Limestone Sand plant Information

Material: Limestone

Capacity: 100TPH

Output size: 0-2.5mm, 2.5-5mm

Max Feeding Size: 500mm

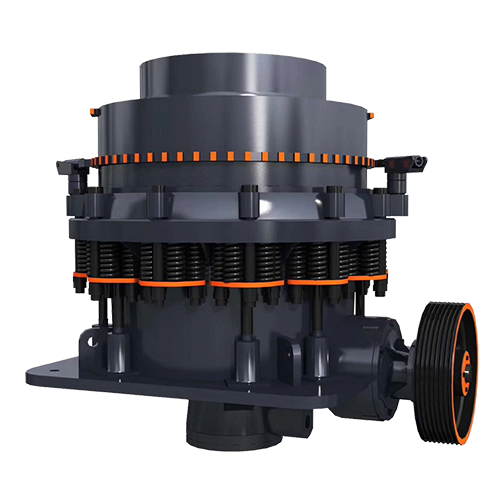

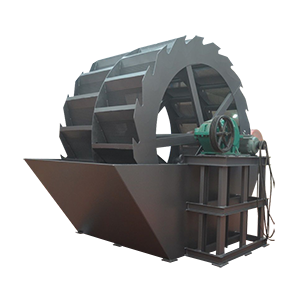

Equipment Configuration: Vibratory Feeder, Jaw Crusher For Primary Crush, Belt Conveyor, Secondary Crusher is Impact Crusher, Iron Seperator, Vibrating Screen, Sand Making Machine.

Project Brief

1. Limestone Introduction

Limestone is the name of limestone as a mineral raw material, is an important road building materials, but also the burning of lime, cement, an important raw material. High-quality limestone after ultra-fine grinding, is widely used in paper, rubber, paint, paint, medicine, cosmetics, feed, sealing, bonding, polishing and other products manufacturing. The compressive strength of limestone is about 150 MPA, which belongs to soft rock. Therefore, the production process of limestone production line selection, sometimes choose jaw crusher or hammer crusher. Eastman crusher is very suitable for crushing limestone, sandstone and other materials, its broken products 95% < 45 mm.

2. Basic Flow

First of all, rocks from the mountain blasting down through the feeder evenly feeding jaw crusher preliminary crushing. After rough crushing, the semi-finished product is conveyed by a belt conveyor to the impact crusher for further crushing. After the second crushing, the stone is transported to the vibrating screen through the belt conveyor to separate out the stones of different specifications. The stones that meet the grain size requirements of customers are transported to the finished product pile by belt conveyor. Larger than the size of the upper screen size of the stones through the belt conveyor back to the impact crusher again broken, forming a closed-circuit cycle.

3. Customer Feedback

The equipment installation of the whole limestone sand production line is simple and not complicated. The finished product has good effect and high energy-saving efficiency.

Our Advantages

➤Professional Engineers Team

Tell us raw material of your aggregate plant, input size, output size, and capacity. Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you. Also, our engineers can design the flowchart according to your needs. Answer any aggregate questions for you.

➤Excellent Crusher Manufacturers

Our company was founded in 1985. In the aggregate crushing industries, we have 35+ years of machinery production of experience. All the equipment of stationary crusher plant, mobile(portable) crusher plant are choose the best materials, and meticulously casting every part. High Performance & Ease of Operation, many crushers equipment in stock.

➤Good Service

We have a office in Tanzania.The customers of regions near Tanzania and Tanzania, we provide installation service for free. All of our equipment, 1 Year Warranty.