Project Profile

Raw Material: River Stone

Capacity: 100TPH

Output size: 0-9.5mm, 9.5-12.7mm,12.7-19mm,19-25.4mm

Max Feed/Input Size: <425mm

Location: Ecuador

Plant Process

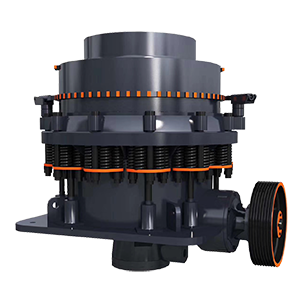

River stones that <425mm fed into vibrating grizzly feeder DN380*95 from hopper. Then evenly fed into jaw crusher PE-500*750 for primary crushed to 50-100mm materials. Symons cone crusher PSGB-0917 was used for river stone secondary crushed. The crushed materials were screened five types size via four-layer Vibrating Screen 4YD1860. 0-9.5mm, .5-12.7mm, 2.7-19mm, 9-25.4mm size are customer needed aggregate. Materials of biger than 25.4mm were transported into Symons cone crusher PSGB-0917 for crushed again by belt conveyor. ▼Download Flowchart PDF

The Crusher Plant Equipment List

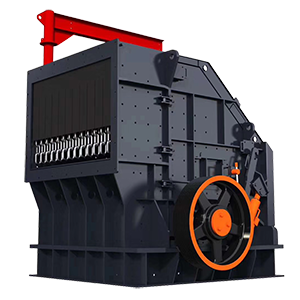

1. Primary Crusher: Jaw Crusher PE-500*750

2. Secondary Crusher: Symons Cone Crusher PSGB-0917

3. Vibrating Feeder Equipment: Vibrating Grizzly Feeder DN380*95

4. Screening Equipment: Vibrating Screen 4YD1860

5. Belt Conveyor: B500*15,B650*20,B500*12

6. Electric Cabinet

Our Advantages

➤Professional Engineers Team

Tell us raw material of your aggregate plant, input size, output size, and capacity. Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you. Also, our engineers can design the flowchart according to your needs. Answer any aggregate questions for you.

➤Excellent Crusher Manufacturers

Our company was founded in 1985. In the aggregate crushing industries, we have 35+ years of machinery production of experience. All the equipment of stationary crusher plant, mobile(portable) crusher plant are choose the best materials, and meticulously casting every part. High Performance & Ease of Operation, many crushers equipment in stock.

➤Good Service

We have a office in Tanzania.The customers of regions near Tanzania and Tanzania, we provide installation service for free. All of our equipment, 1 Year Warranty.