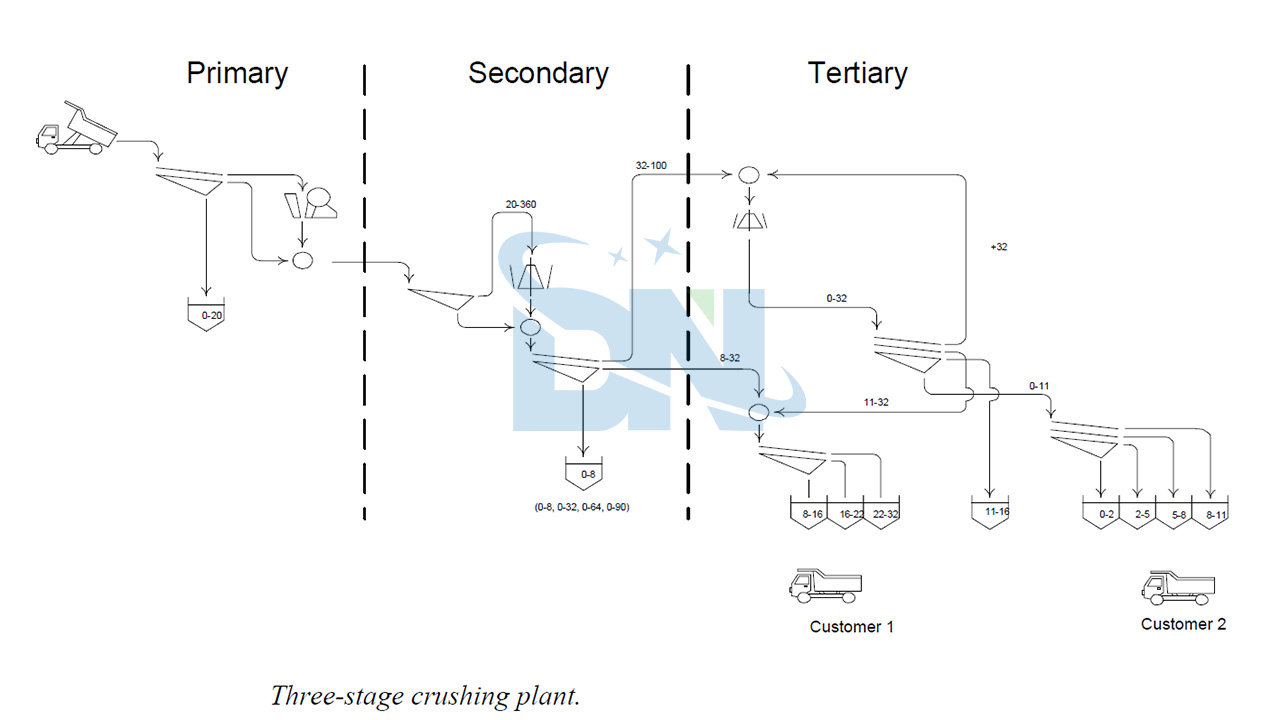

The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen into a 0-20 mm fraction and typically a 20-150 mm fraction. The 0-20 mm fraction contains soil etc. and is generally considered to be of poor quality. This fraction is often used in road construction applications that feature low quality requirements. The 20-150 mm fraction is transported to the secondary crusher on conveyor belts. The product from the secondary crusher is classified into macadam fractions such as 8-16 mm, 16-32 mm and 32-63 mm, which are used in road, railway and building construction because of their good draining capabilities. The products can be extracted immediately after the gyratory crusher as 0-32 mm or 0-63 mm fractions, if necessary; these materials are used when stability is needed for the given construction application. The tertiary stage produces fractions in sizes ranging from 0-2 mm to 16-32 mm. These products are used in asphalt and concrete.

What equipment are used in crushing process?

In the pre-industrial era, crushers were usually hand-held stones. The weight of the stone would help give the user more power. Querns and mortars are examples of the earliest crushers.

Nowadays, machinery used for crushing usually hold materials between two solid surfaces that are parallel to each other. Have you ever watched a movie scene where two walls are closing in on each other? It’s just like that. The solid surfaces close in together and sufficient force is applied so that the molecules of the material’s fracture and deform into the desired shape. It’s important that molecular composition of the machinery is stronger than the materials it is crushing to avoid damaged equipment or cross-contamination.

There’s a wide range of equipment that can be used for crushing materials. Different crushers are used depending on the type of material you’re trying to crush. Some crushing equipment is better for materials with a soft or medium density, and others might be more suited for the oversized material.

Types of machinery used for industrial crushing include:

- Jaw Crusher

- Gyratory Crusher

- Cone Crusher

- Impact Crusher

- Composite Crusher