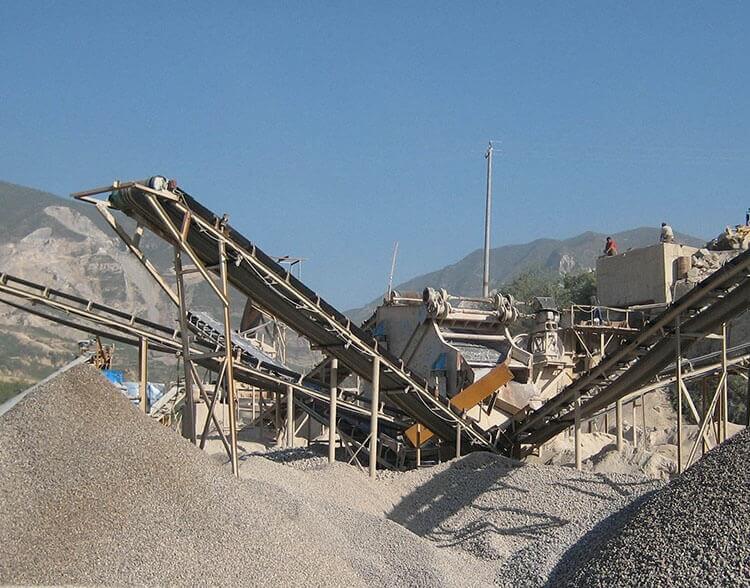

We know that Robo sand or manufactured sand is composed of grading particles of different sizes. During the production process, it falls from a high place to the stacking point. Under the action of gravity, the phenomenon of segregation will inevitably occur, so that the use of machine-made sand will cause certain.

So how to solve it? This blog will help you with our introduced 4 methods.

What is The Isolation Phenomenon?

Before learning the solutions, it is necessary for us to briefly understand what is the phenomenon of segregation:

During the mixing process, due to the difference in packing density between the large-diameter material and the small-diameter material, the magnitude and direction of the force are different when the external force is applied. The friction between the particles is not enough to resist the separation of the external force. It can’t be mixed uniformly, but gathered separately, this phenomenon is segregation.

How to solve it?

-

Solution 1: Humidified materials

A water spray nozzle is added on the conveyor belt of the outlet of the sand making machine. This measure can effectively reduce the generation of dust on the one hand, and on the other hand, the wet sand increases the cohesion between the particles, which can also effectively reduce the occurrence of segregation. This is why dry sand production is more prone to segregation than wet sand production.

-

Solution 2: Use a roller mixer

It is the initial method to spray water and dust on the finished product of machine sand, but the amount of water spray is not easy to control. The excessively large amounts of water will cause the machine sand to be too high and affect the use; too small to achieve the effect of reducing segregation and dust suppression. Therefore, a drum mixer can be added after the sand making machine, and about 3% of water is evenly added to the drum mixer, which can not only prevent the separation of machine-made sand but also prevent dusting by adding water evenly.

-

Solution 3: Stacking in a more reasonable way

During the stacking of machine-made sand, a step-up inclined stacking layer (inclination angle should not be greater than 1: 3) or a step-up horizontal stacking layer should be established. At the same time, the stacking height of machine-made sand should not be too high (less than 5m). This can effectively reduce the degree of segregation during the accumulation of machine-made sand.

-

Solution 4: Pay attention to loading and unloading

During the loading and unloading of machine-made sand, it should be stacked to the front and back of the rectangular car box at the time of loading, and at the same time at the center of the first and second places. When the dump truck unloads, the coarse material can be mixed with the fine material again. Under the condition of ensuring the stability of the car body, the car body must be raised at a large angle to quickly slide the material backward, which can reduce the occurrence of the material due to roll-off The accumulation of coarse materials to the outside reduces the occurrence of segregation during loading and unloading.

The phenomenon of mechanism sand segregation is more common in production and transportation, but it has a greater impact on the performance of concrete, especially in the case of strict aggregate quality requirements, it may affect the price of sand to a certain extent, so this problem should be caused Attention of producers, take measures to mitigate the occurrence of segregation.